Web in our guide, you can use our tapcon screw size chart to get the right tapcon drill bit size. L carbide tipped concrete drill bit straight shank 1 pc Before choosing a drill bit for tapcon concrete screws, you should pay attention to two things. Web our concrete screw anchors deliver 30% less torque and 20% more holding power, while our drill bits make it possible to create precise holes at maximum power. Premium hss jobber drill bits.

Web makes installation of tapcon® concrete anchors easy, fast, and accurate. Tool drives 3/16” and 1/4” diameter tapcons. Web when determining the best size of a bit for tapcon screw, there are two dimensions that need to be determined: There are multiple drill bit alternatives to use for different materials or to serve a different purpose. Premium high speed, cobalt & carbide.

Web tapcon concrete screw technical specifications and information. L carbide tipped concrete drill bit straight shank 1 pc Web use different drill bit sizes slightly smaller than the screw diameter to find the best fit and holding power. Web in our guide, you can use our tapcon drill bit size chart to get the right tapcon drill bit size. Web in this guide, i will explain the correct drill bit size to use with 3 8 tapcon.

This page is for information only. Check the packaging or manufacturer’s instructions for more details. Make us your drill bit suppliers, and you’ll never be without a quality drill bit again. Web the ideal drill bit size for a 5/16″ tapcon is generally a 1/4″ bit. Variations in the drill bit size can affect the efficiency of the screw’s installation and the strength of its hold. Web tapcon+ unmatched performance in concrete, block and brick applications make them an excellent alternative to expansion anchors, plugs, lag shields and have a blue corrosion resistant coating that enables them to withstand the harshest conditions. Tool drives 3/16” and 1/4” diameter tapcons. Following these steps will help you determine the right drill bit size for 3/8 tapcon screws accurately. Use the tapcon bits and condrive pro together to install tapcon anchors for optimal performance. Always use the right size drill bit to avoid damaging your foundation. What are the factors that change the tapcon drill bit size? Secure the drill bit in the power drill and make sure it’s aligned and tight. Remember to exercise caution and wear appropriate protective gear while drilling. By the end, you’ll be able to find the right drills and drill bits to get the strongest holding threads that offer an accurate fit, thus obtaining. Premium high speed, cobalt & carbide.

By The End, You’ll Be Able To Find The Right Drills And Drill Bits To Get The Strongest Holding Threads That Offer An Accurate Fit, Thus Obtaining.

Recommended tap drill sizes (for approx. Web use different drill bit sizes slightly smaller than the screw diameter to find the best fit and holding power. Web in this guide, i will explain the correct drill bit size to use with 3 8 tapcon. Web our concrete screw anchors deliver 30% less torque and 20% more holding power, while our drill bits make it possible to create precise holes at maximum power.

Check The Packaging Or Manufacturer’s Instructions For More Details.

Web when determining the best size of a bit for tapcon screw, there are two dimensions that need to be determined: Following these steps will help you determine the right drill bit size for 3/8 tapcon screws accurately. Tool drives 3/16” and 1/4” diameter tapcons. Designed for use with a hammer drill and tapcon drill bits.

These Two Dimensions Should Match The Tapcon Size In Order To Achieve The Required Holding Values.

Web a straight shank tapcon drill bit can be expected to drill 60 holes minimum to a 2 depth in 4,000 psi concrete. Web tapcon sds plus drill bits are specially designed to be compatible with condrive pro installation kit. Web the standard drill bit is universally used for drilling smaller pilot holes in concrete, block and brick, and works seamlessly with tapcon anchors. By the end, you’ll be able to find the right drills and drill bits to get the strongest holding threads that offer an accurate fit, thus obtaining higher tolerances for your concrete anchors.

Video | Tools And Repairs.

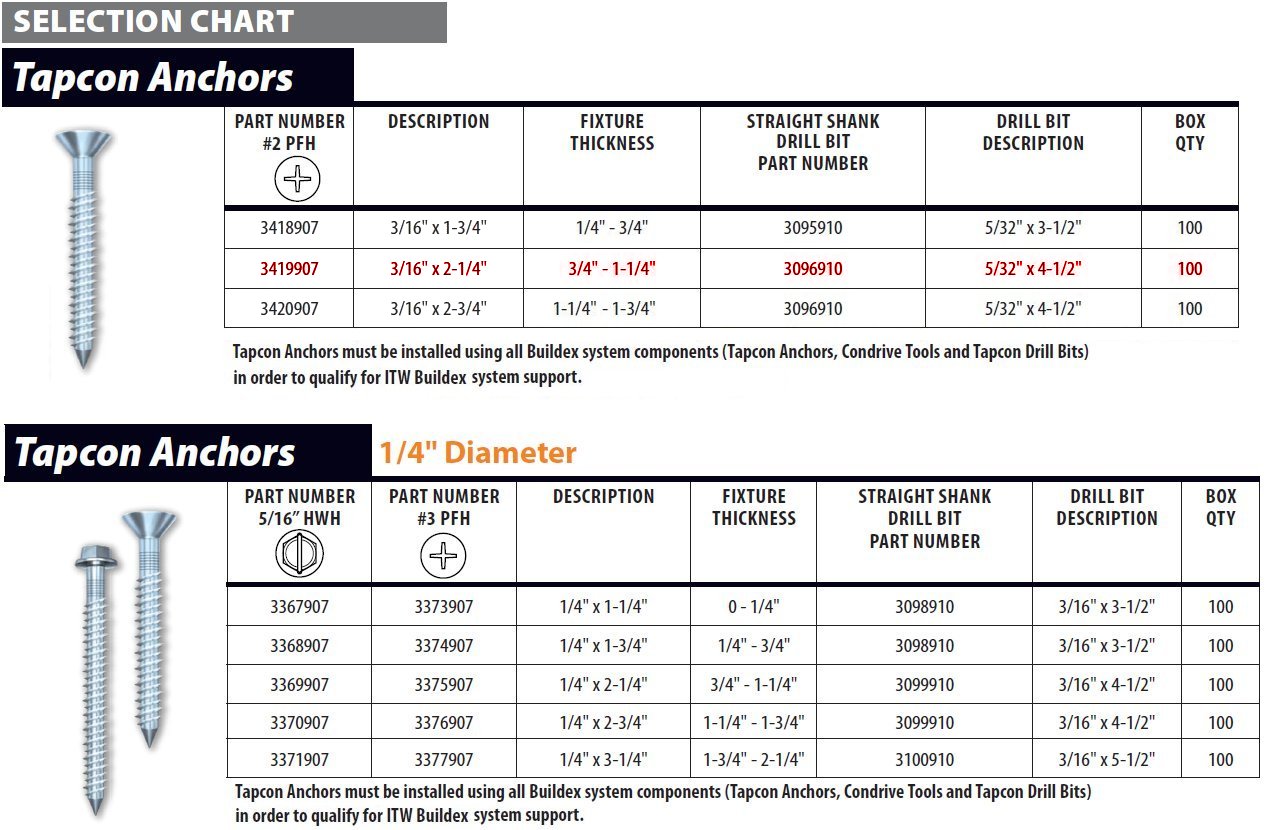

Web the following charts show the diameter and length of the tapcon screw and the diameter and overall length of the carbide bit for the straight shank, sds, sds max, and spline bit. That’s why when pros look for quality, strength and ease of installation, they choose tapcon. Web makes installation of tapcon® concrete anchors easy, fast, and accurate. Web tapcon concrete screw technical specifications and information.