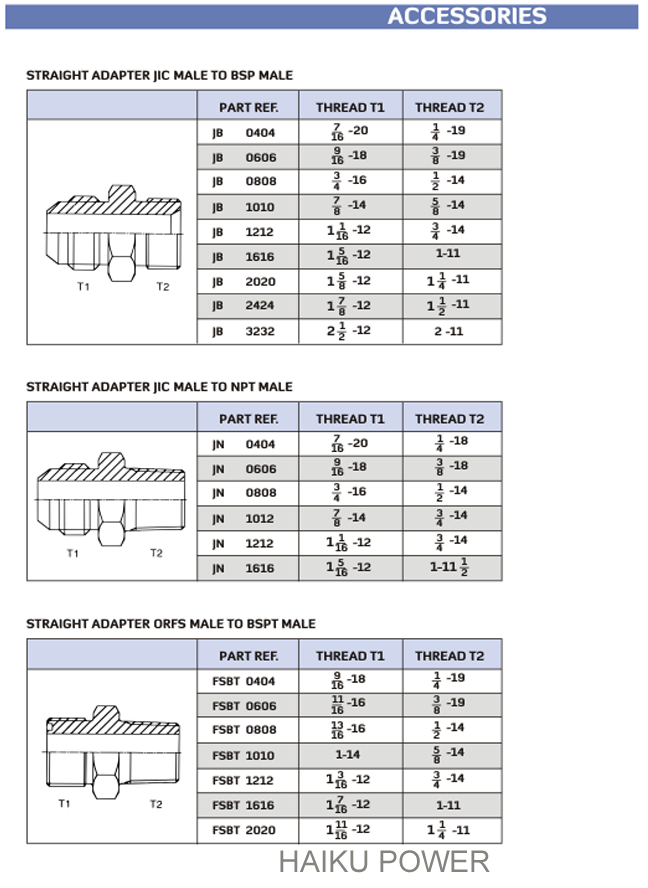

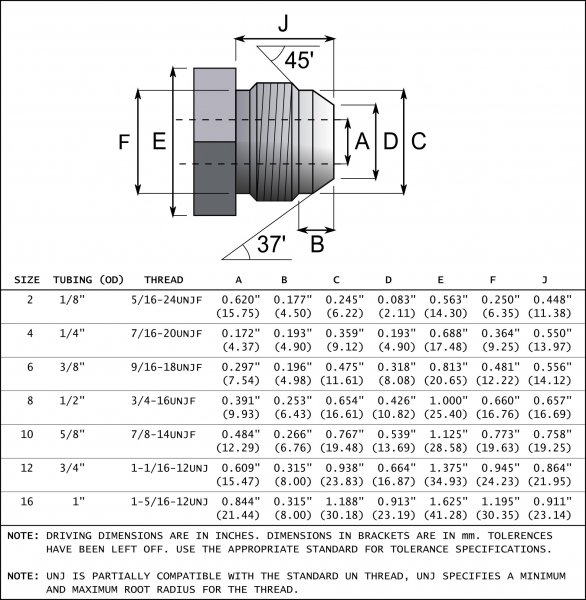

Web the acronym jic stands for joint industry council, are compression fittings machined with a 37 degree flare seating surface and parallel threads. They are commonly manufactured in nickel alloys, brass, carbon & stainless steel. Web the names an fittings, jic fittings, sae/iso fittings are often used interchangeably, despite that these cover three vastly different fitting types. Since these ttings don’t rely on mechanical deformation to create a seal, the risk of a broken tting or port is virtually eliminated. To get an accurate value, ensure that the thread pitch gauge is fitting well on the threads.

Both of these provide a highly reliable, reusable connection. In this article we cover jic pipe fittings, commonly known as sae/iso 37° flare fittings. Web the acronym jic stands for joint industry council, are compression fittings machined with a 37 degree flare seating surface and parallel threads. They are commonly manufactured in nickel alloys, brass, carbon & stainless steel. Web the names an fittings, jic fittings, sae/iso fittings are often used interchangeably, despite that these cover three vastly different fitting types.

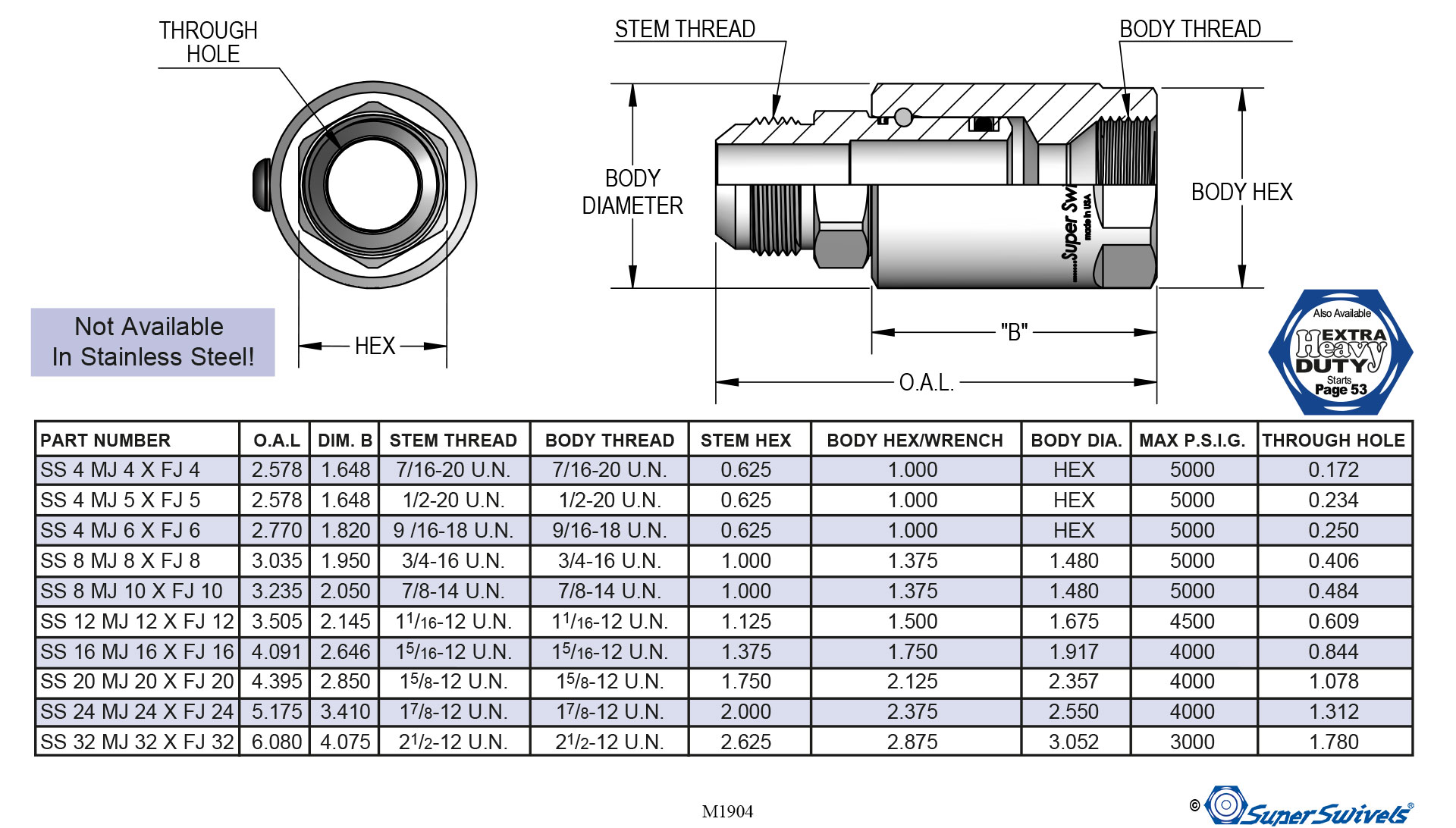

In this article we cover jic pipe fittings, commonly known as sae/iso 37° flare fittings. To get an accurate value, ensure that the thread pitch gauge is fitting well on the threads. The chart includes the thread o.d., thread. Web the acronym jic stands for joint industry council, are compression fittings machined with a 37 degree flare seating surface and parallel threads. They are commonly manufactured in nickel alloys, brass, carbon & stainless steel.

In this article we cover jic pipe fittings, commonly known as sae/iso 37° flare fittings. To get an accurate value, ensure that the thread pitch gauge is fitting well on the threads. Both of these provide a highly reliable, reusable connection. The chart includes the thread o.d., thread. Web the acronym jic stands for joint industry council, are compression fittings machined with a 37 degree flare seating surface and parallel threads. Since these ttings don’t rely on mechanical deformation to create a seal, the risk of a broken tting or port is virtually eliminated. They are commonly manufactured in nickel alloys, brass, carbon & stainless steel. Record the values and compare your measurements with the figures provided in this guide. Web the names an fittings, jic fittings, sae/iso fittings are often used interchangeably, despite that these cover three vastly different fitting types.

They Are Commonly Manufactured In Nickel Alloys, Brass, Carbon & Stainless Steel.

Record the values and compare your measurements with the figures provided in this guide. In this article we cover jic pipe fittings, commonly known as sae/iso 37° flare fittings. Since these ttings don’t rely on mechanical deformation to create a seal, the risk of a broken tting or port is virtually eliminated. To get an accurate value, ensure that the thread pitch gauge is fitting well on the threads.

The Chart Includes The Thread O.d., Thread.

Web the names an fittings, jic fittings, sae/iso fittings are often used interchangeably, despite that these cover three vastly different fitting types. Both of these provide a highly reliable, reusable connection. Web the acronym jic stands for joint industry council, are compression fittings machined with a 37 degree flare seating surface and parallel threads.