Web for material smaller than 1/8″ (3.2 mm), a 3/32″ (2.4 mm) rod will be a good choice. For smaw process, weaving shall be 3 times core dia. Compare models and grades to make an informed choice and achieve the best results. Covering classifications, refrence charts and gas choices. The current polarity, power source, thickness of the material, and metal type play a role in tungsten selection.

Welding electrode selection chart for aluminum.pdf In this welding rod chart, you will find over 220 stick electrodes classified according to the american welding society (aws) code. Anything up to 1/4″ (6.35 mm) thick would be best welded with a 1/8″ (3.2 mm) electrode, and thicker metal would use 5/32″ (4.0 mm). The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things. Diameter (inches) diameter (mm) 6010/6011.

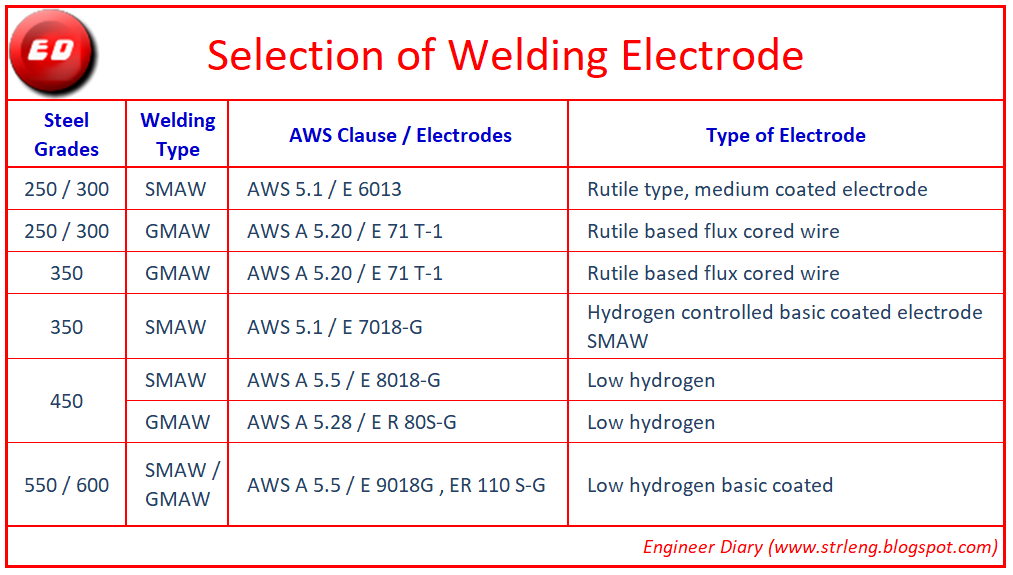

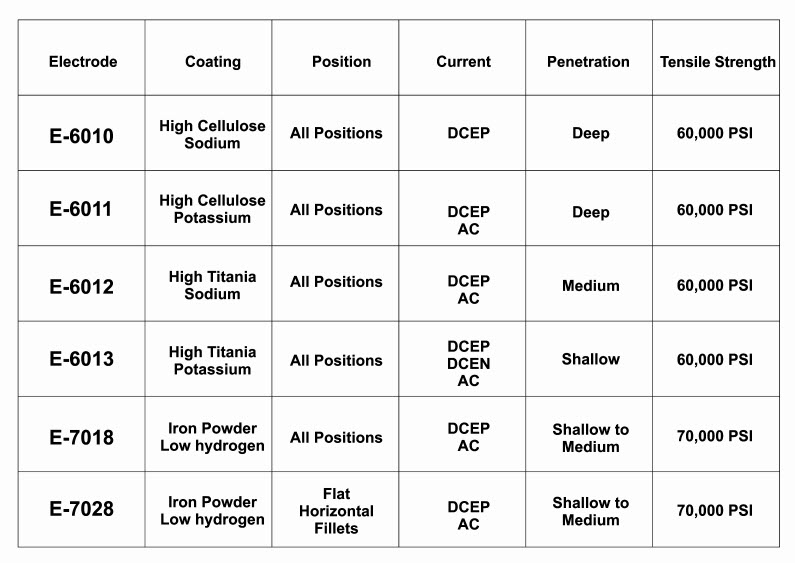

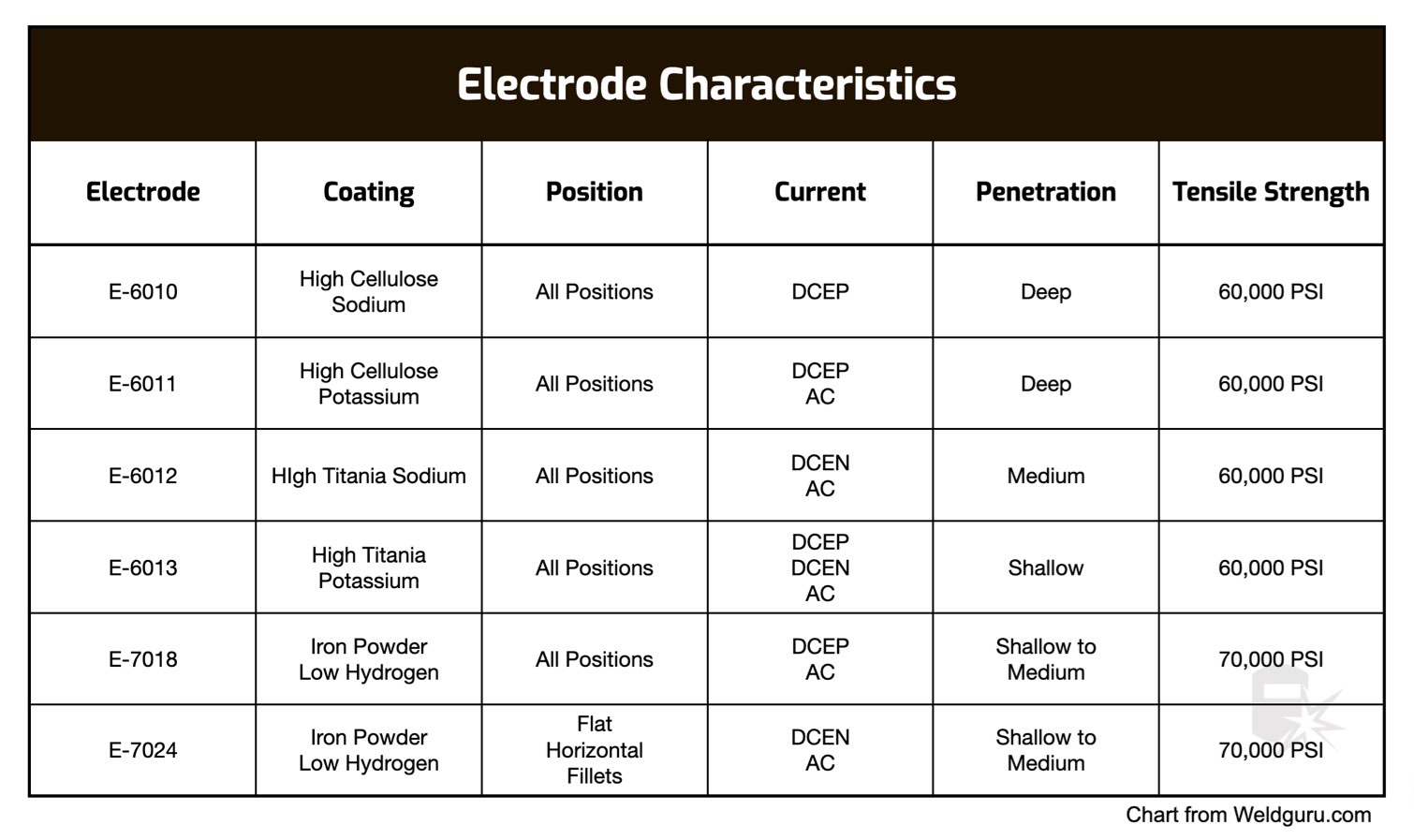

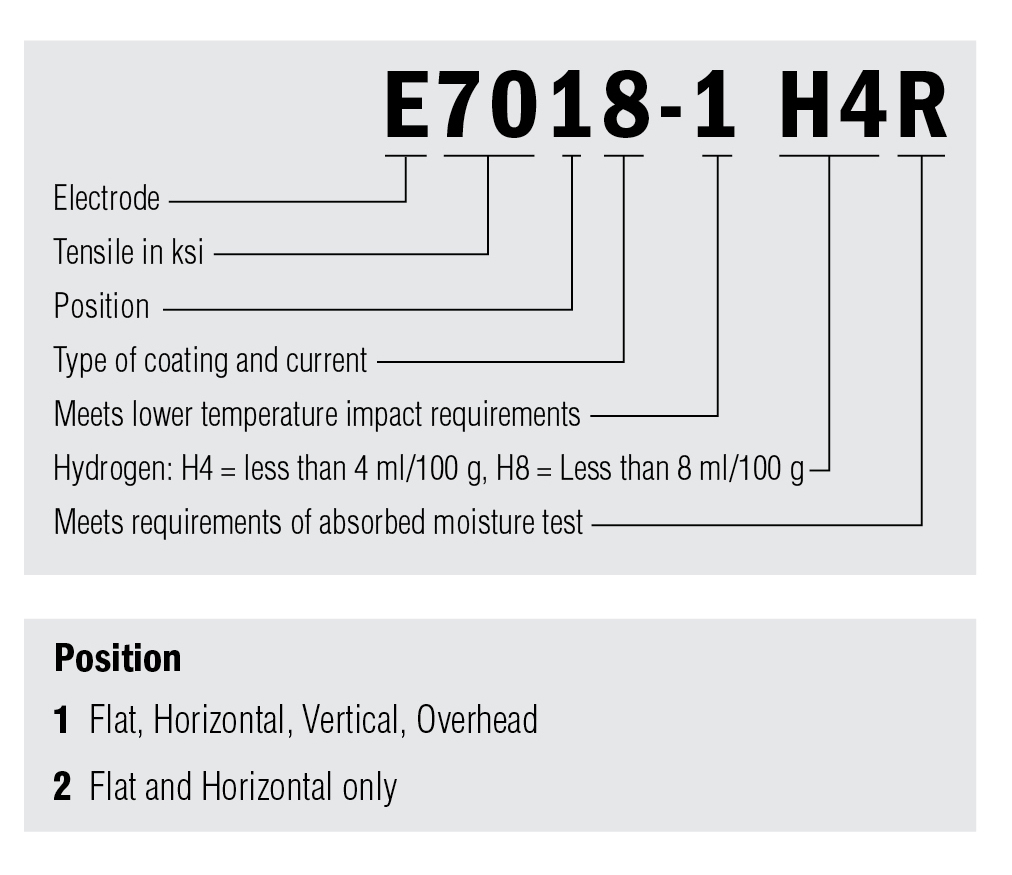

Web welding electrode table (chart) the aws provides a standardized system for classifying welding electrodes. Compare models and grades to make an informed choice and achieve the best results. Web the most popular welding rod sizes for home welders are 3/32″, 1/8″, and 5/32″, as they are suitable for common projects. These include corrosion resistance, ductility, high tensile strength, the type of base metal to be welded, the position of the weld (flat, horizontal, vertical, or overhead), and the type of current and polarity required. It helps you pick the best electrode for your project.

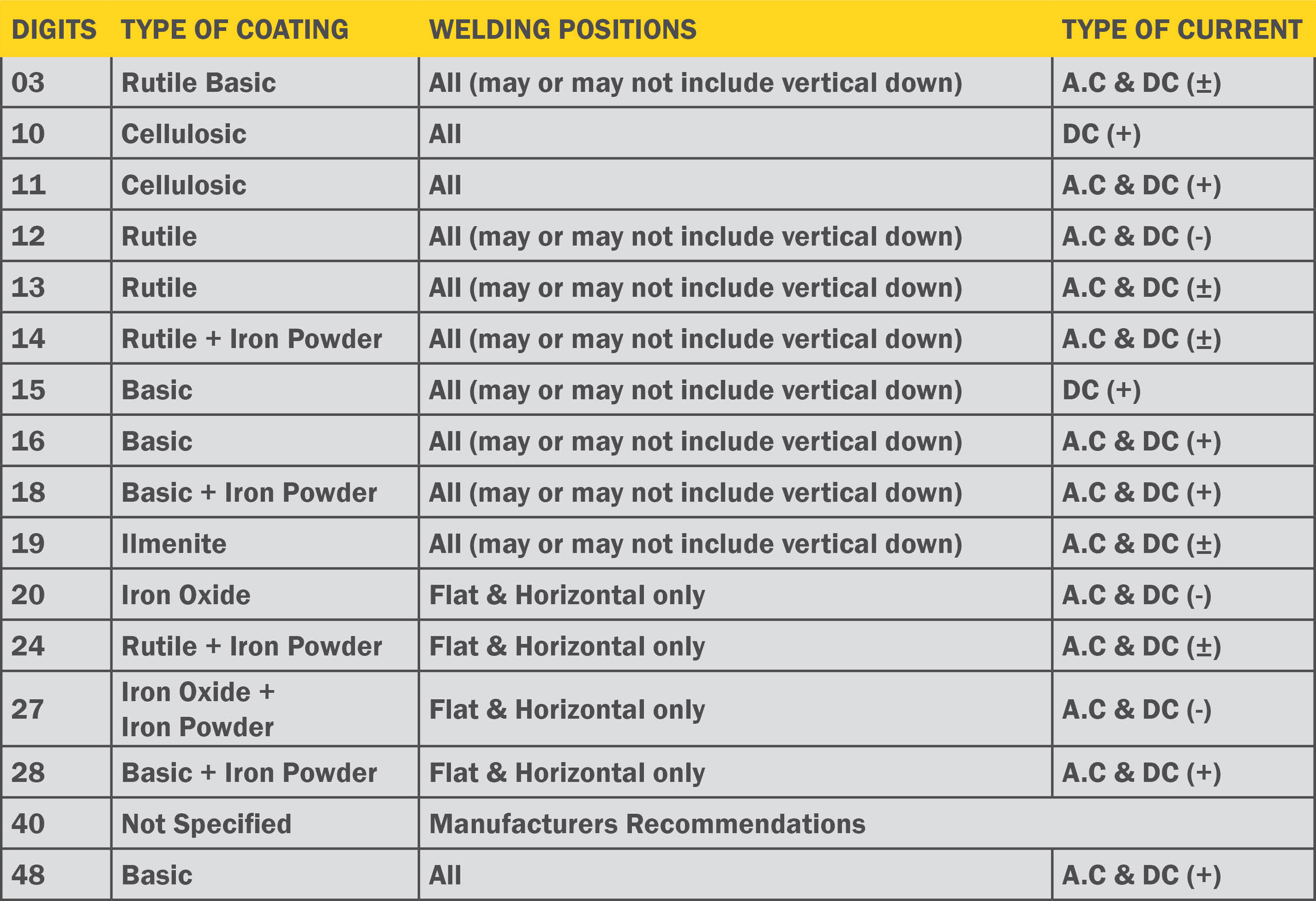

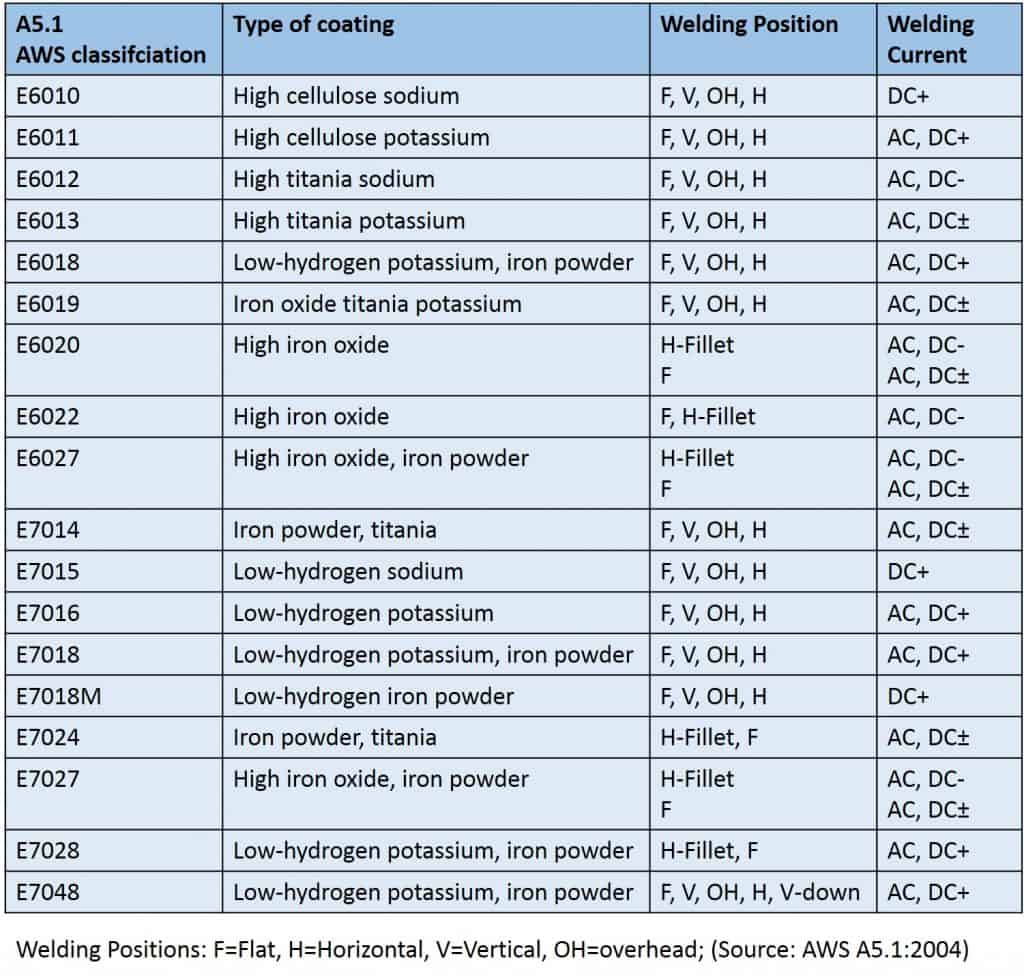

In this welding rod chart, you will find over 220 stick electrodes classified according to the american welding society (aws) code. Diameter (inches) diameter (mm) 6010/6011. In this article, i’ll cover the most common welding rod sizes to help you pick the most suitable one for your needs. It outlines the electrode classification, current settings, and positions applicable for various tasks. Selecting the right tungsten electrode is an essential part of tig welding. For smaw process, weaving shall be 3 times core dia. Web welding connects metals through heat and precision, and the right electrode is vital for a perfect bond. Web complete welding electrode numbers and their coating types, welding positions they can be used and type of welding current are given in the below table (reference: Web stick welding electrodes pdf chart. In this guide, we’ll focus on which electrodes to use for mig/tig and stick welding. The classification is usually presented in the form of a welding electrode table. Covering classifications, refrence charts and gas choices. Web when stick welding, you’ll need to know what the different types of stick welding electrode numbers mean and what applications they’re suitable for. Electrodes for low alloy steel. Welding electrode selection chart for aluminum.pdf

Web Tig Tungsten Electrodes Explained (With Color Chart) By:

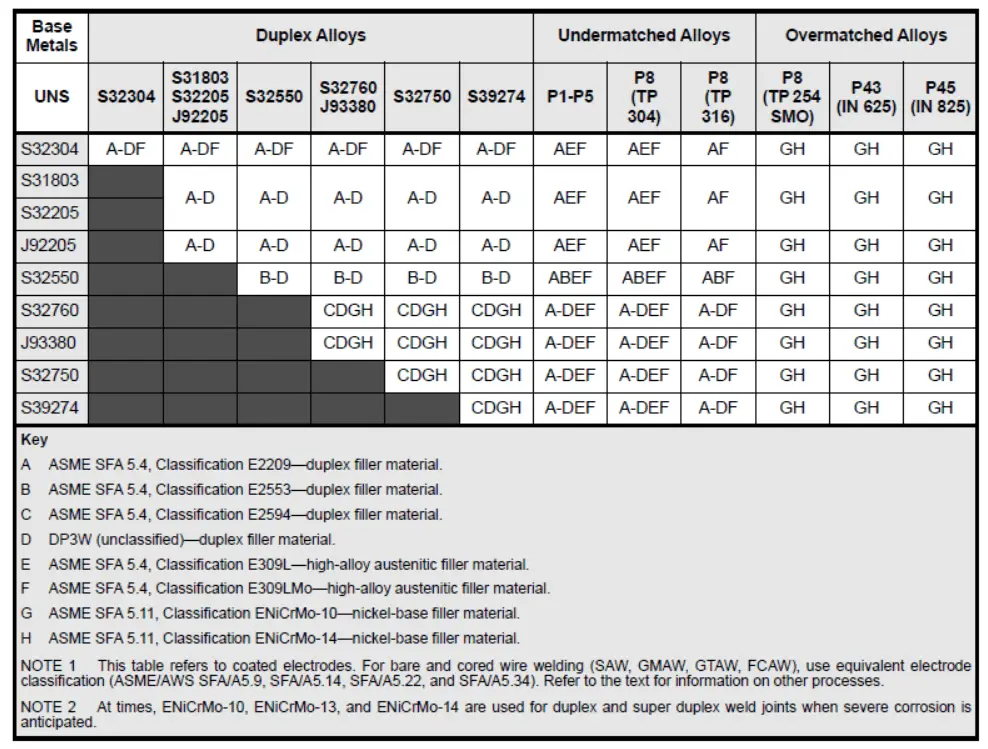

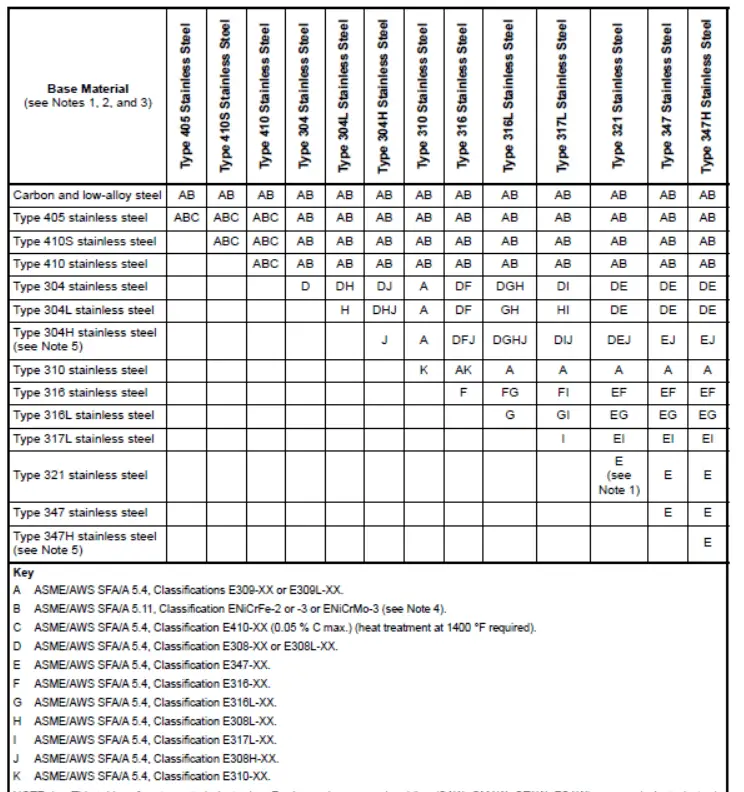

Web electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. Web looking for a welding electrode and filler wire selection chart? In this guide, we’ll focus on which electrodes to use for mig/tig and stick welding. The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things.

Web You Can These Below Welding Electrode Selection Charts To Guide You For Welding Electrode Selection.

The amperage that you choose from the range will come down to a few different factors, but you should use a high amperage on thicker metal and low amperage on thinner metal. Web welding electrode table (chart) the aws provides a standardized system for classifying welding electrodes. Web once you’ve chosen your welding rod diameter, use the stick welding rod chart at the top of the page to find the amperage range for that specific electrode. The current polarity, power source, thickness of the material, and metal type play a role in tungsten selection.

How To Understand Electrode Charts And Codes.

Welding electrode selection chart for aluminum.pdf The classification is usually presented in the form of a welding electrode table. Electrodes for low alloy steel. Welding electrode selection chart.pdf for most commonly used metals.

Anything Up To 1/4″ (6.35 Mm) Thick Would Be Best Welded With A 1/8″ (3.2 Mm) Electrode, And Thicker Metal Would Use 5/32″ (4.0 Mm).

Web for material smaller than 1/8″ (3.2 mm), a 3/32″ (2.4 mm) rod will be a good choice. Below is a chart that will give you a starting point for choosing the correct welding rod size. Web how to select stick welding rod type, size, and amperage. Web mig welding electrode wire selection guide for carbon steel, stainless steel and aluminum alloys.