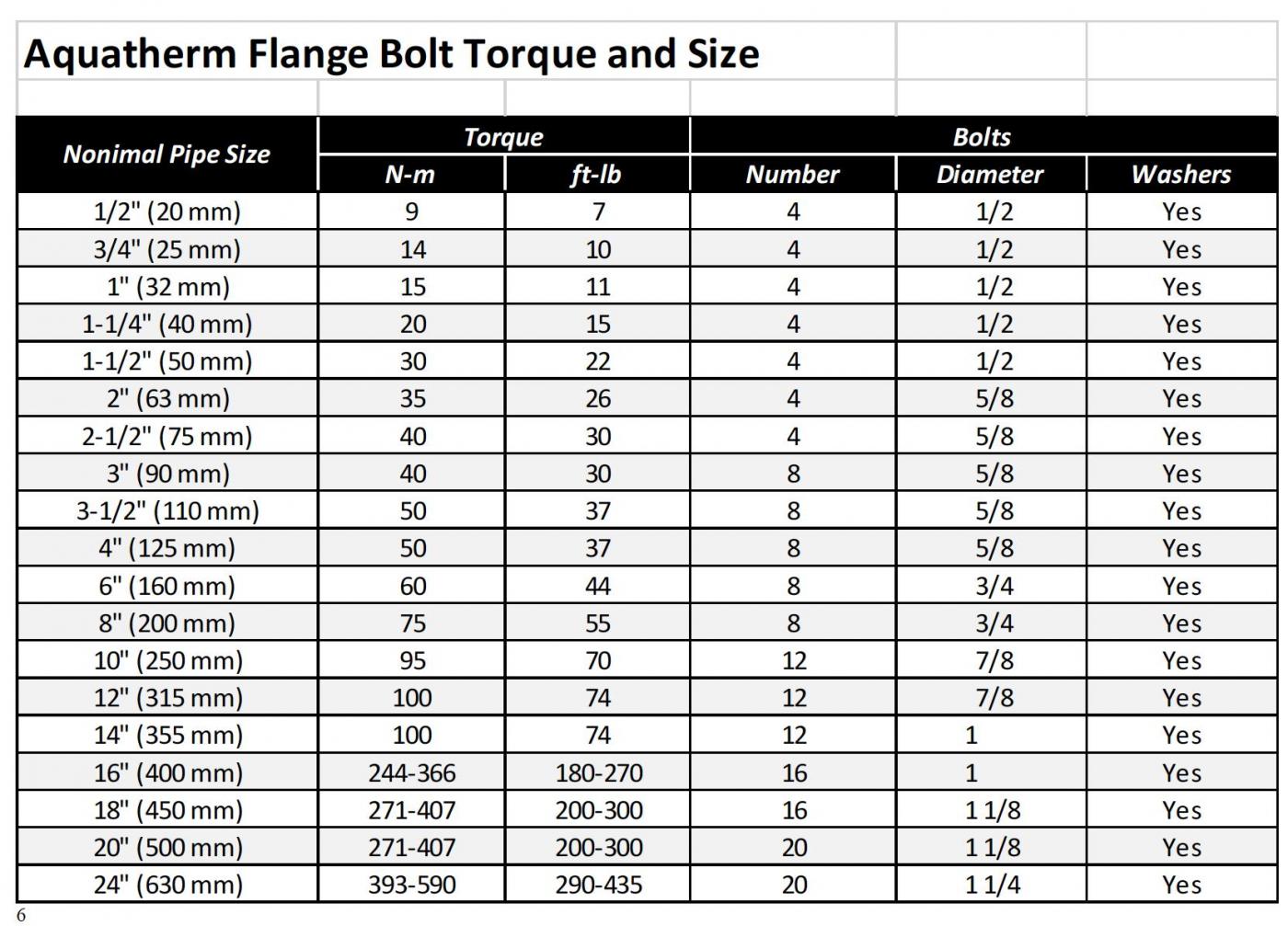

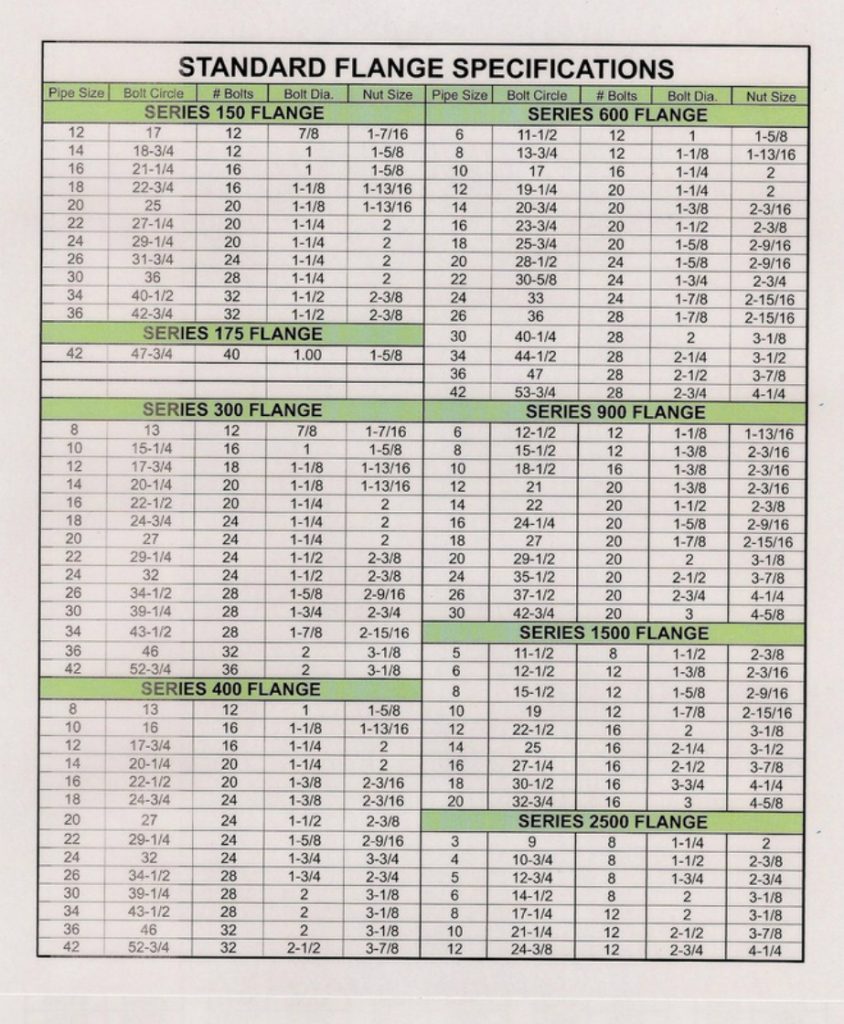

Find out the factors affecting the torque, the hot torq… Web find flange torque charts for different nominal pipe sizes (nps) and flange classes from 150 to 2500. Web a successful flange installation requires the proper amount of load applied to the gasket. Web class 2500 flange torque charts listed by nominal pipe size. Web these bolt torque values are intended for use as guidelines only and are based on ideal conditions, perfect flanges, flange alignment & new well lubricated bolts/nuts according.

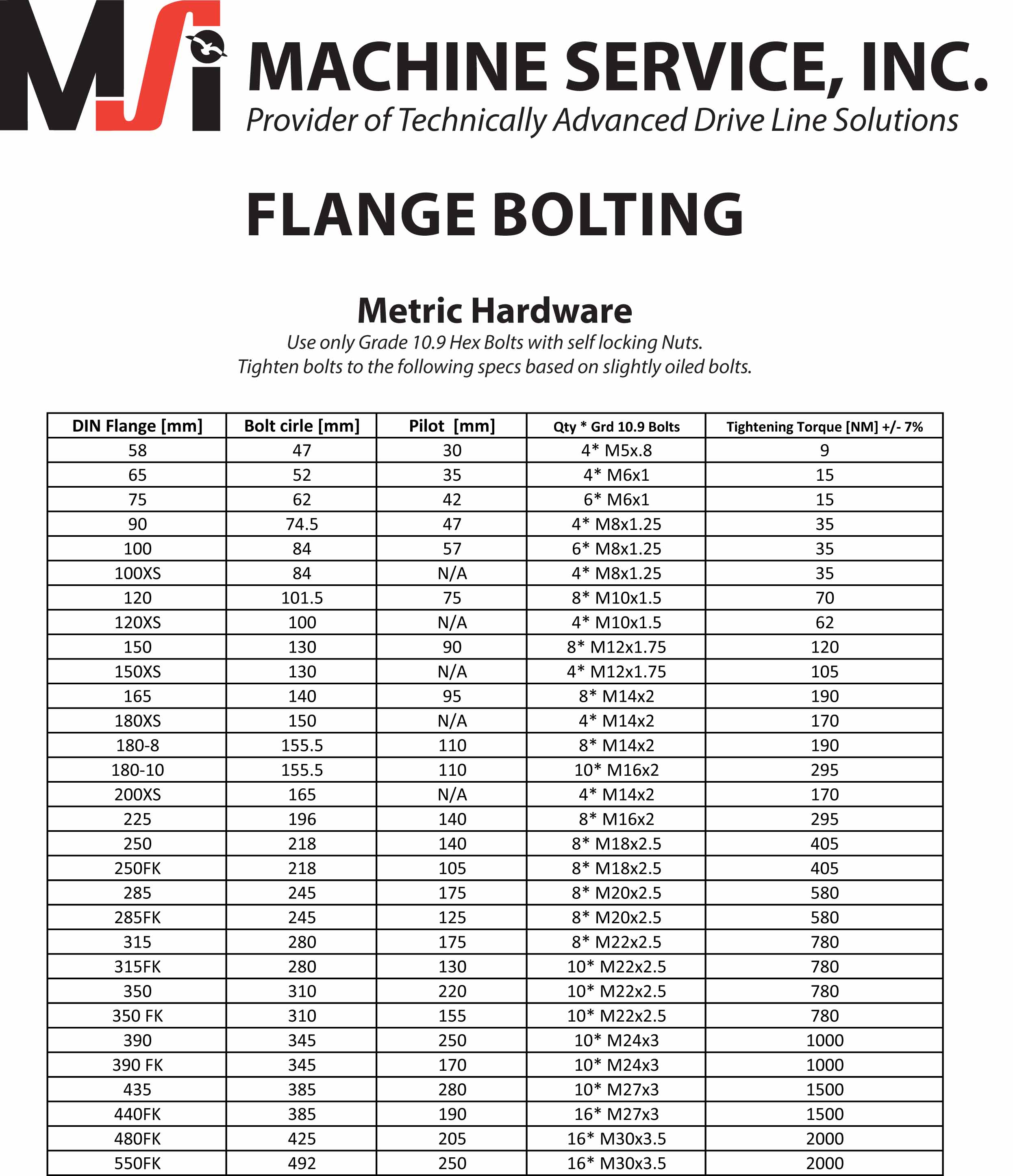

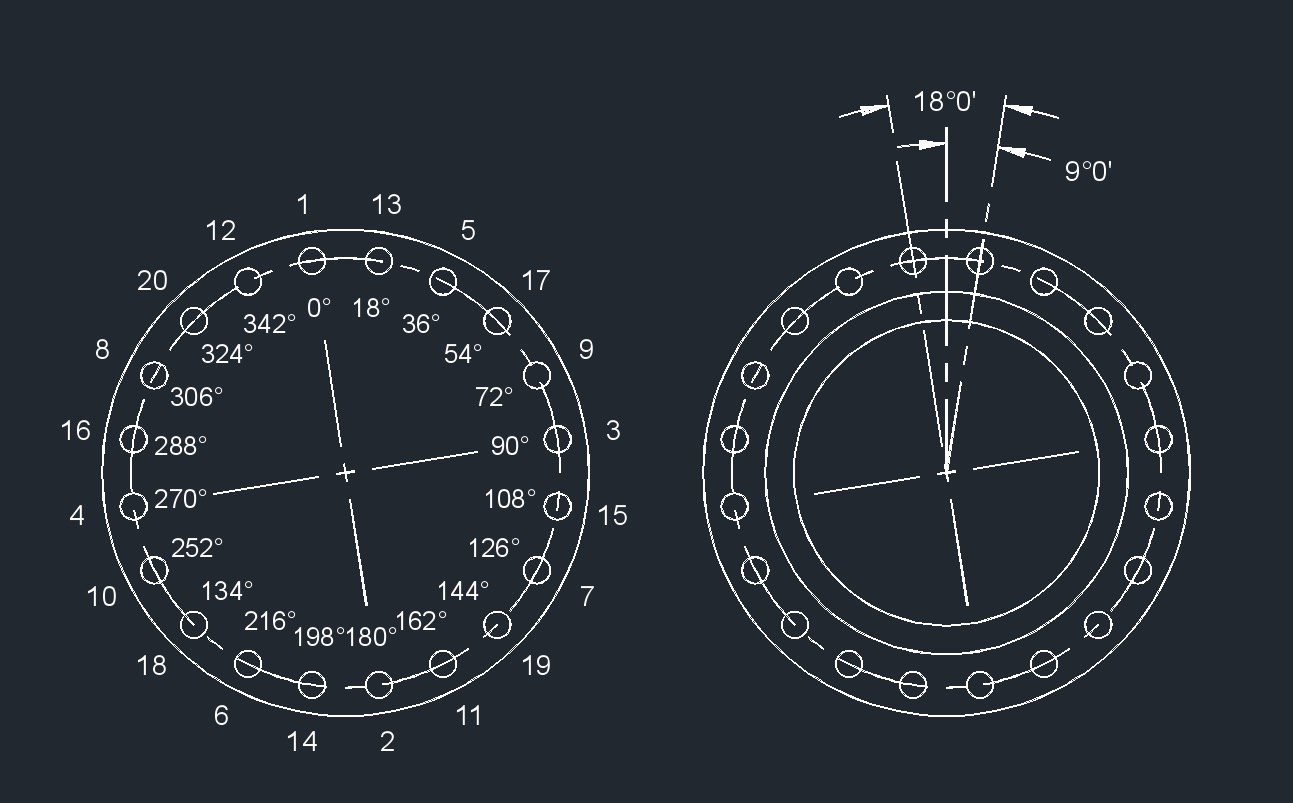

See tables for different pipe sizes, bolt sizes, and. Web ses 75% of the yield strength. Lookup bolt lengths, wrench sizes, and torque patters using the flange bolt app. Grade 2, 5, and 8 values are for. Recommended torque values lubricated stud bolts w/0.15 friction value.

Web class 2500 flange torque charts listed by nominal pipe size. Web class 600 flange torque charts listed by nominal pipe size. Find out the factors affecting the torque, the hot torq… Web these bolt torque values are intended for use as guidelines only and are based on ideal conditions, perfect flanges, flange alignment & new well lubricated bolts/nuts according. Web class 1500 flange torque charts listed by nominal pipe size.

Flange materials:astm a105, astm a182 grades f50 and f51, astm a350 grades lf2 and lf3, astm a694 grades f52 and f60. See tables for different pipe sizes, bolt sizes, and. Web find torque values for asme b16.47 and b16.5 flanges with a193 grade b7 bolts and homogenous elastomeric gaskets. Web these bolt torque values are intended for use as guidelines only and are based on ideal conditions, perfect flanges, flange alignment & new well lubricated bolts/nuts according. Web bolting torque to develop 50% bolt yield stress at nut factor, k=0.16. Grade 2, 5, and 8 values are for. Web class 2500 flange torque charts listed by nominal pipe size. Web class 600 flange torque charts listed by nominal pipe size. Lookup bolt lengths, wrench sizes, and torque patters using the flange bolt app. Web for most the accurate references in critical situations torque values should be replaced with field measured tension values. Learn how to calculate flange bolt torque using a formula and a chart for different types of gaskets and flanges. Web the flange bolt torque calculator simplifies the task of determining the correct torque for flange bolt tightening, helping to ensure the integrity and safety of critical connections in. The torque tables are built on specific assumptions regarding bolt and nut factor. Web flange bolt size chart and torque patterns. The conventional way to achieve that load is by applying a measured torque to the.

Web Key Charts For Stud Bolts:

Web class 600 flange torque charts listed by nominal pipe size. Web ansi 150# flanges ansi 300# flanges ansi 600# flanges. Web a successful flange installation requires the proper amount of load applied to the gasket. Lookup bolt lengths, wrench sizes, and torque patters using the flange bolt app.

Asme Flange Bolting (Number, Diameter, Length Of Stud Bolts By Asme Flange Sizes);

Web find flange torque charts for different nominal pipe sizes (nps) and flange classes from 150 to 2500. Flanges according to asme b16.5 norm. The conventional way to achieve that load is by applying a measured torque to the. Grade 2, 5, and 8 values are for.

Find Out The Factors Affecting The Torque, The Hot Torq…

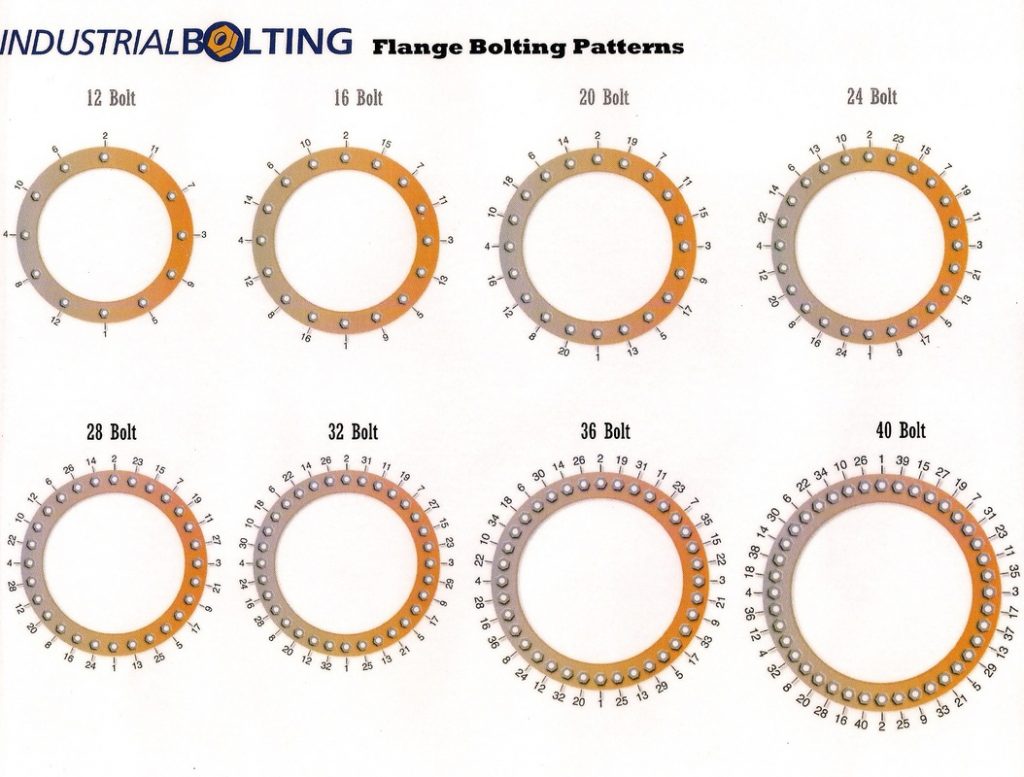

Click on the links to access the charts and download them as pdf files. Learn how to calculate flange bolt torque using a formula and a chart for different types of gaskets and flanges. Web welcome to this interactive flange bolting calculator from hytorc.the program computes recommended torque values , bolting patterns, tool selection and pump pressure. The prevailing torque lock nut clamp loads are listed at 75% of the proof loads specified for the appropriate grade bolt:

See Tables For Different Pipe Sizes, Bolt Sizes, And.

Web for most the accurate references in critical situations torque values should be replaced with field measured tension values. Web class 1500 flange torque charts listed by nominal pipe size. Before using a given torque table, these assumptions. The torque tables are built on specific assumptions regarding bolt and nut factor.