Step by step test instructions. Web learning how to check engine compression will give one the ability to check performance issues of your car and increase them if desired. Web an engine compression test is the most practical way to learn about the mechanical condition of your engine without the need to disassemble it. Begin with a normal (static) compression test on a warm engine to eliminate obvious problems such as badly worn rings, burnt or bent valves or holes in pistons. Web so, if your engine is running rough or is lacking power, consider doing a compression test.

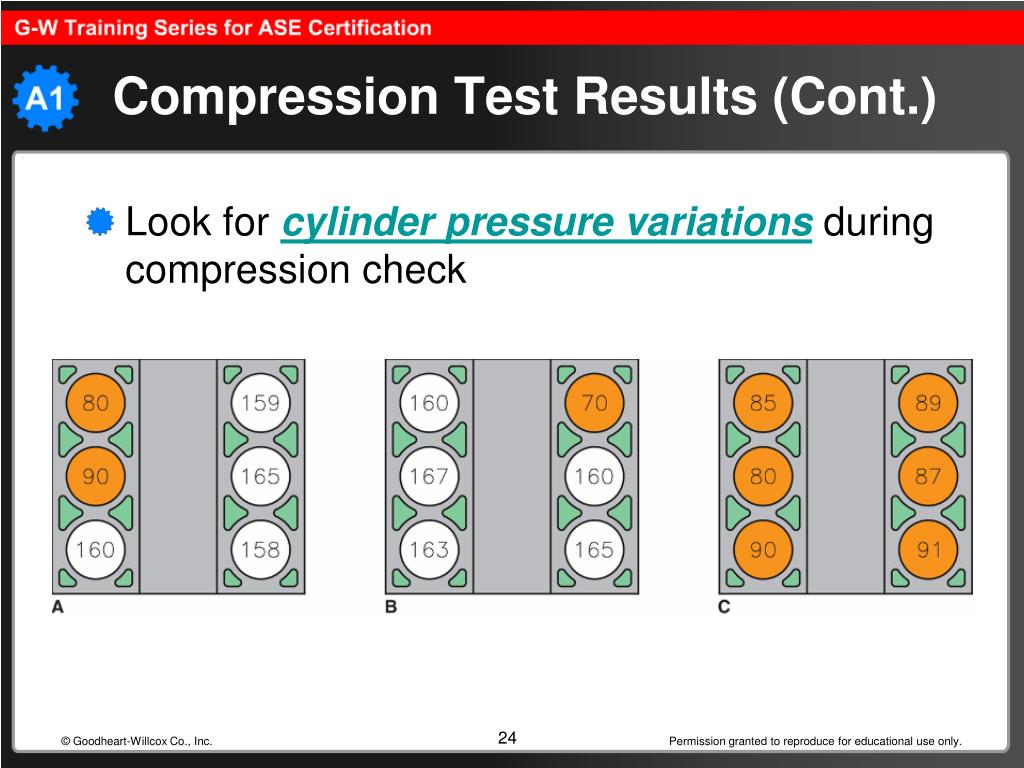

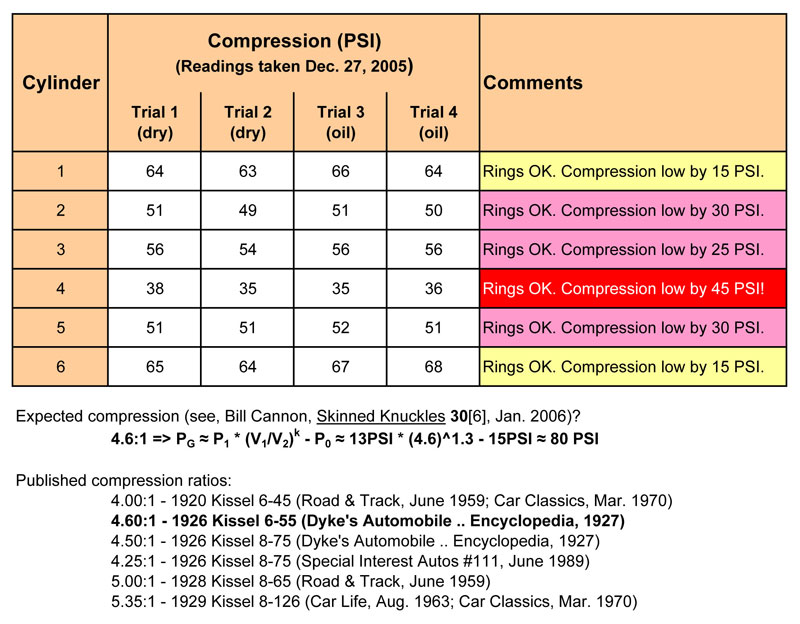

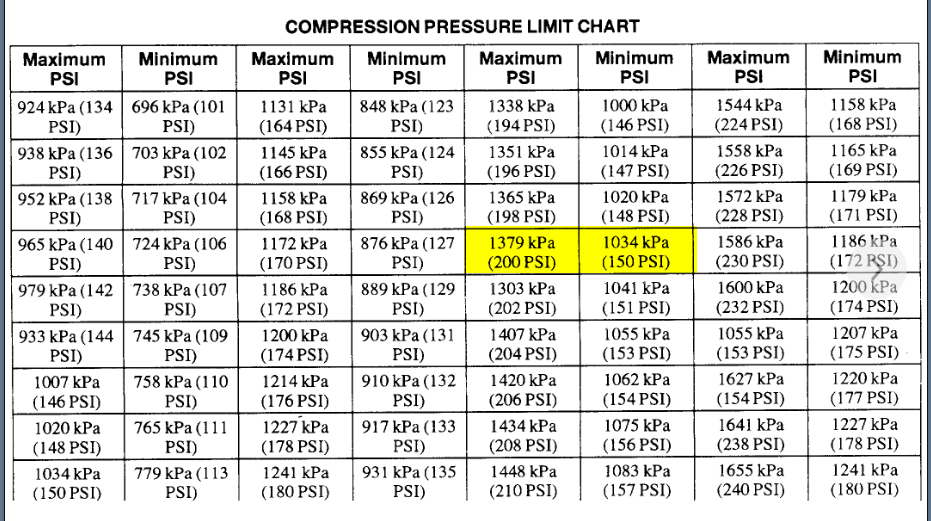

Web then, use this chart to record all the compression information, from the cranking (static), idle and snap tests. No cylinder should have a pressure lower than 75% of the highest recorded value. Begin with a normal (static) compression test on a warm engine to eliminate obvious problems such as badly worn rings, burnt or bent valves or holes in pistons. A leak down test result of 30 percent should not be a cause for alarm. Low engine compression can cause a misfire code.

Put the compression test adapter into the engine's first cylinder. Web a compression test is a decent way to assess the sealing functions of an engine’s valves and valve seats, piston rings and cylinder head gaskets. Specifically, parts like intake and exhaust valves, valve seats, head gaskets, and the piston rings are common parts that can wear out and lead to. Attach the gauge to each cylinder, ensuring a secure connection. Web a compression test is to determine how much pressure the engine makes, and a leakdown test measures its ability to hold pressure.

Most engines will have a compression ratio that exceeds 100 psi. Web then, use this chart to record all the compression information, from the cranking (static), idle and snap tests. Web to check your vehicle’s engine with a compression test, you need a compression gauge and safety gear. Low engine compression can cause a misfire code. Web create a chart similar to this example to record your test readings. Analysis of the current/voltage changes gives the comparative compression values of all cylinders. Attach the gauge to each cylinder, ensuring a secure connection. Web the pressure of each cylinder should be measured and compared to the values for each of the remaining engine cylinders. Web a compression test reveals the condition of your engine's valves, its valve seats, and piston rings and whether these parts are wearing evenly. Web an engine compression test is the most practical way to learn about the mechanical condition of your engine without the need to disassemble it. Web the premise of a compression test is to test each cylinder to see in measured psi exactly how much compression that particular cylinder is producing. Web by measuring the compression pressure generated within each cylinder, technicians can identify potential issues such as worn piston rings, leaking valves, or damaged cylinder walls, enabling them to address these problems promptly and restore optimal engine performance. In this video, we show you how to do it and how to interpret the results. Step by step test instructions. How to prepare for a compression test.

No Cylinder Should Have A Pressure Lower Than 75% Of The Highest Recorded Value.

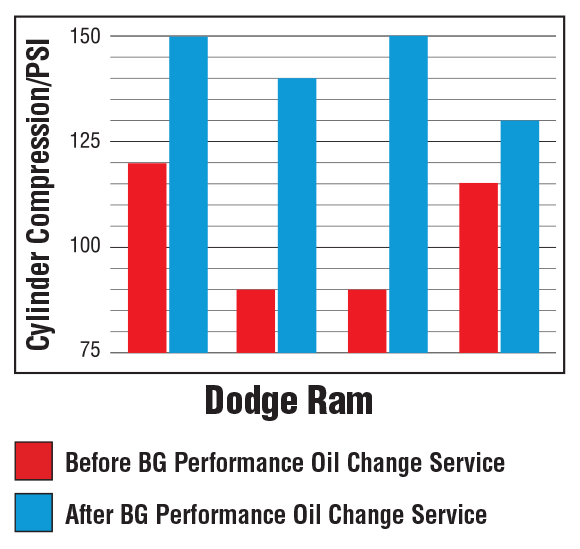

Web the principle of the relative compression test is based on tracking the battery current/voltage changes during cranking to determine the compression values of all cylinders. Analysis of the current/voltage changes gives the comparative compression values of all cylinders. Web testing engine compression provides a snapshot of the health of your engine. The test will help you locate potential internal problems affecting engine performance.

Web To Check Your Vehicle’s Engine With A Compression Test, You Need A Compression Gauge And Safety Gear.

Note the circular cylinders and the timing belt on the engine’s front. Web by measuring the compression pressure generated within each cylinder, technicians can identify potential issues such as worn piston rings, leaking valves, or damaged cylinder walls, enabling them to address these problems promptly and restore optimal engine performance. 705k views 7 years ago. Web regular engine misfires, reduced acceleration, and poor fuel economy are indicators that you need to conduct an engine compression test.

Web How To Do An Engine Compression Test On 3.0L And 3.8L V6 Equipped Ford, Mercury And Lincoln.

Web below is a guide on how to do a compression test and interpret the results. Begin with a normal (static) compression test on a warm engine to eliminate obvious problems such as badly worn rings, burnt or bent valves or holes in pistons. Web learning how to check engine compression will give one the ability to check performance issues of your car and increase them if desired. Start with a cranking (static) compression test on a warm engine, to cancel out obvious problems, such as:

Put The Compression Test Adapter Into The Engine's First Cylinder.

You need a fully charged battery when carrying out the test to get an accurate reading. Healthy engines should have compression. Web how to do a compression test on your engine. Attach the gauge to each cylinder, ensuring a secure connection.