A soldering iron melting solder to join two wires. 152 myrtle avenue jersey city, nj 07305 usa. Another commonly used tin / lead solder alloy is 63/37, which has a melting point of 183 °c. Web as a general rule of thumb, the optimal soldering temperature should be high enough so that when making a solder connection, the solder is approximately 50°c above its melting point. Web soldering irons use a resistor to generate heat to melt solder.

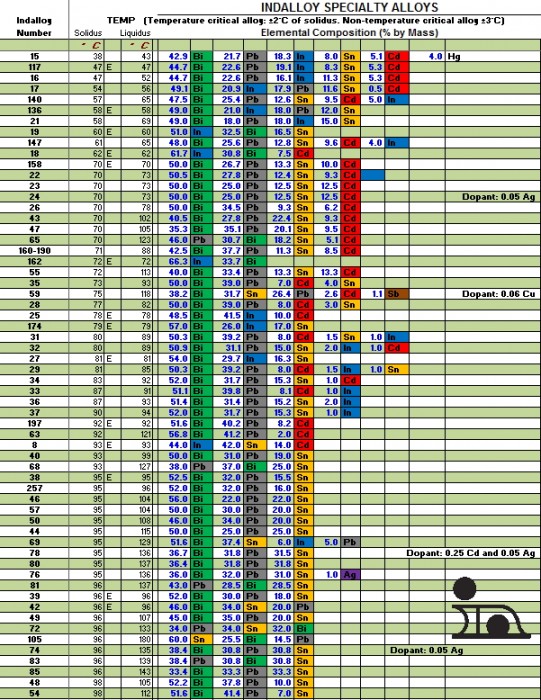

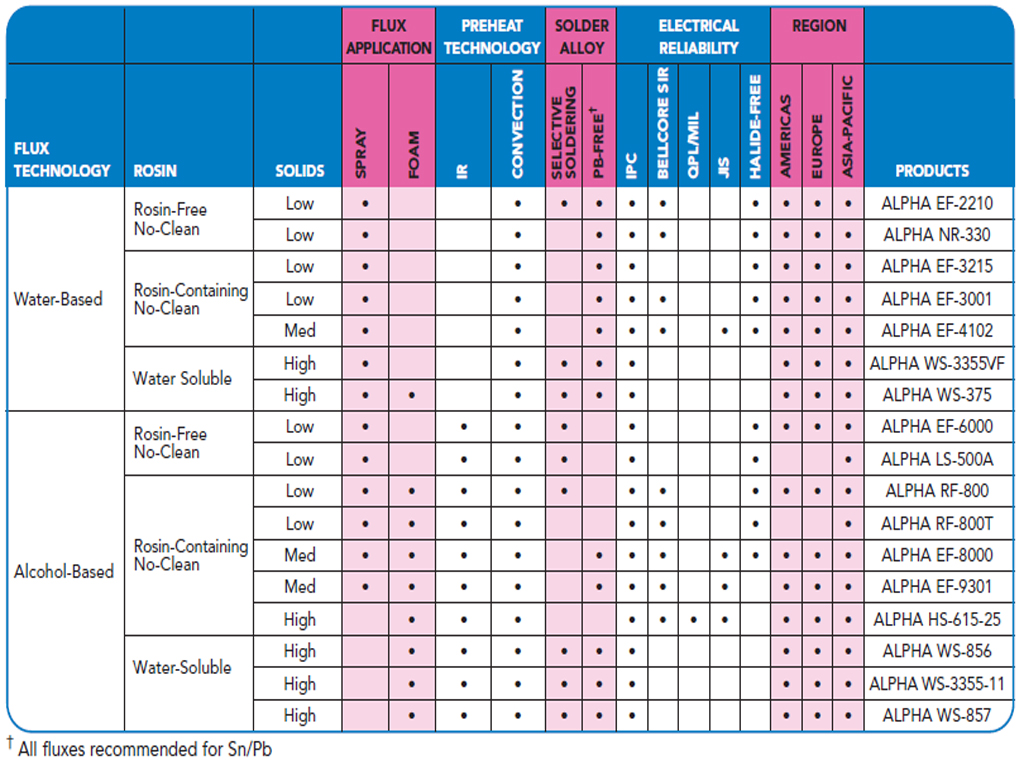

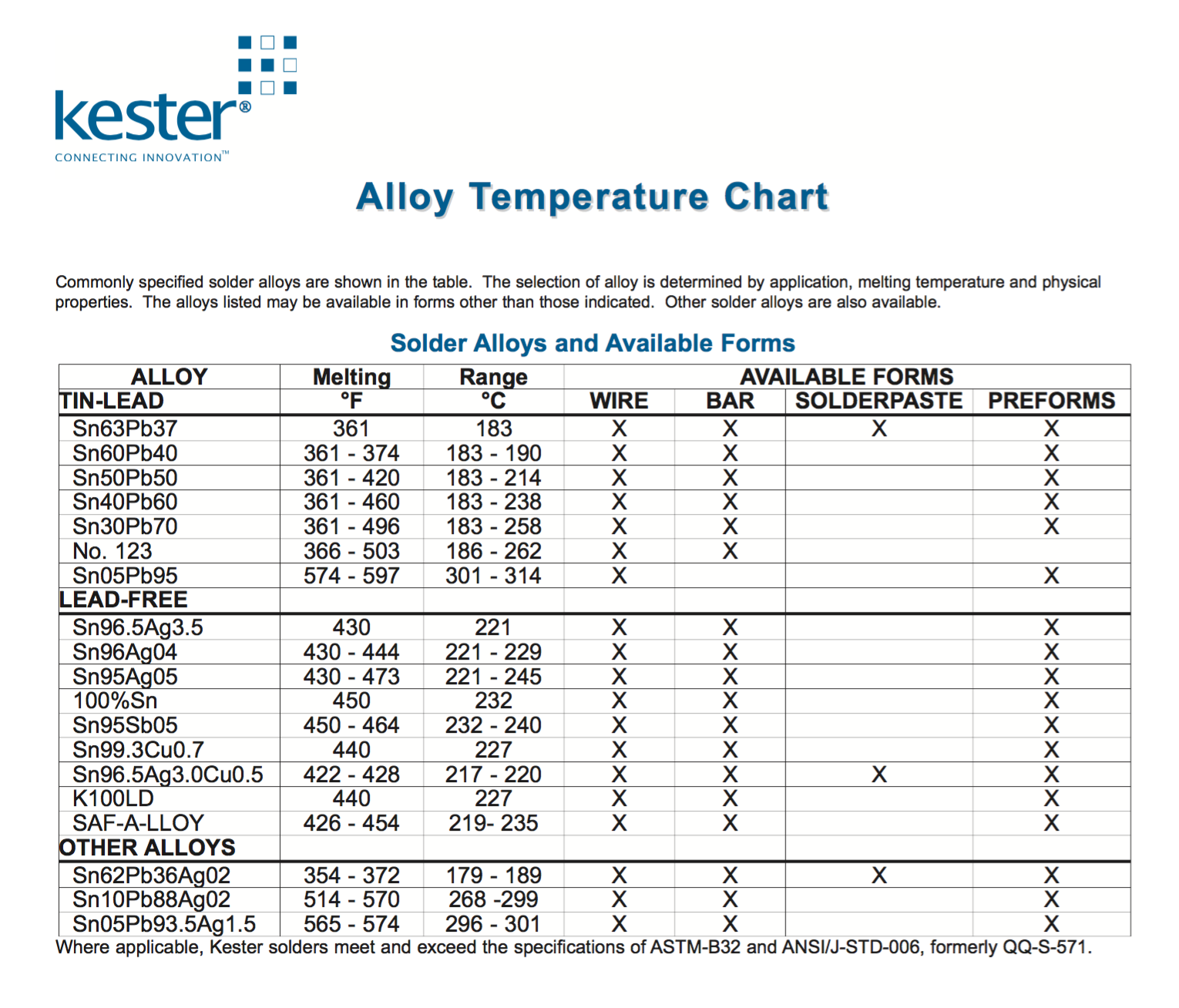

This is a critical factor to consider when soldering, as using a solder with the wrong melting point can lead to weak or incomplete joints. Commonly specified solder alloys are shown in the table. Web when soldering surface mount components, a small tip and 600f (315c) should be sufficient to quickly solder the joint well without overheating the component. A composition of tin (30%) and lead (70%) turns into liquid at a higher temperature of 491°f (255°c) due to the high lead concentration. Melting temperature solidus liquidus tin lead silver other degrees c degrees f 60 36 4 179.

This is a critical factor to consider when soldering, as using a solder with the wrong melting point can lead to weak or incomplete joints. This chart includes the alloy’s melting temperature and lists the available forms for each alloy. See my handy tip for holding solder while manually soldering. The selection of alloy is determined by application, melting temperature and physical properties. It helps to hold down the component with tweezers or a pointed probe so it doesn’t blow away.

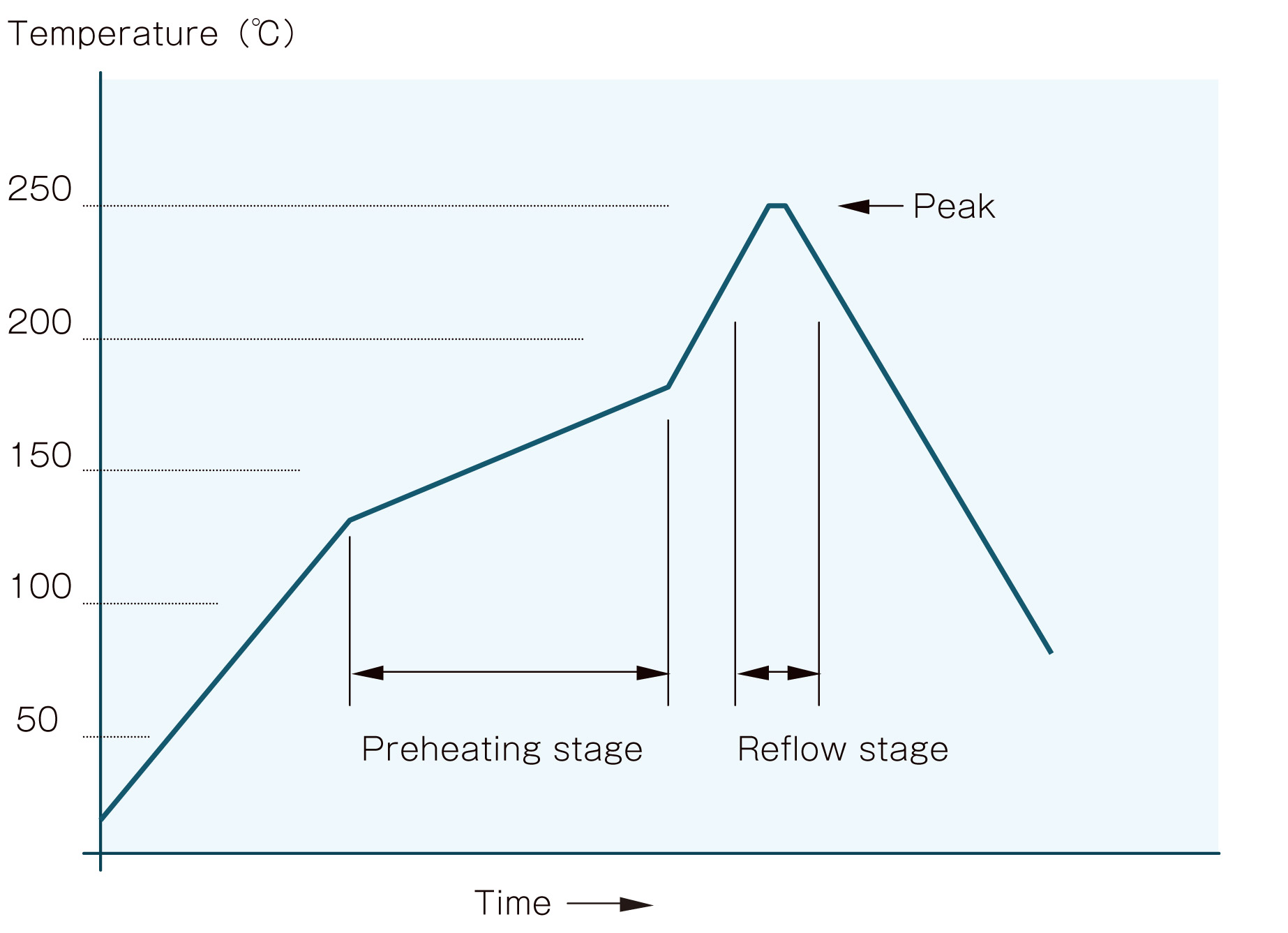

A 60/40 solder is an alloy of 60 % tin and 40 % lead measured by weight. This chart includes the alloy’s melting temperature and lists the available forms for each alloy. This can be used for several applications, and the temperatures they can reach vary depending on the solder and their intended purpose. The melting point of the solder depends mostly on its alloy formulation. Place the paste carefully on the pads before placing the component, then use the hot air to melt the solder paste. This type of solder has a melting point of around 190 °c. Web most solder melts around 180 to 190 degrees celsius, that is 360 to 370 degrees fahrenheit. Web the melting temperature for alloy solder, which is the most common type of solder, is around 360 to 370 degrees fahrenheit (or 180 to 190 degrees celsius, if you’re accustomed to using the metric system). Web bright solder joints, improved wetting. Web the alloy temperature chart lists the alloys that are available from kester. Web turn on the soldering iron and set temperature above the melting point of your solder. These are the more commonly used alloys. In this article, i will cover some topics to help you better understand these practical tools. Web as a general rule of thumb, the optimal soldering temperature should be high enough so that when making a solder connection, the solder is approximately 50°c above its melting point. When soldering through hole components, 700f (370c) is useful to pump more heat into the wire and plated hole to solder it quickly.

Web This Guide Covers The Significance Of The Melting Point Of Solder, Why It’s Important, Factors Affecting It, Common Solder Alloys, And Tools For Measuring Solder Melting Temperature.

This type of solder has a melting point of around 190 °c. This chart includes the alloy’s melting temperature and lists the available forms for each alloy. Commonly specified solder alloys are shown in the table. Lead solders usually melt between 180 and 190 0 c (see table 1).

Selecting A Soldering Temperature For Your Iron.

Other solder alloys are also available. In this article, i will cover some topics to help you better understand these practical tools. 152 myrtle avenue jersey city, nj 07305 usa. Excellent alloy for soldering stainless steel.

So We Have To Get The Solder Joint Hotter Than This.

These are the more commonly used alloys. It helps to hold down the component with tweezers or a pointed probe so it doesn’t blow away. This study investigated the thermal fatigue reliability of ball grid array (bga) solder joints under accelerated thermal cycling, considering the impacts of solder alloy and temperature profile. See my handy tip for holding solder while manually soldering.

Web Solder Melting Point Refers To The Temperature At Which A Given Type Of Solder Will Melt And Flow Into The Joint Being Soldered.

Commonly specified solder alloys are shown in the table. Web when soldering surface mount components, a small tip and 600f (315c) should be sufficient to quickly solder the joint well without overheating the component. The set temperature for a soldering station should be an additional 70°c to 100°c higher to provide a heat reserve for the quick thermal recovery of the tip. Other solder alloys are also available.