Web follow requirements in osha 1910.252 (a) (2) (iv) and nfpa 51b for hot work and have a fire watcher and extinguisher nearby. These settings determine the heat, wire deposition rate, and. Web find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. After you have determined the thickness and type of material, selected a proper shielding gas and electrode, and. This article presents guidelines that can help you identify which parameters to.

Read and understand the safety data sheets. Web follow requirements in osha 1910.252 (a) (2) (iv) and nfpa 51b for hot work and have a fire watcher and extinguisher nearby. Web the most important mig welder settings are voltage, wire feed speed, and shielding gas flow rate. These settings determine the heat, wire deposition rate, and. Web download the app version of the weld setting calculator for easy reference!

These settings determine the heat, wire deposition rate, and. If not, perhaps your parameters need tweaking. Web are you producing quality weld beads? Web find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. Web download the app version of the weld setting calculator for easy reference!

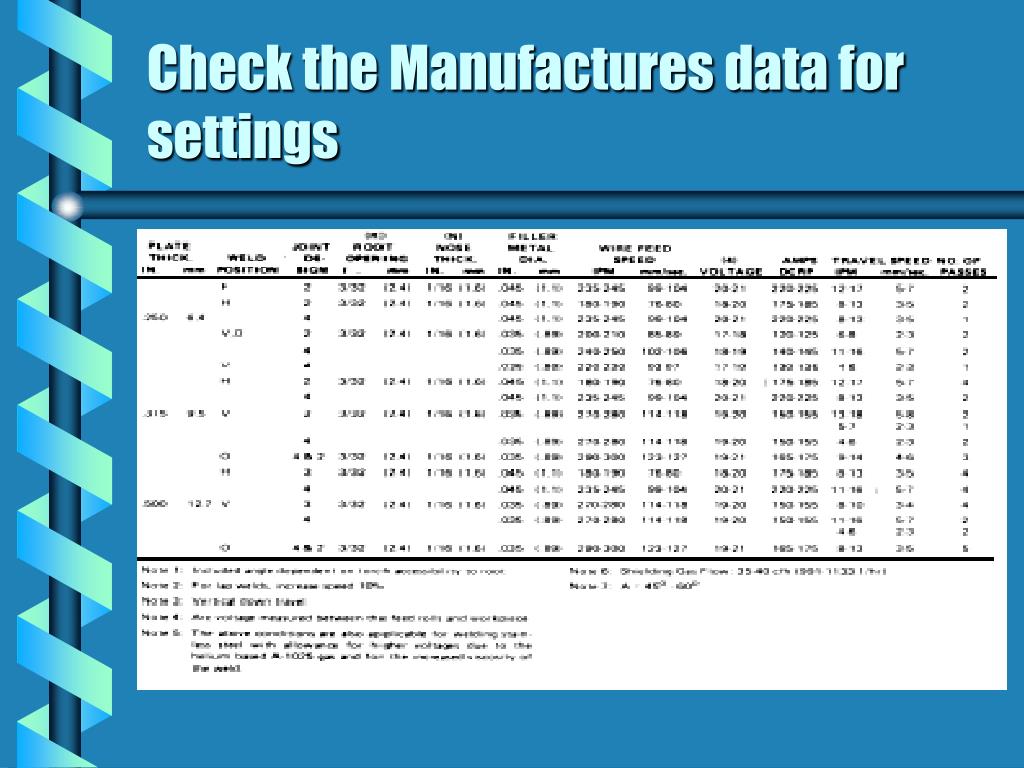

These settings determine the heat, wire deposition rate, and. Web download the app version of the weld setting calculator for easy reference! Wire speed controls amperage as well as the amount of weld penetration. Web follow requirements in osha 1910.252 (a) (2) (iv) and nfpa 51b for hot work and have a fire watcher and extinguisher nearby. Web the most important mig welder settings are voltage, wire feed speed, and shielding gas flow rate. Read and understand the safety data sheets. If not, perhaps your parameters need tweaking. Web set the wire feed speed. Web take a look at the chart below for some starting settings: This article presents guidelines that can help you identify which parameters to. Web are you producing quality weld beads? After you have determined the thickness and type of material, selected a proper shielding gas and electrode, and. Web mig welding settings: Web find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal.

After You Have Determined The Thickness And Type Of Material, Selected A Proper Shielding Gas And Electrode, And.

Web mig welding settings: Read and understand the safety data sheets. This article presents guidelines that can help you identify which parameters to. These settings determine the heat, wire deposition rate, and.

Web Are You Producing Quality Weld Beads?

Web take a look at the chart below for some starting settings: Web follow requirements in osha 1910.252 (a) (2) (iv) and nfpa 51b for hot work and have a fire watcher and extinguisher nearby. Web download the app version of the weld setting calculator for easy reference! Web set the wire feed speed.

If Not, Perhaps Your Parameters Need Tweaking.

Wire speed controls amperage as well as the amount of weld penetration. Web the most important mig welder settings are voltage, wire feed speed, and shielding gas flow rate. Web find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal.