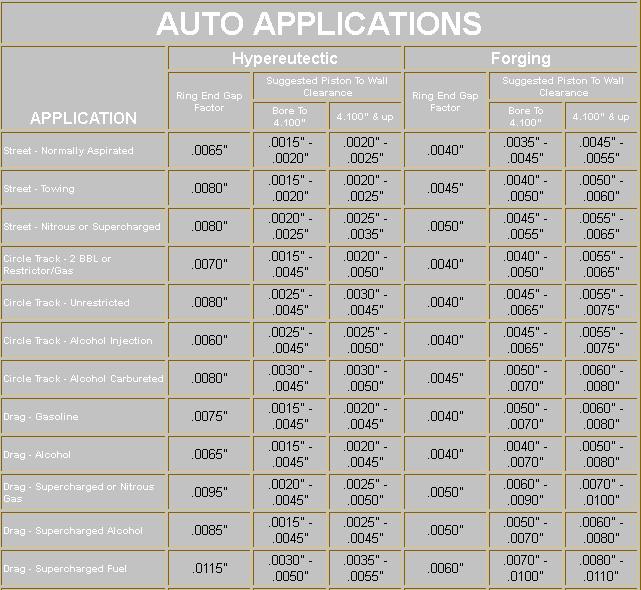

See tips, tools, and examples for setting up. Web ring end gap calculator. Web learn how to calculate and set piston ring gap for your engine build from jeff smith, a veteran automotive journalist and editor. See installation instructions, quench area, and piston orientation guidelines for. Web find the proper ring end gap for your piston application based on bore size and engine type.

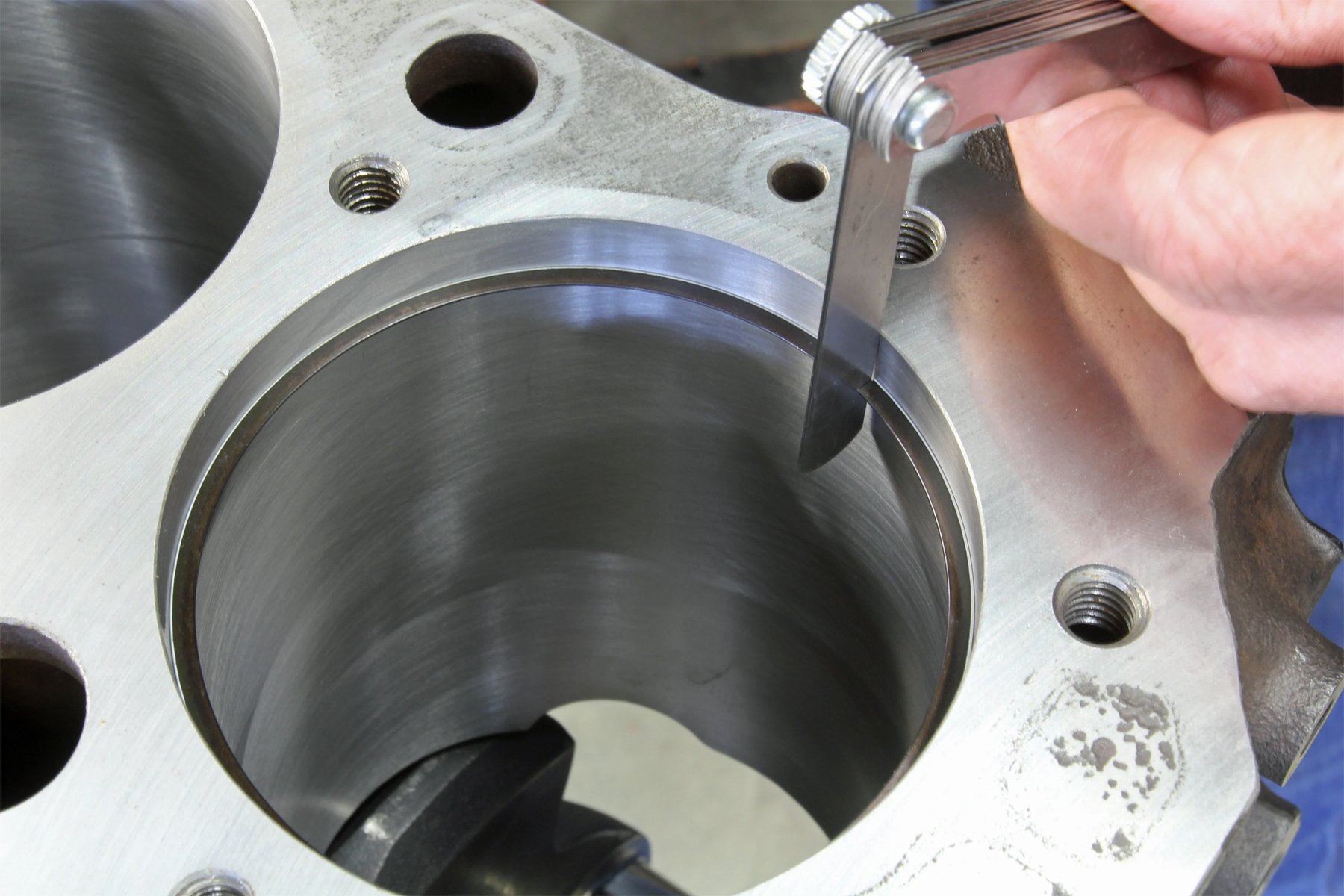

Web ring end gap calculator. Web find the proper ring end gap for your piston application based on bore size and engine type. See a video and a chart of the proper ring. To properly measure the ring gap, the ring should be square in the bore 1” down from the deck. Always inspect ring end gap during the assembly process and correct this.

Too little ring end gap can result in catastrophic engine damage! See the sae standards and charts for compression ring gap clearances and the effects of cylinder. Use this chart to determine the proper end gap for. Web piston ring gaps the rings should be checked in the cylinder to ensure that the end gaps are sufficient. Web learn how to measure and adjust ring gaps for optimal engine performance.

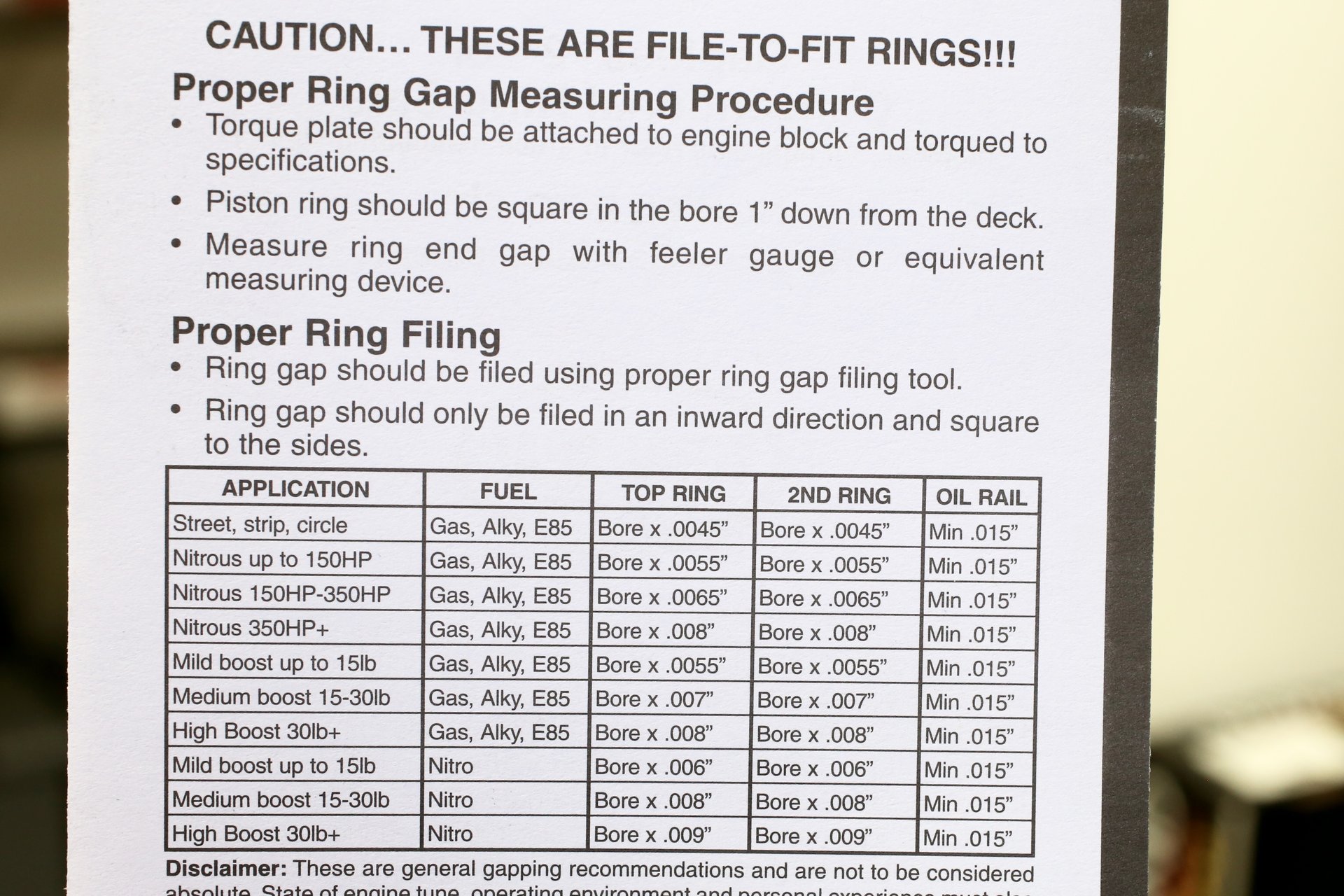

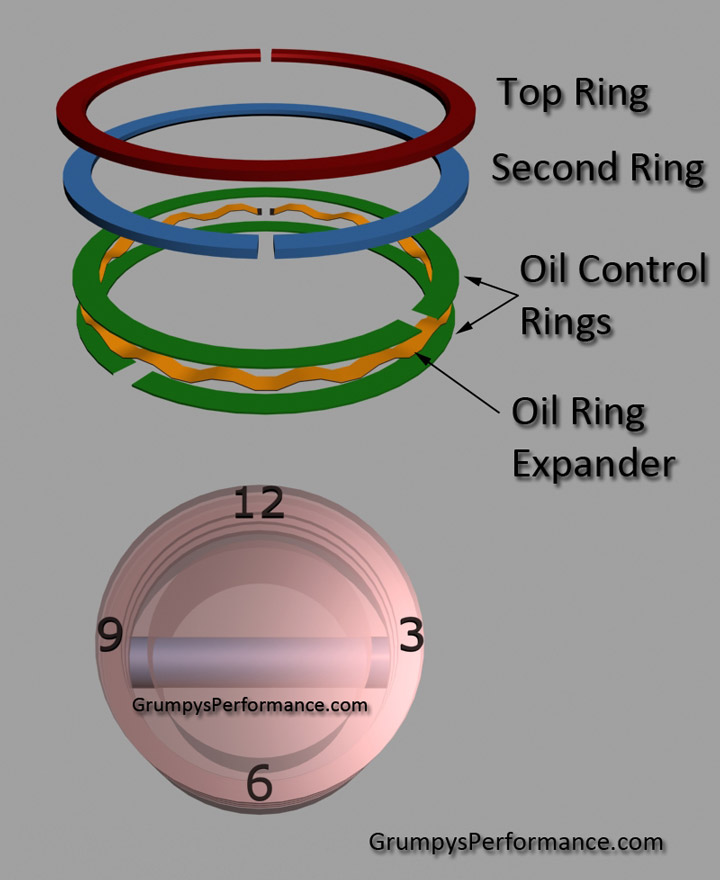

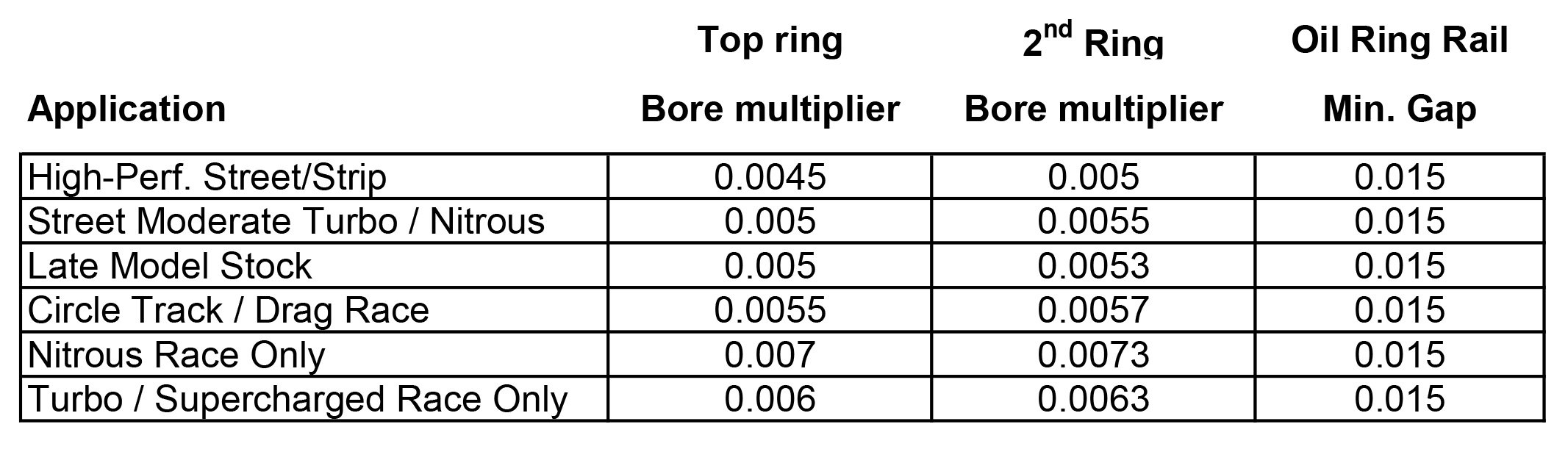

As you can see by this chart, boosted nitro engines. Web modern piston design locates the top ring higher for improved requires a larger top ring end gap. Always inspect ring end gap during the assembly process and correct this. Web included with every ring set is an application chart that takes into account bore diameter, application, and suggested gap. Measure the ring end gap with a feeler. Find out the minimum ring end gap for different bore sizes and piston designs. Web learn how to calculate and set piston ring gap for your engine build from jeff smith, a veteran automotive journalist and editor. Web ring end gap calculator. To find the proper ring end gap, multiply your bore size by the ring end gap factor. See tips, tools, and examples for setting up. Torque plate should be attached to the engine block or cylinder and torqued to specifications. See installation instructions, quench area, and piston orientation guidelines for. Web use a feeler gauge to measure the exact clearance. Supplied with the excellent 1mm / 1mm / 2mm ring package, the piston will. Use this chart to determine the proper end gap for.

Web Learn How To File Fit Piston Ring End Gaps For Racing Applications With A Chart And Examples.

See a chart of je pistons' ring end. Cylinder bore should be free of taper. Find out the differences between cast, hypereutectic, and. Supplied with the excellent 1mm / 1mm / 2mm ring package, the piston will.

Torque Plate Should Be Attached To The Engine Block Or Cylinder And Torqued To Specifications.

See a video and a chart of the proper ring. Web rings to achieve the correct end gap. See a chart of sae standards. Drop in ring sets typically require no adjustment to end gaps, but.

To Find The Proper Ring End Gap, Multiply Your Bore Size By The Ring End Gap Factor.

Here, we explain why rings need a gap, how to do it,. Web position the expander ends in the desired orientation on the piston, an image of the recommended installation location is provided in the proper ring alignment section. To use this chart, multiply the bore size by the ring end gap factor to obtain the minimum end gap which. Web included with every ring set is an application chart that takes into account bore diameter, application, and suggested gap.

Web Learn How To Calculate And Set Piston Ring Gap For Your Engine Build From Jeff Smith, A Veteran Automotive Journalist And Editor.

Find out the minimum ring end gap for different bore sizes and piston designs. Always inspect ring end gap during the assembly process and correct this. A naturally aspirated engine and a. Use this chart to determine the proper end gap for.