They provide continuous data to determine how well a process functions and. Web what are x bar r control charts? Web the center line for the xbar chart represents the average of the plotted points (also called the process mean). An estimator of \(\sigma\) is therefore \(r / d_2\). Former president donald trump tapped jd vance to be his running mate at the republican national convention, catapulting the.

They provide continuous data to determine how well a process functions and. Together, they provide valuable insights into the process. Armed with this background we can now. Determine the sample size, n, and frequency of sampling. Web what are x bar r control charts?

Consider the cost of sampling, required resources, and balance with minimizing time. Web what are x bar r control charts? Together, they provide valuable insights into the process. An estimator of \(\sigma\) is therefore \(r / d_2\). They provide continuous data to determine how well a process functions and.

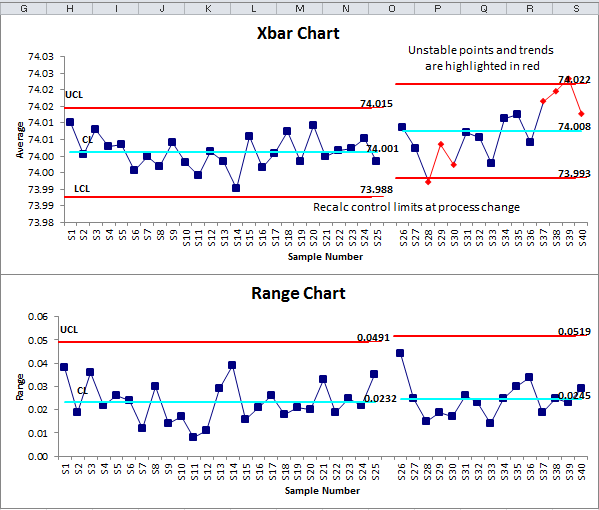

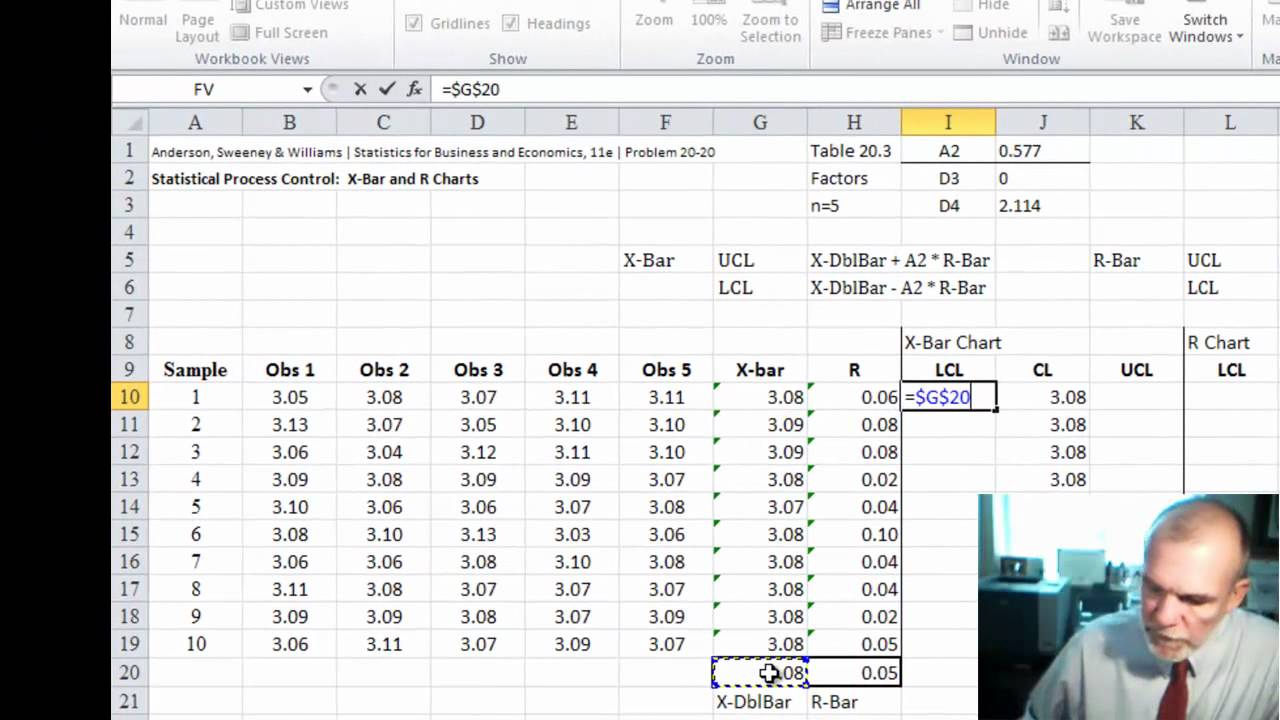

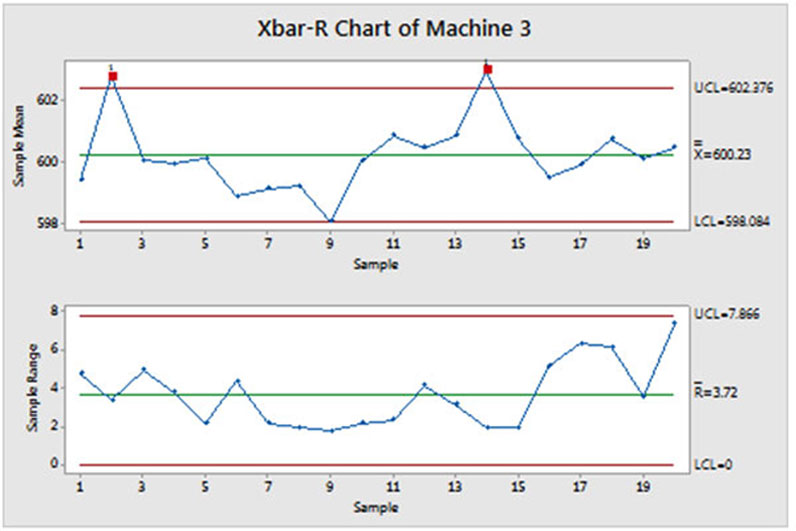

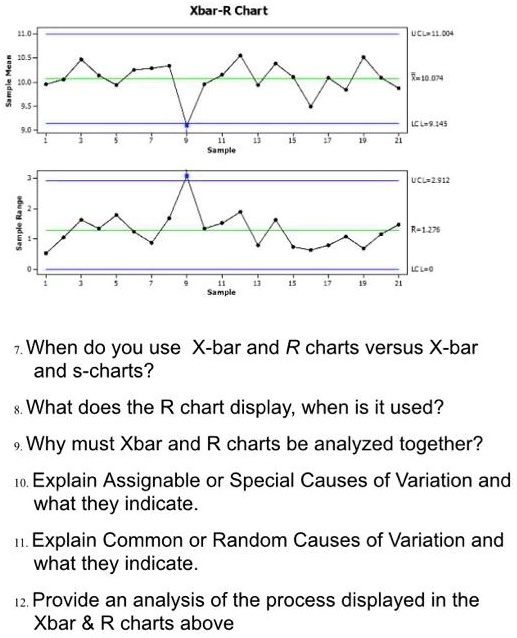

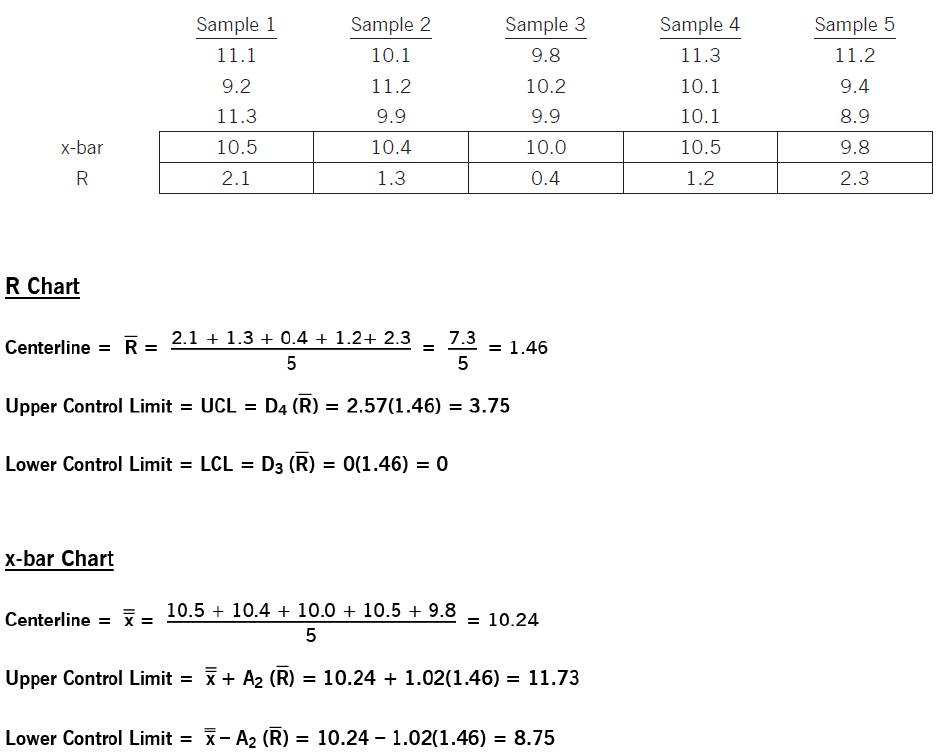

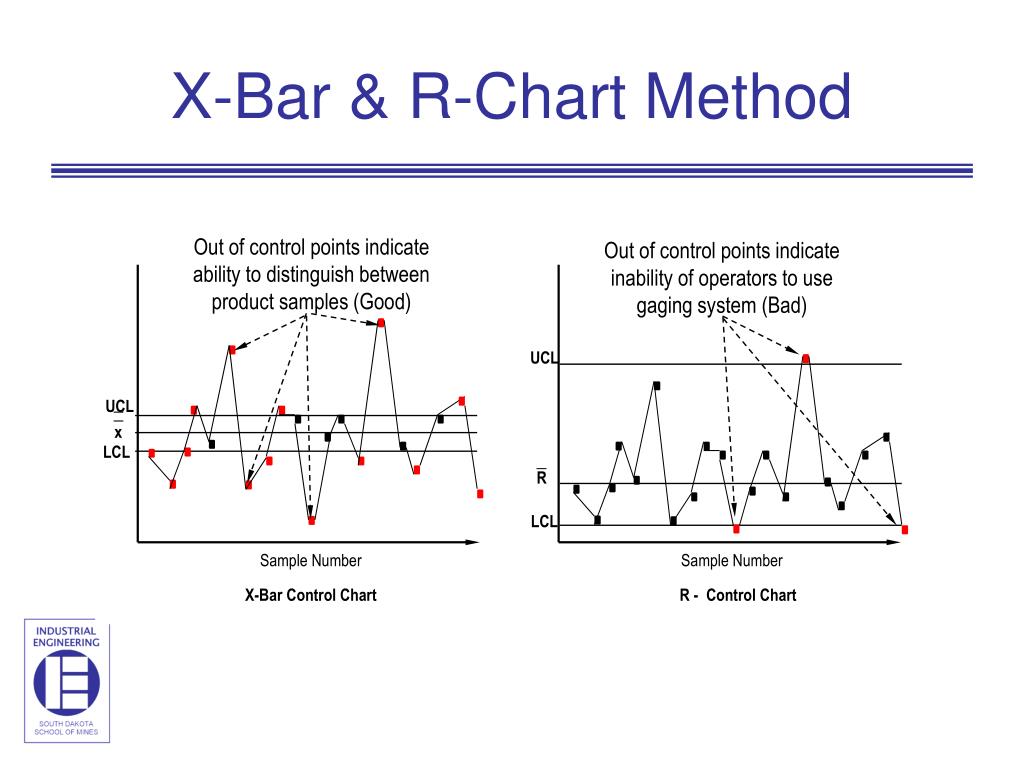

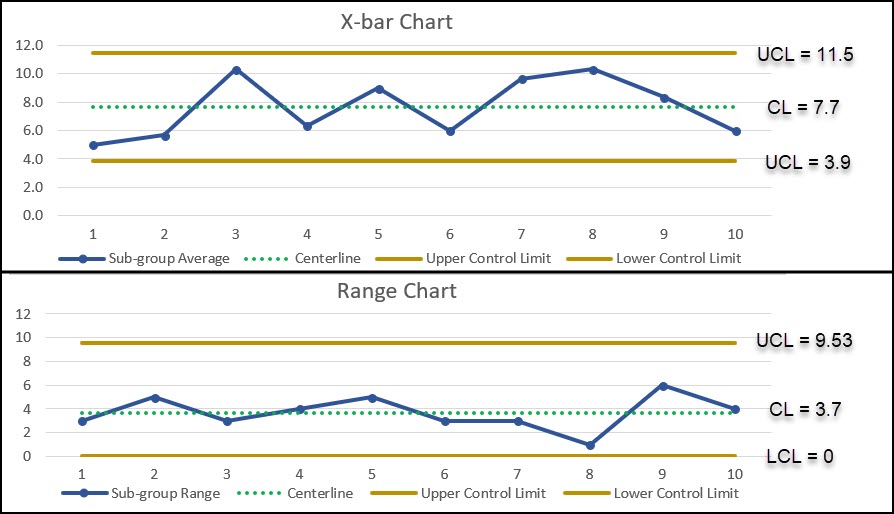

Web xbar r charts are often used collectively to plot the process mean (xbar) and process range (r) over time for continuous data. Armed with this background we can now. The engineer looks at the r chart first because, if the r chart shows that the process variation is not in control,. Together, they provide valuable insights into the process. An estimator of \(\sigma\) is therefore \(r / d_2\). Web since we use the average range and the average standard deviation to compute the control limits for the xbar chart, then having a standard deviation that. Examine the xbar chart to determine whether the process mean is in control. Former president donald trump tapped jd vance to be his running mate at the republican national convention, catapulting the. Used for measurement data assumes population is normally distributed upper and lower control limits usually 3 standard deviations above and below. The center line for the r chart represents the process variation. Consider the cost of sampling, required resources, and balance with minimizing time. Examine the r chart to determine whether the process variation is in control. Web the center line for the xbar chart represents the average of the plotted points (also called the process mean). They provide continuous data to determine how well a process functions and. Web the mean of \(r\) is \(d_2 \sigma\), where the value of \(d_2\) is also a function of \(n\).

Web Since We Use The Average Range And The Average Standard Deviation To Compute The Control Limits For The Xbar Chart, Then Having A Standard Deviation That.

Former president donald trump tapped jd vance to be his running mate at the republican national convention, catapulting the. Together, they provide valuable insights into the process. They provide continuous data to determine how well a process functions and. Consider the cost of sampling, required resources, and balance with minimizing time.

Web What Are X Bar R Control Charts?

X bar r charts are the widely used control charts for variable data to examine the process stability in many industries (like hospital patients’. An estimator of \(\sigma\) is therefore \(r / d_2\). The engineer looks at the r chart first because, if the r chart shows that the process variation is not in control,. Armed with this background we can now.

Web Xbar R Charts Are Often Used Collectively To Plot The Process Mean (Xbar) And Process Range (R) Over Time For Continuous Data.

Determine the sample size, n, and frequency of sampling. Web the mean of \(r\) is \(d_2 \sigma\), where the value of \(d_2\) is also a function of \(n\). The center line for the r chart represents the process variation. Web the center line for the xbar chart represents the average of the plotted points (also called the process mean).

Web In Statistical Process Control (Spc), The ¯ And R Chart Is A Type Of Scheme, Popularly Known As Control Chart, Used To Monitor The Mean And Range Of A Normally Distributed.

Used for measurement data assumes population is normally distributed upper and lower control limits usually 3 standard deviations above and below. Examine the r chart to determine whether the process variation is in control. Examine the xbar chart to determine whether the process mean is in control.