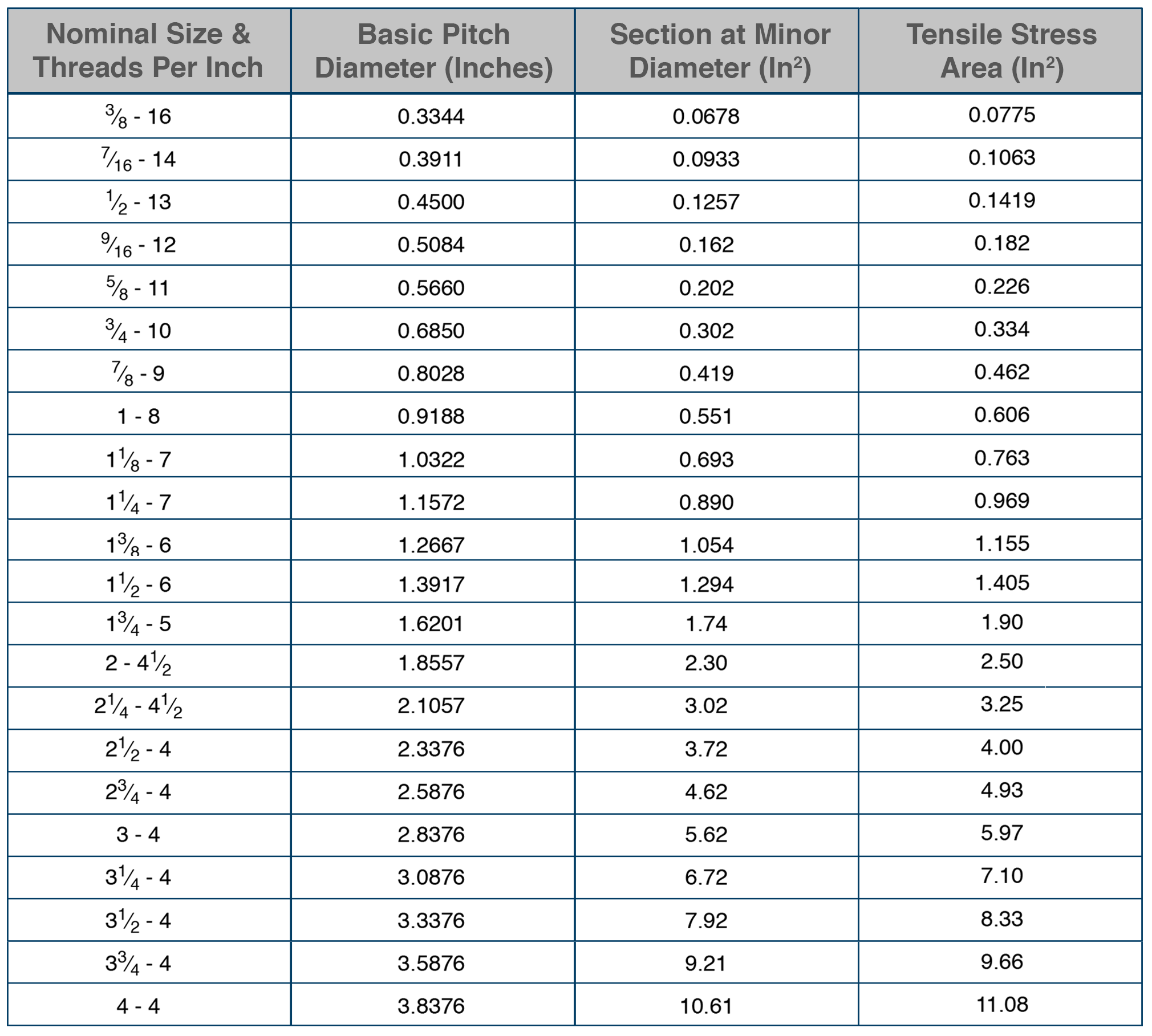

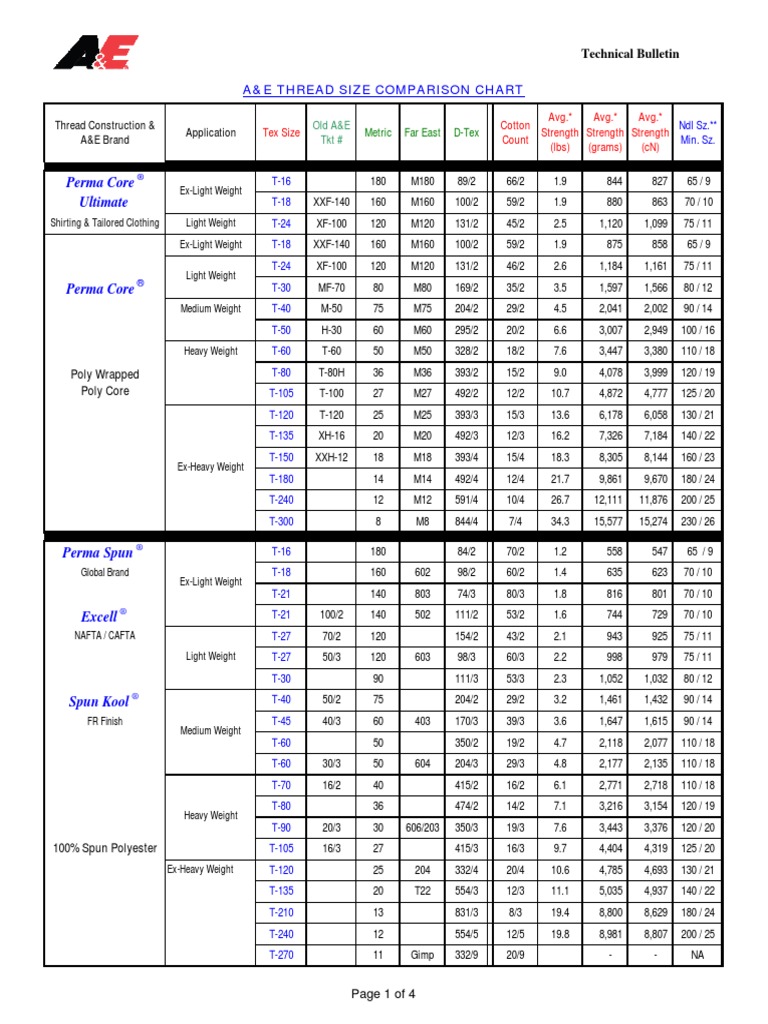

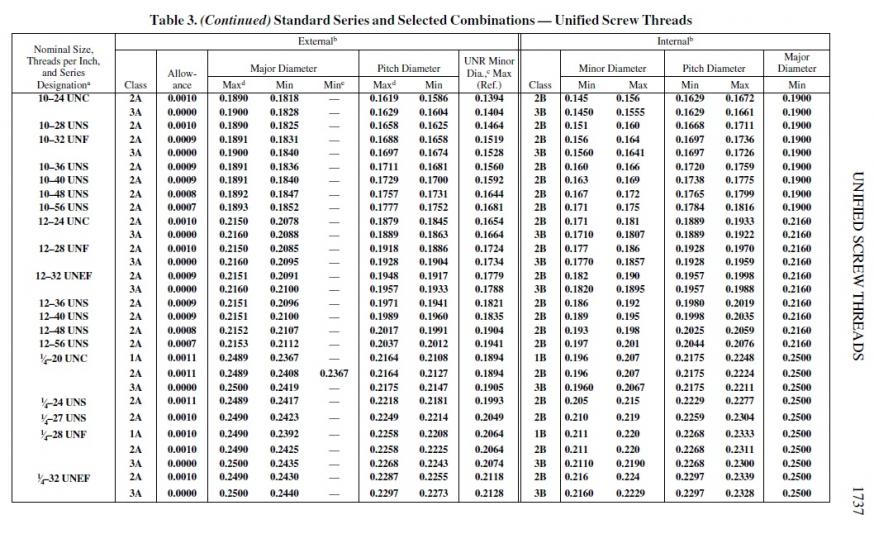

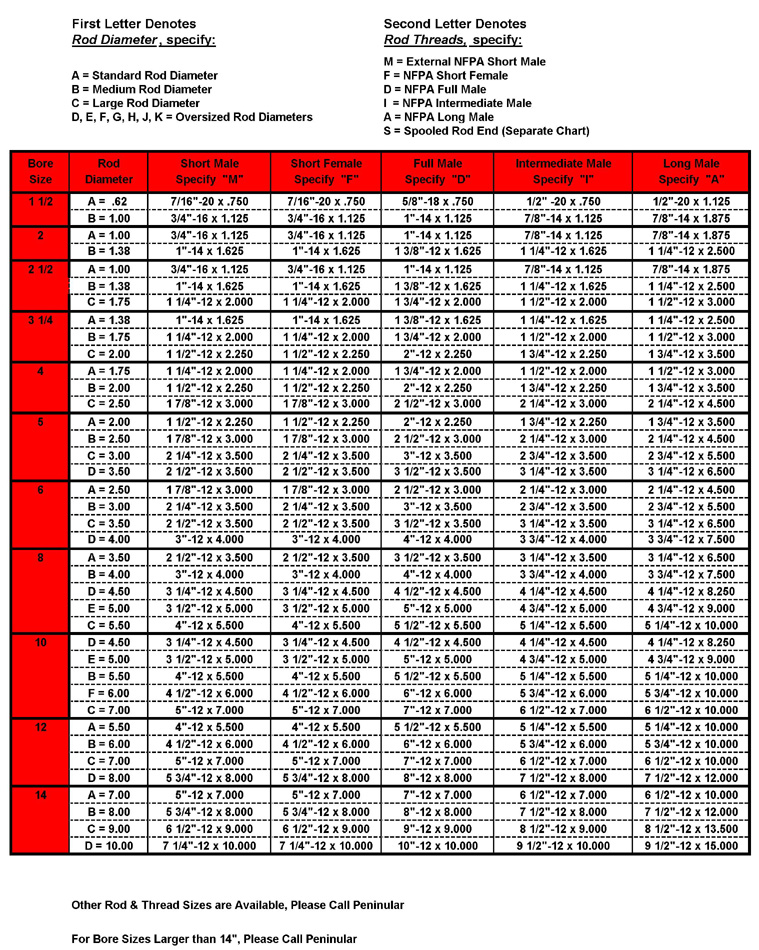

Web the tolerance for the major diameter changes with the class of thread, so charts should be referenced when threads must meet specific requirements. Web the ulitmate metric screw thread resource: The chart in table 2 describes how to determine the size of unified male threads when making a bolt or threaded pipe. The id's or tap drill sizes are what's. The die is applied to a specific diameter of rod for.

Web the hex dies that are standard die size, like 1 across the flats, are for cutting new threads on solid bar. Basic dimensions, classes, tolerances, formulas, charts, and explanations. Web you need to determine the class of fit because this determines the rod size used before cutting the thread. Web there is no dought that reducing the stated size of a tap or die will reduce effort threading but will also reduce thread depth and strength. Guiding the die rigidly is one of the.

The id's or tap drill sizes are what's. The die is applied to a specific diameter of rod for. See what drills are contained in drill sets. Web expecting a die to follow its nominal sized rod for any distance is dreaming, especially if the die is old and worn or of poor quality. Web the size rod you will need is the major diameter of the thread you will be cutting with the die.

Web this question may seem very elementary to many here, but i've been trying to find some kind of chart that will tell me what the starting diameter of a rod should be for. Web you need to determine the class of fit because this determines the rod size used before cutting the thread. Guiding the die rigidly is one of the. Web the size rod you will need is the major diameter of the thread you will be cutting with the die. Just find the thread on the chart and go by the major diameter. Web using a nut or thread measuring wires will tell you when you have cut the thread deep enough. Web i would like to cut some m8 x 1.25 threads on the end of a 5/16 rod (1145 cold formed) using a die. Web pipe thread drilled hole sizes. The tap/drill chart ed posted will tell you the size hole you need to. Web i am trying to find a chart that tells you what size diameter rods you start with, when using dies to cut male threads on them, based on the die's threading info. Find the right rod size for threading with a die. The chart in table 2 describes how to determine the size of unified male threads when making a bolt or threaded pipe. Web i have all the tap drill sizes for taps on my handy wall chart and the densely packed info sheet in my tap and die set but nothing for dies. Web if you measure some bolt thread diameters, they will tend to be a little undersize. Rod size for die threading.

Web If You Measure Some Bolt Thread Diameters, They Will Tend To Be A Little Undersize.

Die blank size is the major. Web the size rod you will need is the major diameter of the thread you will be cutting with the die. That is a difference in the class of fit. Web expecting a die to follow its nominal sized rod for any distance is dreaming, especially if the die is old and worn or of poor quality.

Guiding The Die Rigidly Is One Of The.

Basic dimensions, classes, tolerances, formulas, charts, and explanations. Web dies are used to make external threads on a rod, creating a threaded surface that allows a bolt to be fastened to it. Just find the thread on the chart and go by the major diameter. Web the tolerance for the major diameter changes with the class of thread, so charts should be referenced when threads must meet specific requirements.

The Id's Or Tap Drill Sizes Are What's.

Web this question may seem very elementary to many here, but i've been trying to find some kind of chart that will tell me what the starting diameter of a rod should be for. Note that a class 2a is a looser fit than a 3a and the. The die is applied to a specific diameter of rod for. Web find tap drills, thread specs, and clearance drills.

Web A Rod Size For Thread Die Chart Is A Reference Table That Provides The Appropriate Rod Size To Use When Creating Threads Using A Thread Die.

Web the hex dies that are standard die size, like 1 across the flats, are for cutting new threads on solid bar. Web using a nut or thread measuring wires will tell you when you have cut the thread deep enough. The chart in table 2 describes how to determine the size of unified male threads when making a bolt or threaded pipe. This is all important when using a die because if the rod is exactly 0.375, or in the case of hot.