When your wireless drill will produce the maximum volume, you will see a certain number with “hm”. Hammer rate (or blow rate): Understanding torque is crucial to achieving precision when working with materials of different densities. It’s important to use the correct torque setting to avoid damaging the material you are working with or stripping screws. The numbers are designed with a rotational clutch.

Setting 2 is a medium speed/torque and can be used for drilling or driving. Web we’ll explain how to adjust the torque or clutch settings on a drill and what the hammer settings on a cordless drill do. When your wireless drill will produce the maximum volume, you will see a certain number with “hm”. Set the clutch to the desired torque level. Web discover how to achieve optimal results by correctly utilizing drill torque settings in this comprehensive guide.

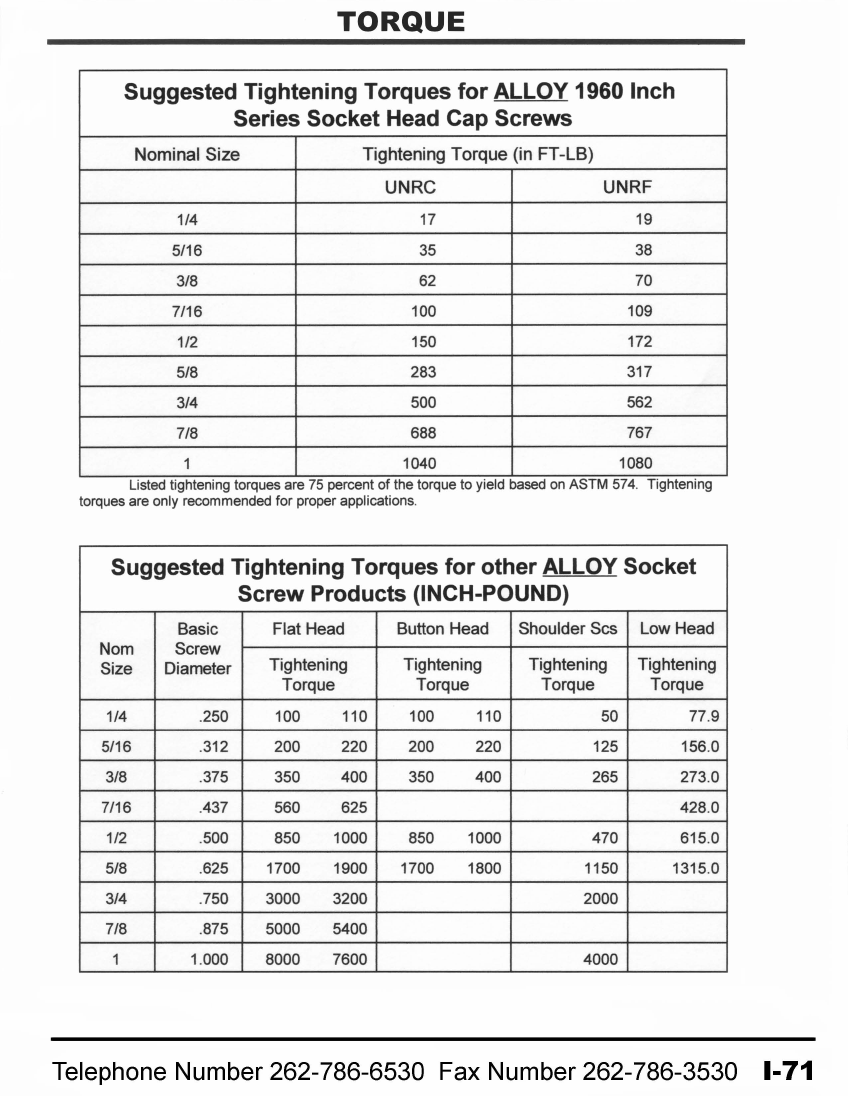

Web in this comprehensive guide, we'll take you through the essential features of a power drill and show you how to harness its capabilities effectively. By using the chart to select the appropriate torque setting for your application, you can prevent damage to the screw, the drill, or the workpiece. When it comes to cordless drills, the rule of thumb is that the higher the torque, the better. The clutch settings are typically marked on the drill itself, and each number corresponds to a specific torque setting. How to choose the right torque for your project.

By using the chart to select the appropriate torque setting for your application, you can prevent damage to the screw, the drill, or the workpiece. This may seem like common knowledge, but i hope it's helpful to some. Setting 2 is a medium speed/torque and can be used for drilling or driving. Remember to start with a low torque setting and gradually increase it as needed to avoid damaging the material or. Web generally speaking, most drills will have between 3 and 15 newton meters of torque. Web torque settings are an essential feature on cordless drills that dictate the amount of force used to tighten screws or drill holes. The correct torque setting depends on the size and type of the screw or bolt you are using. The process of using a clutch on a drill is a pretty simple one and since there is no preset specifications for the amount for each number provides and since every manufacture and every model of drill will be different, the process is pretty general and will work for nearly every drill. It’s important to use the correct torque setting to avoid damaging the material you are working with or stripping screws. First, you need to know that the torque is measured in newton meters or “hm”. Web the makita drill torque settings chart is a valuable tool that can help you achieve the best results when using your makita drill. Set the clutch to the desired torque level. Select the proper clutch setting. What is a good torque for cordless drill? That is, if the number is high, it means that the torque is also high at the moment.

Start By Locating The Torque Adjustment Ring On Your Drill.

In addition to that, though, there's a secondary application. This may seem like common knowledge, but i hope it's helpful to some. That is, if the number is high, it means that the torque is also high at the moment. Hammer rate (or blow rate):

This Is Because Higher Torque Levels Make It Easier To Drill Through Tougher Materials.

Web the torque rating is a standardized test that measures how much torque the drill produces in a very brief moment while it’s locked down. Check the manufacturer’s instructions or use a torque chart to determine the appropriate setting. Web the makita drill torque settings chart is a valuable tool that can help you achieve the best results when using your makita drill. Setting 2 is a medium speed/torque and can be used for drilling or driving.

The Numbers Are Designed With A Rotational Clutch.

Web how can i determine the correct torque setting for my drill? In position 2 will spin faster but with less torque so better for drilling holes. Set the clutch to the desired torque level. Web discover how to achieve optimal results by correctly utilizing drill torque settings in this comprehensive guide.

Web In Position 1 The Drill Will Spin More Slowly And Have The Most Torque (Best For Driving Screws).

This comprehensive guide will delve into every aspect of the drill torque settings chart, helping you understand its significance, interpret its data, and leverage it to enhance your drilling endeavors. Web we’ll explain how to adjust the torque or clutch settings on a drill and what the hammer settings on a cordless drill do. Web generally speaking, most drills will have between 3 and 15 newton meters of torque. Understanding torque is crucial to achieving precision when working with materials of different densities.

![Cordless Drill Torque Chart With [High Torque Drills 2024]](https://toolminer.com/wp-content/uploads/2020/03/Cordless-Drill-Torque-Chart-1536x1024.png)

![Cordless Drill Torque Chart With [High Torque Drills 2024]](https://toolminer.com/wp-content/uploads/2021/04/Research-Part-1-768x1126.jpg)

![Cordless Drill Torque Chart With [High Torque Drills 2021]](https://toolminer.com/wp-content/uploads/2021/04/Research-Part-3-1111x1536.jpg)