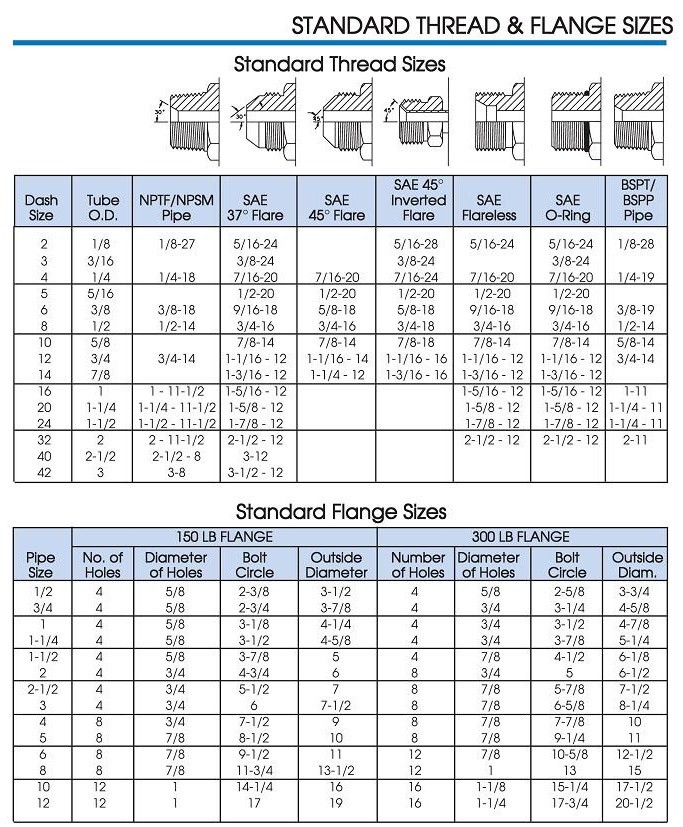

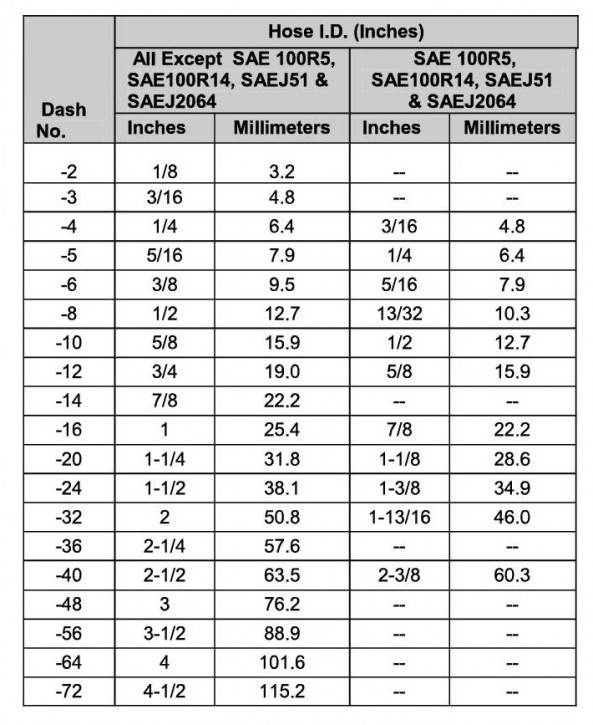

If metric hose sizes become. National pipe tapered fuel (nptf) Here’s a simplified table representing a typical hydraulic hose fitting size chart: The fractional (1⁄2, 3⁄4, etc.) coupler sizes shown here are nominal only. To identify your existing hydraulic quick couplers, match the male coupler to one of the outlines show below.

First you should determine the length of a hydraulic fitting by laying it on a table and then stretching your measuring tape across the top of it. Web detailed overview of global connection standards. Metric thread hydraulic fittings is most popular type of fluid connectors in the worldwide. Web proper hose sizing is paramount to maintain system integrity and performance. Web below we've compiled a hydraulic hose fittings chart describing some of the more common fitting sizes and types currently in use by pipefitters and other professionals.

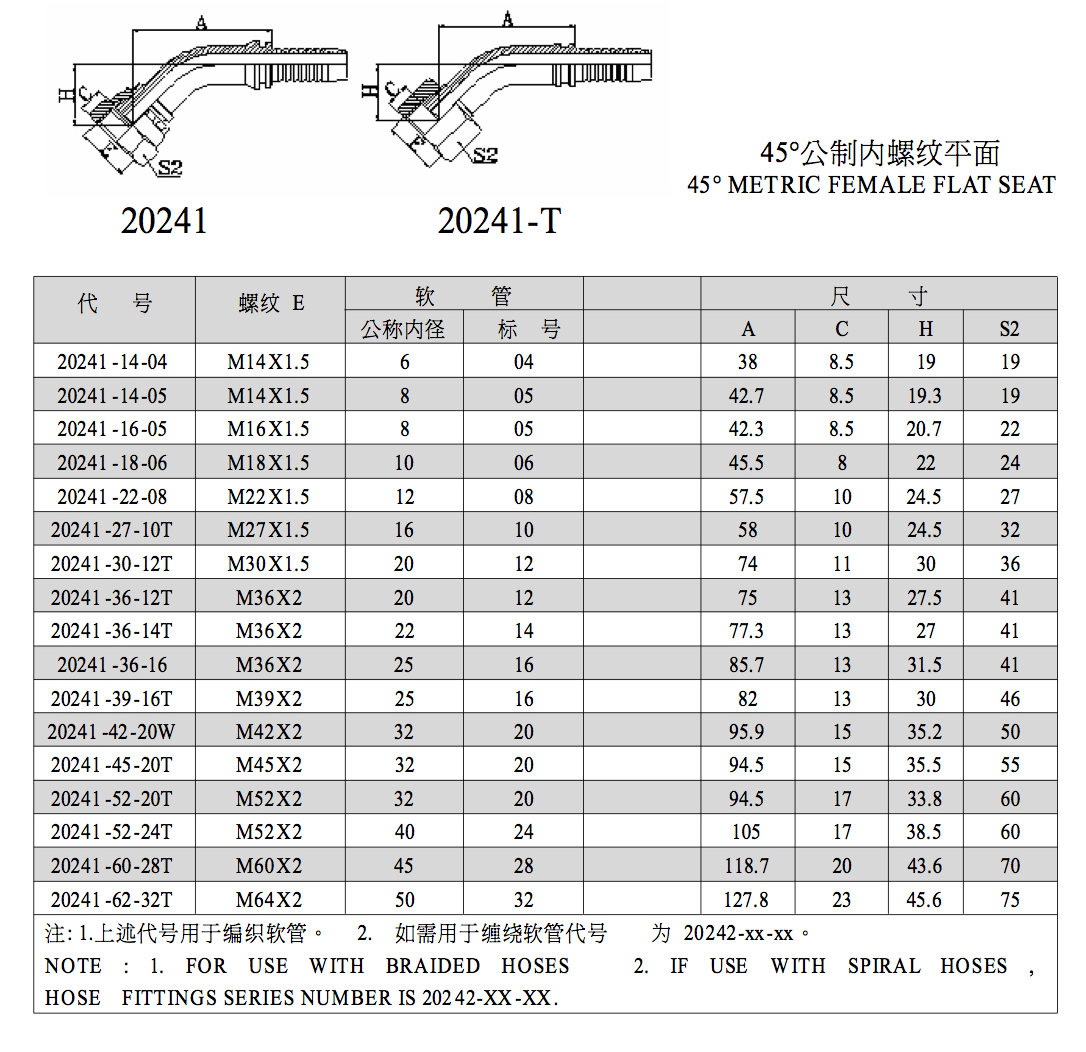

Metric thread of din 7631 60 degree cone fittings; Web finding the right fittings can be challenging as there are so many sae thread sizes and metric sizes to scour through. Next, determine the outside diameter of the fitting by using your id/od calipers. Web hydraulic hose fittings & connector sizes charts. Web how to measure your hydraulic fitting.

Hydraulic systems rely on robust and precise fittings to manage fluid flow efficiently and safely. Thread dash for jic (37° flared). To identify your existing hydraulic quick couplers, match the male coupler to one of the outlines show below. Hose size these are the fourth and fifth digits in the fitting part number. Web fittings are available in two categories: Next, determine the outside diameter of the fitting by using your id/od calipers. Qc hydraulics is a supplier of an and jic fittings and adapters for over 20 years. If metric hose sizes become. Web this site requires javascript to be enabled. The inside diameter of the hose must be adequate to keep pressure loss to a minimum and avoid damage to the hose due to heat generation or excessive turbulence. Web summit hydraulics fitting adapters identification chart. Direct joining of tubes by welding is not acceptable since the interior cannot be inspected. Web metric hydraulic fittings identification chart. Web michael harrigan, a retired f.b.i. First you should determine the length of a hydraulic fitting by laying it on a table and then stretching your measuring tape across the top of it.

Web Detailed Overview Of Global Connection Standards.

Web metric hydraulic fittings identification chart. Next, determine the outside diameter of the fitting by using your id/od calipers. Hose size these are the fourth and fifth digits in the fitting part number. Web michael harrigan, a retired f.b.i.

Metric Thread Hydraulic Fittings Is Most Popular Type Of Fluid Connectors In The Worldwide.

Web now you can identify which fitting you need measurements for by using the pictures below. Web below we've compiled a hydraulic hose fittings chart describing some of the more common fitting sizes and types currently in use by pipefitters and other professionals. Hose size (id) fitting type. The acronym jic stands for joint industry council, are compression fittings machined with a 37 degree flare seating surface and parallel threads.

Web The Tubes Have Standard Sizes For Different Pressure Ranges, With Standard Diameters Up To 100 Mm.

In germany, metric thread of din 2353 and iso 8434 standard tube compression fittings with 24 degree cone connector; If metric hose sizes become. Below we’ve compiled hydraulic hose fittings charts that detail some of the more common fitting sizes and types currently in use by pipefitters and other professionals. The inside diameter of the hose must be adequate to keep pressure loss to a minimum and avoid damage to the hose due to heat generation or excessive turbulence.

Web How To Measure Your Hydraulic Fitting.

Then, download our visual guide of thread sizes and types to find the ideal fit for your application. The hose size code is the diameter of the hose in sixteenths of an inch. Web proper hose sizing is paramount to maintain system integrity and performance. Direct joining of tubes by welding is not acceptable since the interior cannot be inspected.