Web the primary ansi ratings related to gloves include cut resistance, abrasion resistance, puncture resistance, and impact protection. It is important to understand the protection levels associated with each standard as well as the most appropriate levels for. Web the new ansi standard now features nine cut levels significantly reducing the gaps between each level and better defining protection levels for the cut resistant gloves and sleeves with the highest gram scores. Web what are the levels of cut resistant gloves? Web discover the importance of ansi cut levels in our comprehensive guide.

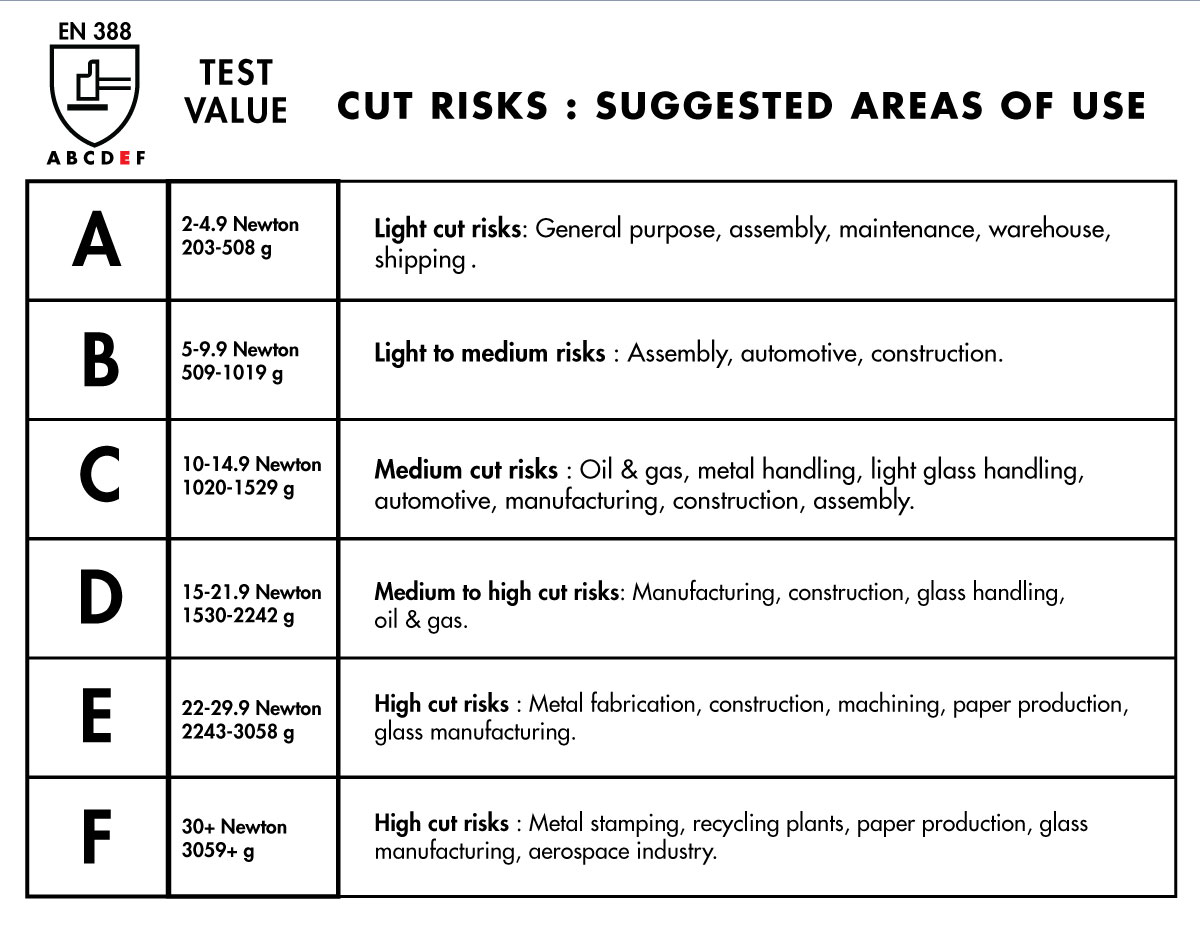

Web so, we’ve put together this handy infographic to help explain the different levels of cut resistance under the iso 13997 cut test method and what level of protection you would typically need for common cut hazard applications. Web understanding the ansi cut level chart is crucial for selecting gloves that provide adequate protection without compromising on dexterity or comfort. Assess the workplace environment and identify any potential hazards. Web the primary ansi ratings related to gloves include cut resistance, abrasion resistance, puncture resistance, and impact protection. To understand what each level might be good for, we’ve listed them below and added some descriptions of.

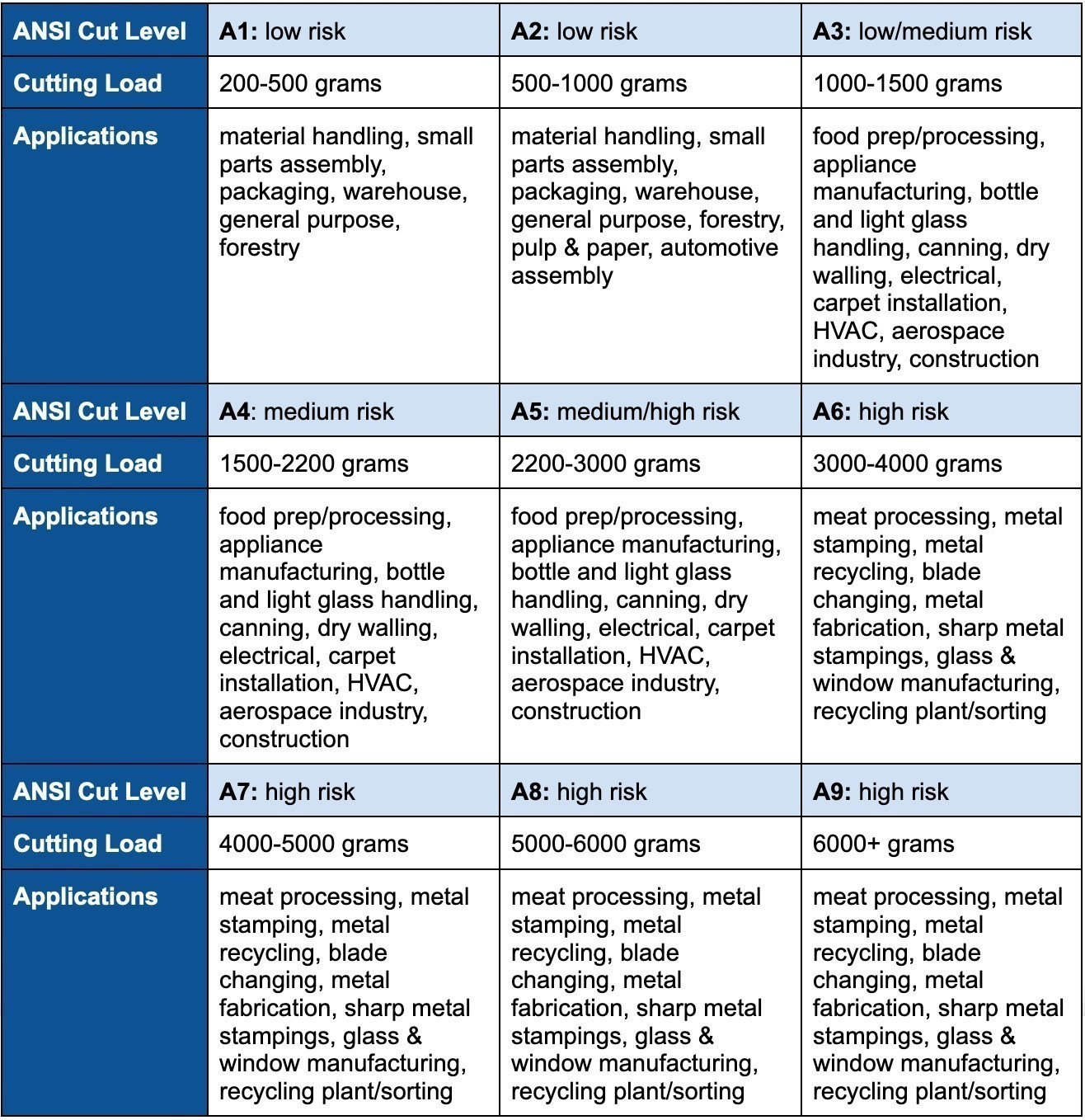

Assess the workplace environment and identify any potential hazards. Employers and workers can use this information to select gloves that provide the appropriate level of cut protection in a particular workplace. This chart categorizes gloves from level a1, offering minimal cut resistance, to level a9, designed for the most hazardous environments. Web understanding the ansi cut level chart is crucial for selecting gloves that provide adequate protection without compromising on dexterity or comfort. To understand what each level might be good for, we’ve listed them below and added some descriptions of.

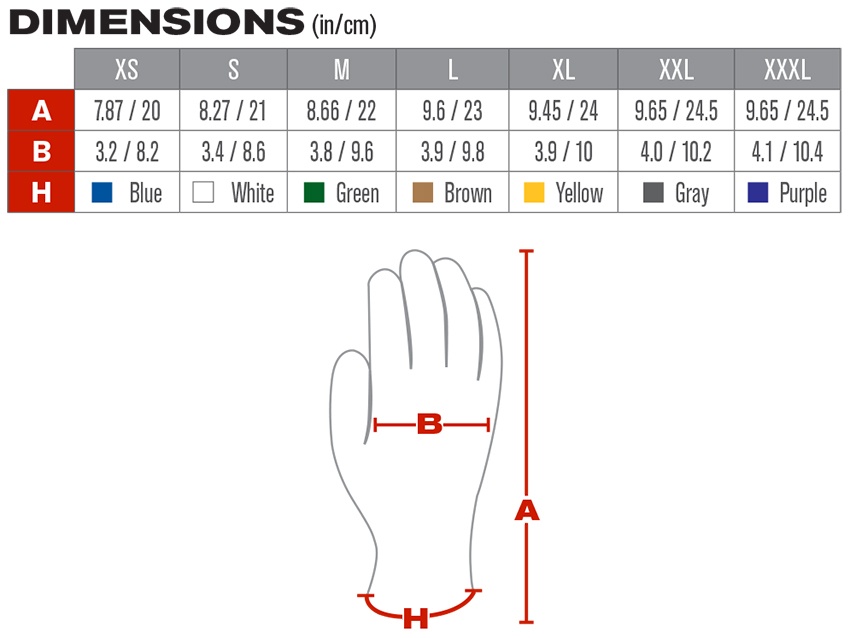

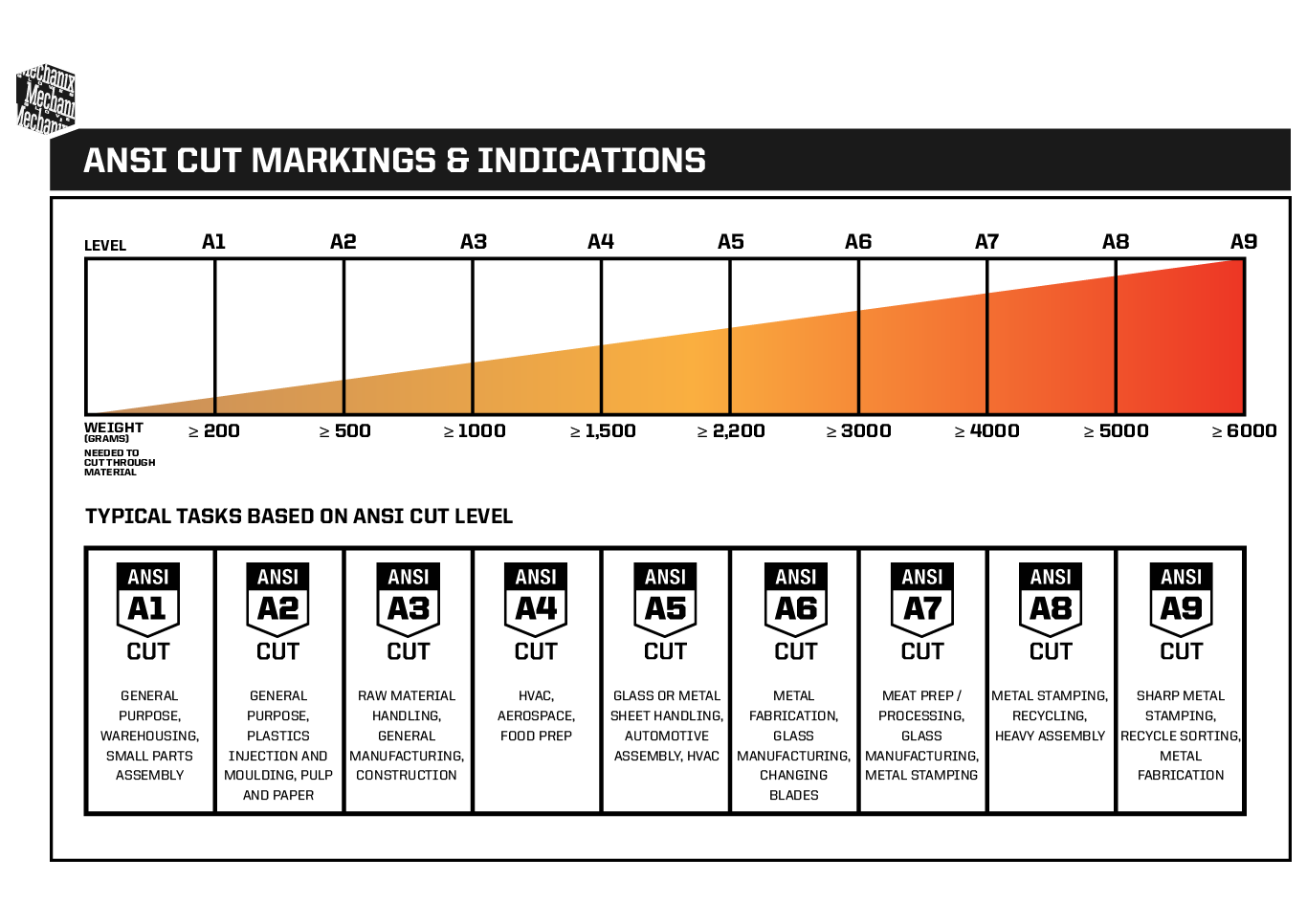

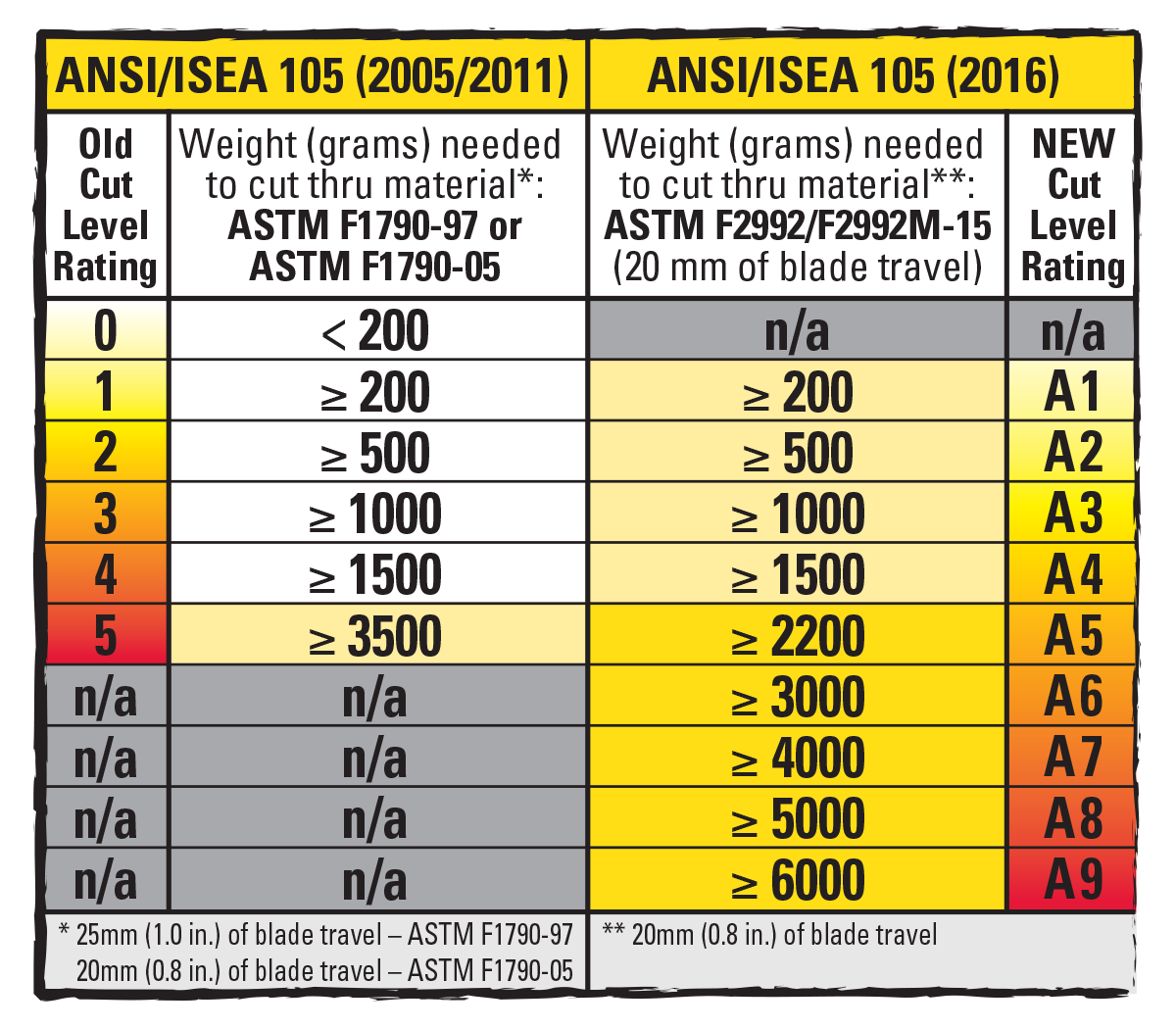

This chart categorizes gloves from level a1, offering minimal cut resistance, to level a9, designed for the most hazardous environments. How to choose the right cut protection. The graph below shows the differences between the old scale and the new scale. What level of cut protection is needed? It is important to understand the protection levels associated with each standard as well as the most appropriate levels for. Material handling, small parts assembly, packing, warehouse work, general purpose, construction. Employers and workers can use this information to select gloves that provide the appropriate level of cut protection in a particular workplace. Web understanding the ansi cut level chart is crucial for selecting gloves that provide adequate protection without compromising on dexterity or comfort. The ansi chart below also provides examples of applications of the various levels of cut resistance. Assess the workplace environment and identify any potential hazards. Here’s your quick guide to translating what the cuss all those symbols, letters and numbers actually mean. Below are questions to consider when evaluating available options: Flexible for dexterity and comfort puncture/abrasion resistant and grips when wet thick textured coating for best overall grip. Web discover the importance of ansi cut levels in our comprehensive guide. To understand what each level might be good for, we’ve listed them below and added some descriptions of.

Material Handling, Small Parts Assembly, Packing, Warehouse Work, General Purpose, Construction.

Web the new ansi standard now features nine cut levels significantly reducing the gaps between each level and better defining protection levels for the cut resistant gloves and sleeves with the highest gram scores. The graph below shows the differences between the old scale and the new scale. Web what are the levels of cut resistant gloves? To understand what each level might be good for, we’ve listed them below and added some descriptions of.

What Level Of Cut Protection Is Needed?

Often found on the cuff, this is where you can find the level at which the glove passes each risk. Assess the workplace environment and identify any potential hazards. Web if you want protection from minor cuts and your work, then this is the right rating for you. The ansi chart below also provides examples of applications of the various levels of cut resistance.

Web The Cut Resistance Level Of Gloves Meeting The Ansi 105 Standard Will Be Indicated On The Glove Label.

This chart categorizes gloves from level a1, offering minimal cut resistance, to level a9, designed for the most hazardous environments. Web the 2016 ansi cut level ratings indicate how many grams of cutting load a glove can withstand from a sharp blade before it gets penetrated. Employers and workers can use this information to select gloves that provide the appropriate level of cut protection in a particular workplace. Web understanding the ansi cut level chart is crucial for selecting gloves that provide adequate protection without compromising on dexterity or comfort.

Web So, We’ve Put Together This Handy Infographic To Help Explain The Different Levels Of Cut Resistance Under The Iso 13997 Cut Test Method And What Level Of Protection You Would Typically Need For Common Cut Hazard Applications.

Web the primary ansi ratings related to gloves include cut resistance, abrasion resistance, puncture resistance, and impact protection. It is important to understand the protection levels associated with each standard as well as the most appropriate levels for. Web discover how cut resistant gloves offer protection. Web for both ansi 105 and en 388, the badge tells all.