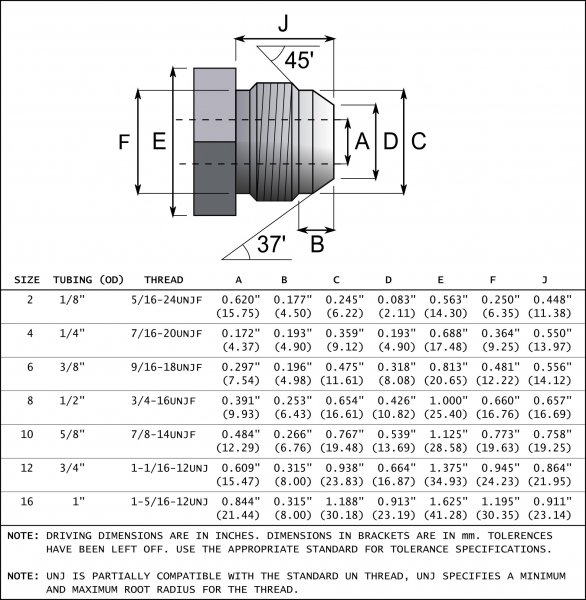

Web refer to this thread size chart, and ensure accurate measurement of jic fittings by comparing the thread o.d., thread i.d., and jic flare measurements for each fitting type. Use a thread pitch gauge to determine the number of threads per inch or the distance between threads in metric connections. Web fittings are available in two categories: Since these ttings don’t rely on mechanical deformation to create a seal, the risk of a broken tting or port is virtually eliminated. Both of these provide a highly reliable, reusable connection.

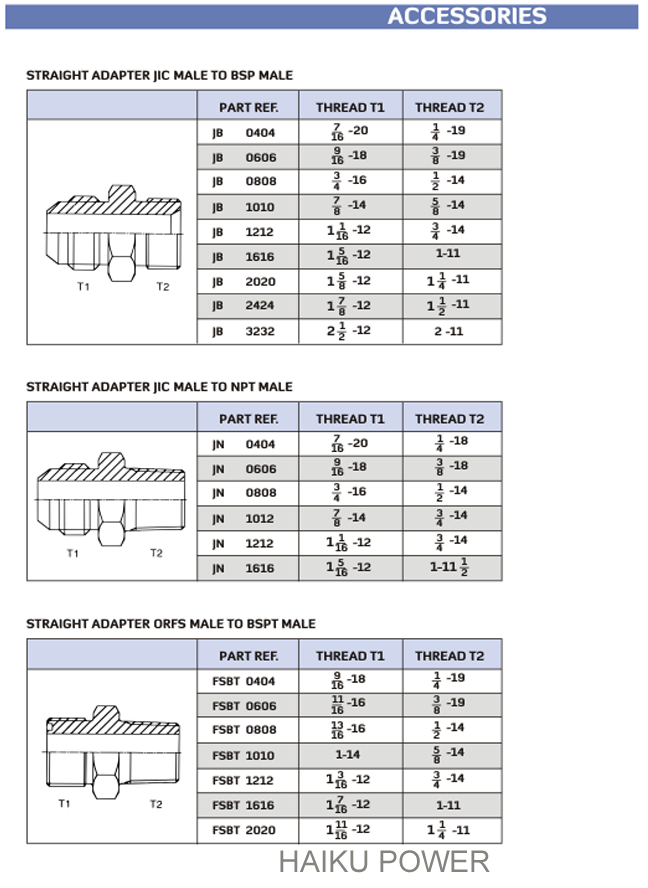

The names an fittings, jic fittings, sae/iso fittings are often used interchangeably, despite that these cover three vastly different fitting types. The acronym jic stands for joint industry council, are compression fittings machined with a 37 degree flare seating surface and parallel threads. Use a thread pitch gauge to determine the number of threads per inch or the distance between threads in metric connections. Din 2353 l (light) and din 2353 s (heavy) classes. By forcing the flare against the cone during the torquing process, the nose cone is slightly deformed and

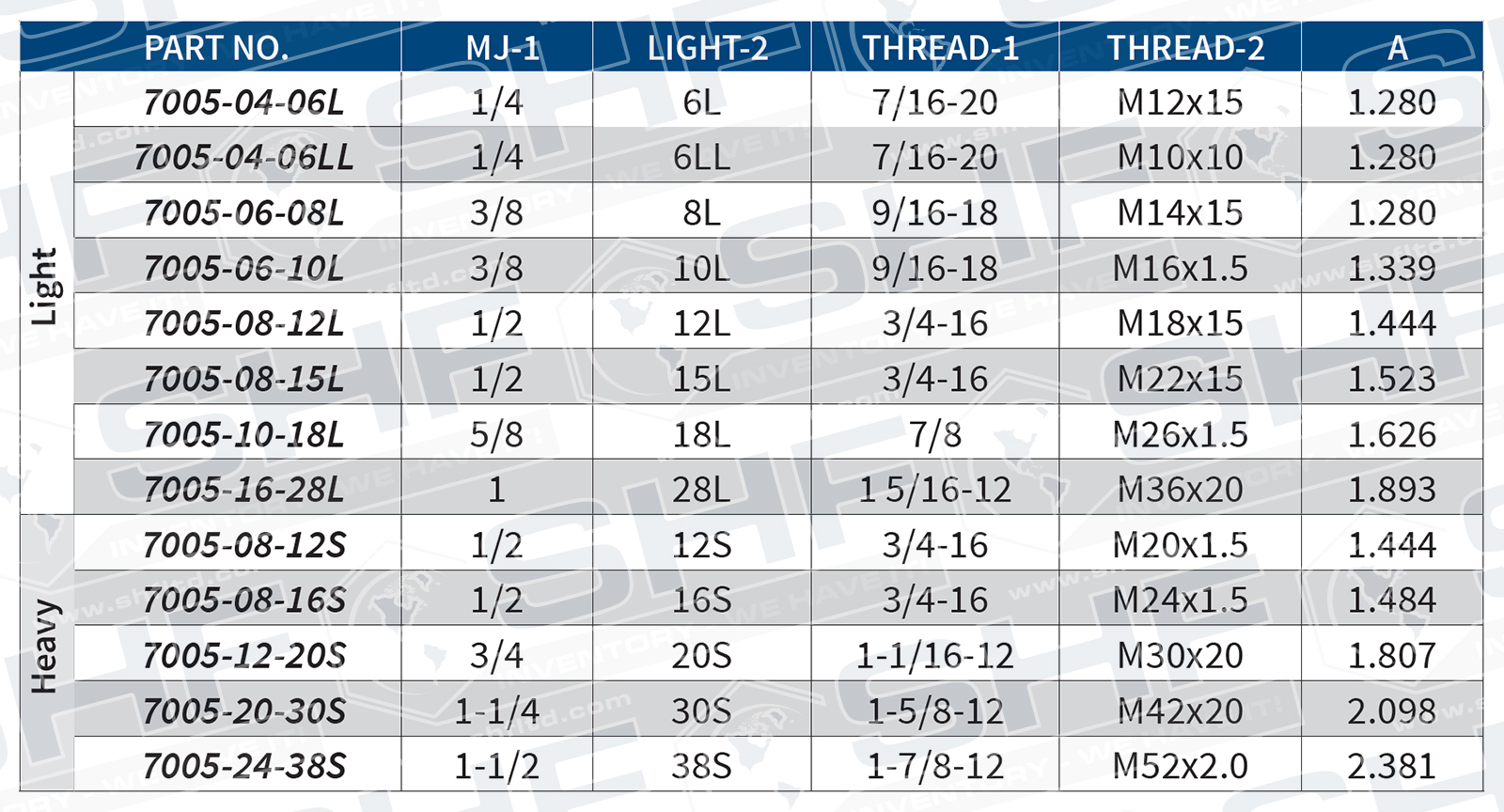

Din 2353 l (light) and din 2353 s (heavy) classes. Each has its own tube sizes and thread dimensions as shown in the following table: The acronym jic stands for joint industry council, are compression fittings machined with a 37 degree flare seating surface and parallel threads. Web in this article we cover jic pipe fittings, commonly known as sae/iso 37° flare fittings. Both of these provide a highly reliable, reusable connection.

Web measure the thread diameter with an i.d./o.d. Since these ttings don’t rely on mechanical deformation to create a seal, the risk of a broken tting or port is virtually eliminated. Each has its own tube sizes and thread dimensions as shown in the following table: By forcing the flare against the cone during the torquing process, the nose cone is slightly deformed and Use a thread pitch gauge to determine the number of threads per inch or the distance between threads in metric connections. Web fittings are available in two categories: Web jic adapter specifications male flared fittings include a conical nose with external threads for clamping. The acronym jic stands for joint industry council, are compression fittings machined with a 37 degree flare seating surface and parallel threads. A flared fitting or tube assembly is tightened against the cone with a swivel nut. Web refer to this thread size chart, and ensure accurate measurement of jic fittings by comparing the thread o.d., thread i.d., and jic flare measurements for each fitting type. Both of these provide a highly reliable, reusable connection. Din 2353 l (light) and din 2353 s (heavy) classes. Web in this article we cover jic pipe fittings, commonly known as sae/iso 37° flare fittings. Place the gauge on the threads until the fit is snug. The names an fittings, jic fittings, sae/iso fittings are often used interchangeably, despite that these cover three vastly different fitting types.

Din 2353 L (Light) And Din 2353 S (Heavy) Classes.

By forcing the flare against the cone during the torquing process, the nose cone is slightly deformed and Web in this article we cover jic pipe fittings, commonly known as sae/iso 37° flare fittings. Web fittings are available in two categories: Each has its own tube sizes and thread dimensions as shown in the following table:

The Names An Fittings, Jic Fittings, Sae/Iso Fittings Are Often Used Interchangeably, Despite That These Cover Three Vastly Different Fitting Types.

A flared fitting or tube assembly is tightened against the cone with a swivel nut. Both of these provide a highly reliable, reusable connection. Web measure the thread diameter with an i.d./o.d. Place the gauge on the threads until the fit is snug.

Web Refer To This Thread Size Chart, And Ensure Accurate Measurement Of Jic Fittings By Comparing The Thread O.d., Thread I.d., And Jic Flare Measurements For Each Fitting Type.

Web jic adapter specifications male flared fittings include a conical nose with external threads for clamping. The acronym jic stands for joint industry council, are compression fittings machined with a 37 degree flare seating surface and parallel threads. Since these ttings don’t rely on mechanical deformation to create a seal, the risk of a broken tting or port is virtually eliminated. Use a thread pitch gauge to determine the number of threads per inch or the distance between threads in metric connections.