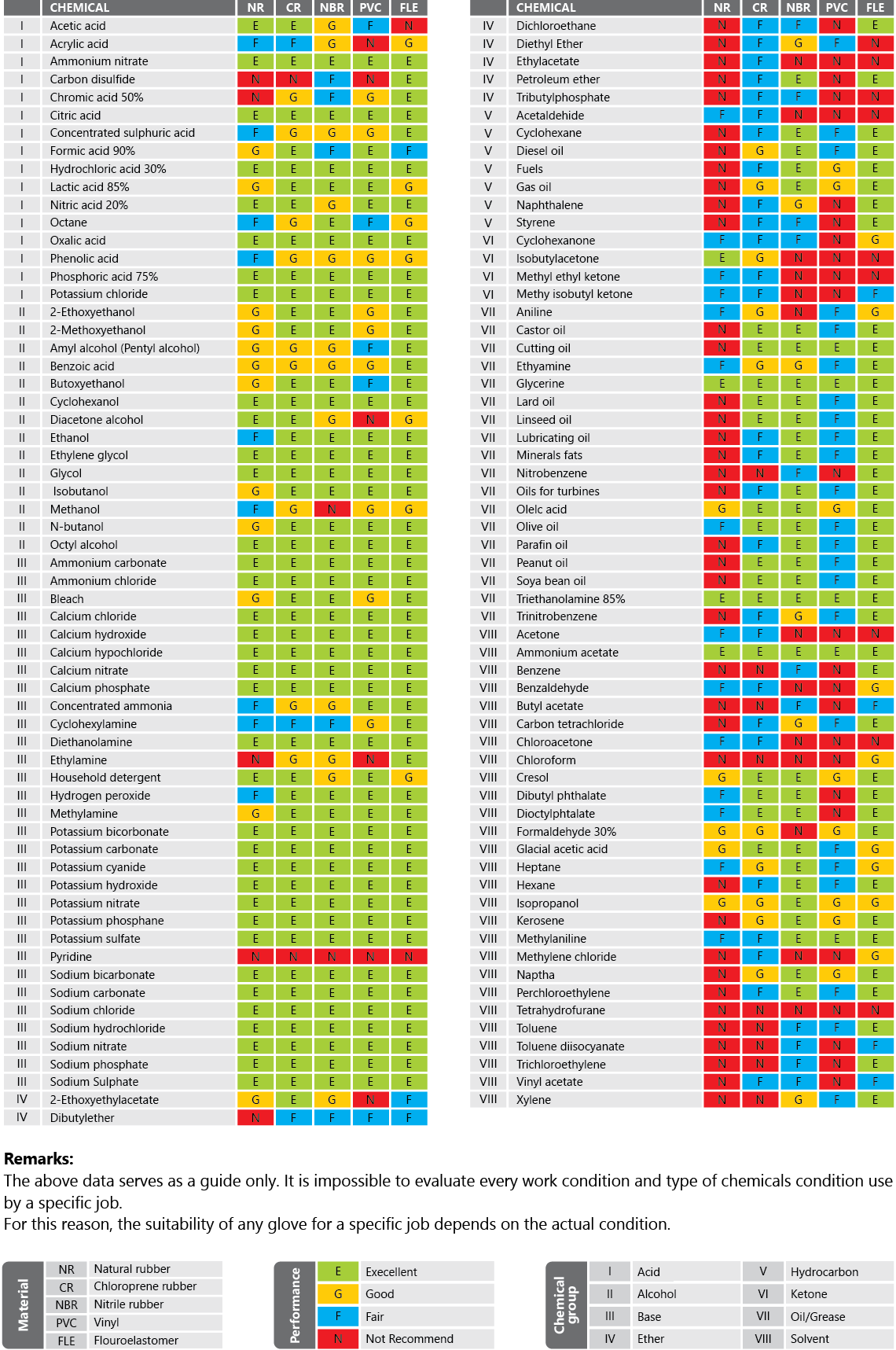

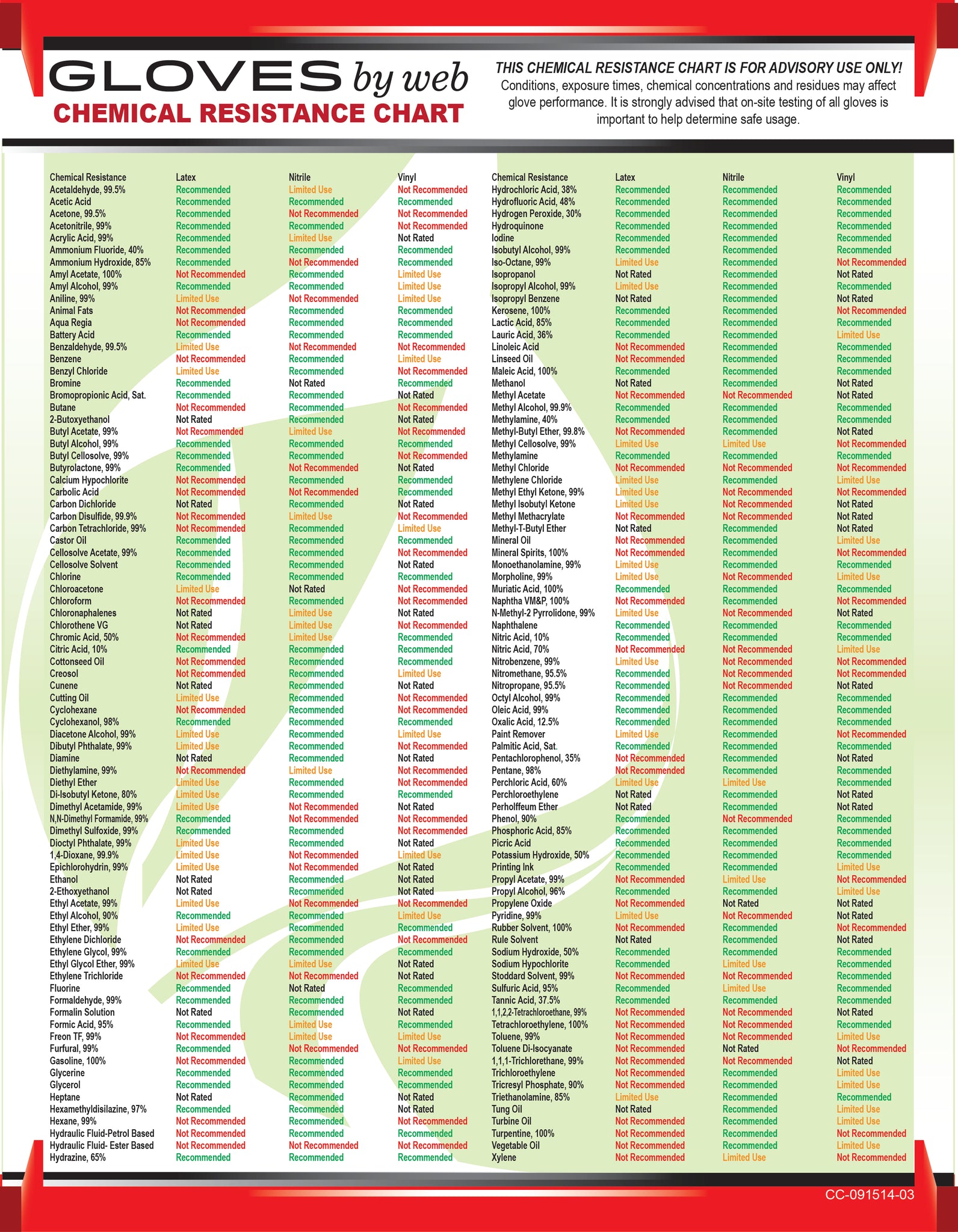

Web vwr glove chemical resistance chart. The ratings are abbreviated as follows: Natural, butyl, neoprene, nitrile and fluorocarbon (viton); Web this chemical resistance chart is intended to provide general information about the reactions of different glove materials to the chemicals listed. No one type of glove will protect against all chemical hazards.

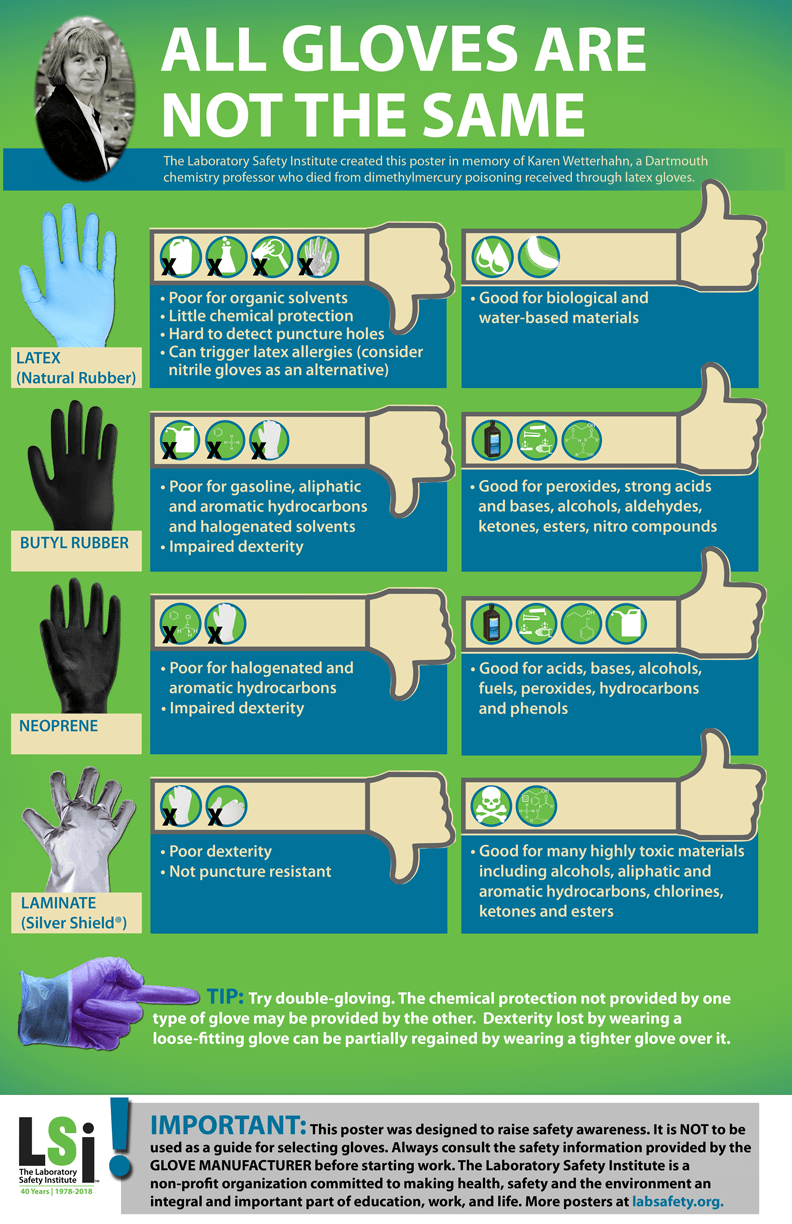

1 if you are allergic to natural rubber products, you may double glove with 8 mil nitrile gloves. If a chemical has a significant impact on the physical properties of a glove material, its permeation resistance is quickly impaired. Web the data presented here is from the most currently published compilation of chemical resistance data from numerous manufacturers of chemical protective clothing. Web general advisory information for broadly recognized chemical resistance characteristics of gloves to a given chemical agent. The data outlined here is taken from the sixth edition of quick selection guide to chemical protective clothing by forsberg et al.

Web the following table from the u.s. Web general advisory information for broadly recognized chemical resistance characteristics of gloves to a given chemical agent. Web osha glove selection chart. The most obvious forms of degradation are the loss of the glove’s strength and excessive swelling. Natural, butyl, neoprene, nitrile and fluorocarbon (viton);

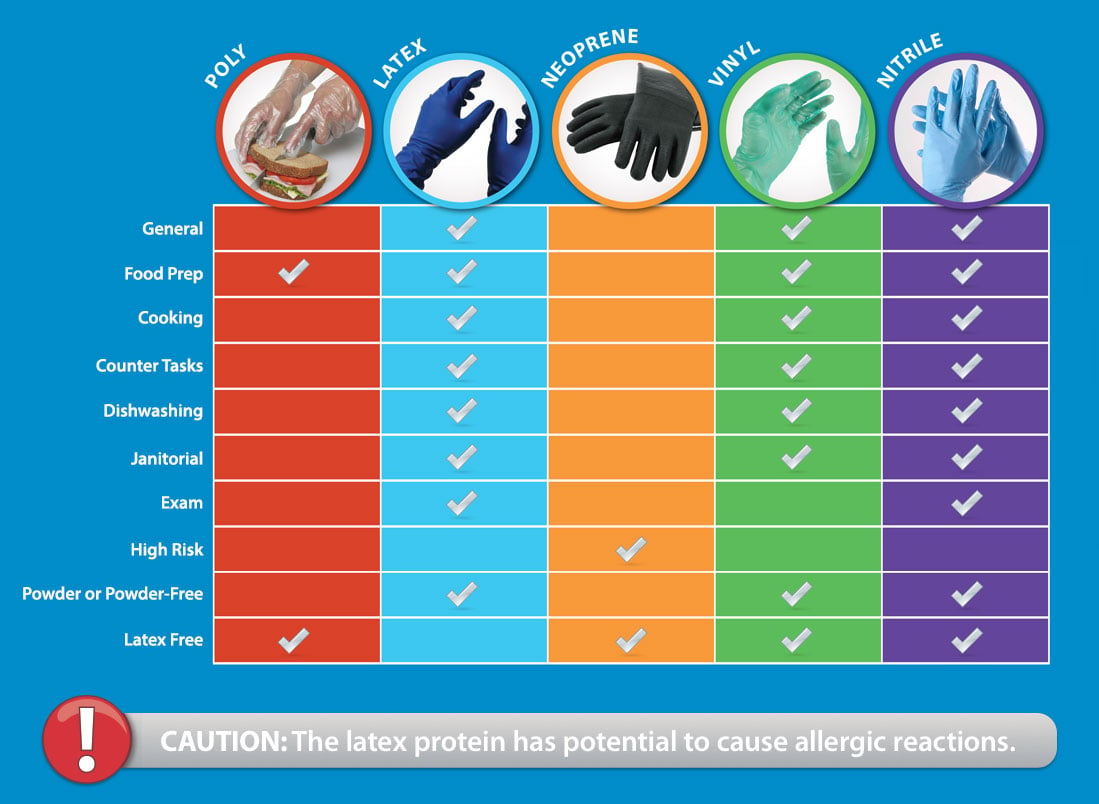

The most obvious forms of degradation are the loss of the glove’s strength and excessive swelling. Not all gloves have been tested against each chemical, therefore the chart should be used to provide basic guidance on resistances by material. This general resistance chart is available as a guide only. Web general advisory information for broadly recognized chemical resistance characteristics of gloves to a given chemical agent. Take into account the degree of dexterity required. 1 if you are allergic to natural rubber products, you may double glove with 8 mil nitrile gloves. Web this chemical resistance guide incorporates three types of information: Web the data presented here is from the most currently published compilation of chemical resistance data from numerous manufacturers of chemical protective clothing. The data outlined here is taken from the sixth edition of quick selection guide to chemical protective clothing by forsberg et al. It is important to conduct a risk assessment prior to the selection of any gloves. Web the following table from the u.s. • degradation (d)is a deleterious change in one or more of the glove’s physical properties. Web certain glove materials may become hard, stiff, or brittle, or they may grow softer, weaker, and swell to several times their original size. The ratings are abbreviated as follows: Web osha glove selection chart.

It Is Important To Conduct A Risk Assessment Prior To The Selection Of Any Gloves.

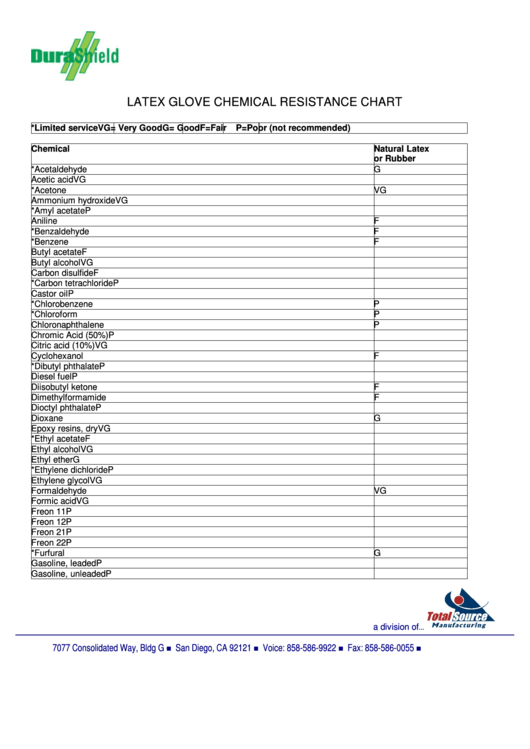

Not all gloves have been tested against each chemical, therefore the chart should be used to provide basic guidance on resistances by material. The ratings are abbreviated as follows: Web osha glove selection chart. Web this chemical resistance chart is intended to provide general information about the reactions of different glove materials to the chemicals listed.

Web Esko Glove Chemical Resistance Chart.

Web the following table from the u.s. Polyvinyl chloride (pvc), polyvinyl alcohol and polyethylene. Or various kinds of plastic: Department of energy (occupational safety and health technical reference manual) rates various gloves as being protective against specific chemicals and will help you select the most appropriate gloves to protect your employees.

If A Chemical Has A Significant Impact On The Physical Properties Of A Glove Material, Its Permeation Resistance Is Quickly Impaired.

The most obvious forms of degradation are the loss of the glove’s strength and excessive swelling. Take into account the degree of dexterity required. Web vwr glove chemical resistance chart. The chemical resistance ratings are based on published research data and the general information within in no way warrants the performance of any type of glove.

Sas Safety Gloves Have Not Been Individually Tested Against These Chemicals.

Several published degradation lists (primarily “the general chemical. Web certain glove materials may become hard, stiff, or brittle, or they may grow softer, weaker, and swell to several times their original size. • degradation (d)is a deleterious change in one or more of the glove’s physical properties. This general resistance chart is available as a guide only.