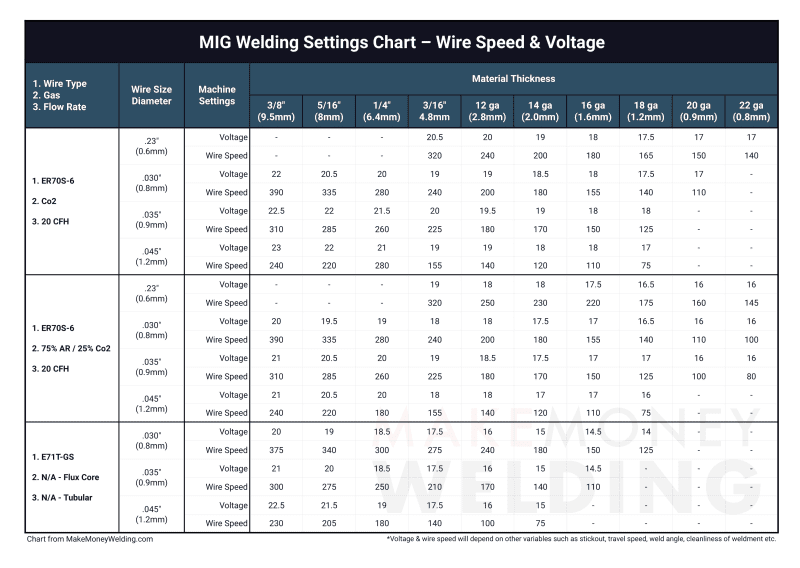

To ensure optimal results, select the appropriate gauge thickness and refer to the corresponding joint gap, wire diameter, amperage, and voltage setting for your weld. Web the most important mig welder settings are voltage, wire feed speed, and shielding gas flow rate. Web lincoln mig welding settings chart. Web an aluminum tig welding settings chart provides essential parameters like amperage and gas flow. Make sure the proper power source is available.

Web flux core welding settings chart. Lincoln stick welder settings for vertical groove welds ( ⅜ in) on this table, a 3/8″ plate requires an arc speed of 5 while the current stays at 150 with a dc polarity. Web an aluminum tig welding settings chart provides essential parameters like amperage and gas flow. Use these tips to get the best mig welds. Before you assemble the mig welder, you need to take care of few things which include:

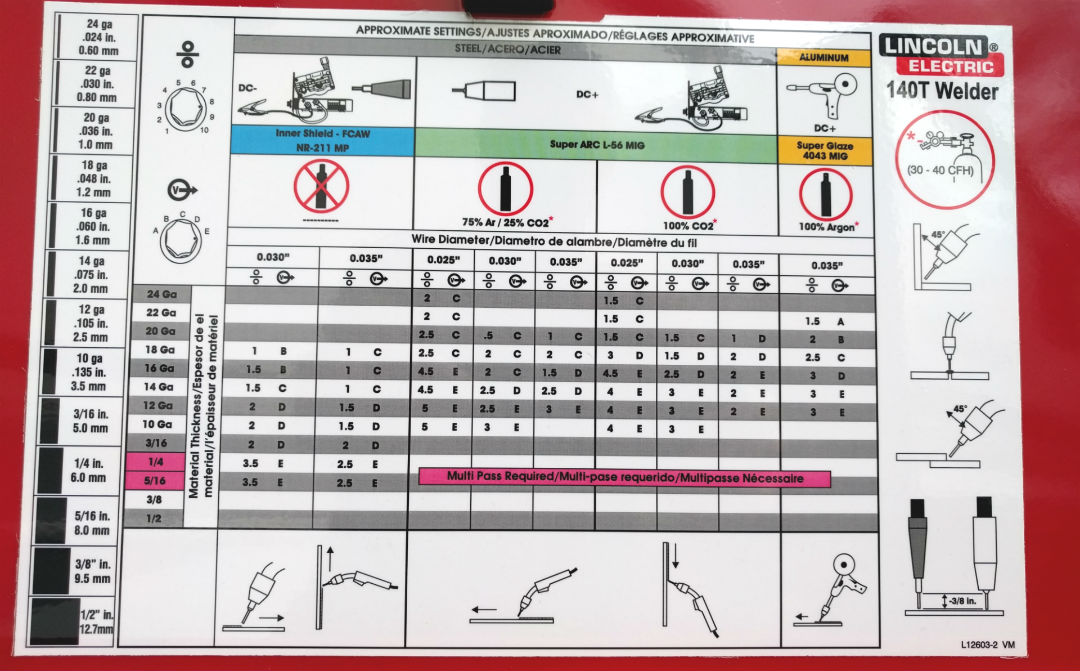

Here is a chart showing the wire speed and voltage speed settings that suit lincoln mig welders. Make sure the proper power source is available. If you have spent some time as a pro or amateur welder, then you might have heard about the lincoln welder. Web find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. Web are you working with a plate thickness of 5/16 in?

Use these tips to get the best mig welds. Web the most important mig welder settings are voltage, wire feed speed, and shielding gas flow rate. Web take a look at the chart below for some starting settings: Web the flux core welding settings chart provides detailed information about the recommended settings for flux core welding, including wire speed, voltage, and polarity. These settings determine the heat, wire deposition rate, and protection from atmospheric contamination, respectively,. Let’s take a look at how to set up a big welder below: A bottle of shielding gas and a gas regulator. Before you assemble the mig welder, you need to take care of few things which include: Once you determine these three main variables, you can set your welding machine and start. Web using the correct mig welding settings can make or break the quality of your finished product. Also, consider the amperage settings and the task at hand. Web a tig welding settings chart provides essential parameters like amperage, voltage, and gas flow. Tig welding, or tungsten inert gas welding, demands precision and control over various settings for optimal results. Web find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. It caters to different material types and thicknesses for effective welding.

Use These Tips To Get The Best Mig Welds.

It caters to different material types and thicknesses for effective welding. It outlines the optimal settings based on material thickness and joint type. Overhead position you should lower the amperage by 5% (and a thinner electrode) Web what metal are you welding?

Once You Determine These Three Main Variables, You Can Set Your Welding Machine And Start.

Web take a look at the chart below for some starting settings: Browse suggested weld parameter settings for tig welding. Here is a chart showing the wire speed and voltage speed settings that suit lincoln mig welders. Web what material are you welding?

Also, Consider The Amperage Settings And The Task At Hand.

Web setting the amperage on a welding machine, whether stick (smaw), mig (gmaw) (*typically uses voltage setting), or tig (gtaw), depends on some key variables such as application and base material, welding process, and electrode. There are many mig setting charts available from manufacturers that all vary. Web are you working with a plate thickness of 5/16 in? Web using the correct mig welding settings can make or break the quality of your finished product.

Lincoln Stick Welder Settings For Vertical Groove Welds ( ⅜ In) On This Table, A 3/8″ Plate Requires An Arc Speed Of 5 While The Current Stays At 150 With A Dc Polarity.

Web find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. Web a tig welding settings chart provides essential parameters like amperage, voltage, and gas flow. Before you assemble the mig welder, you need to take care of few things which include: Thicker base metal use higher amperage.