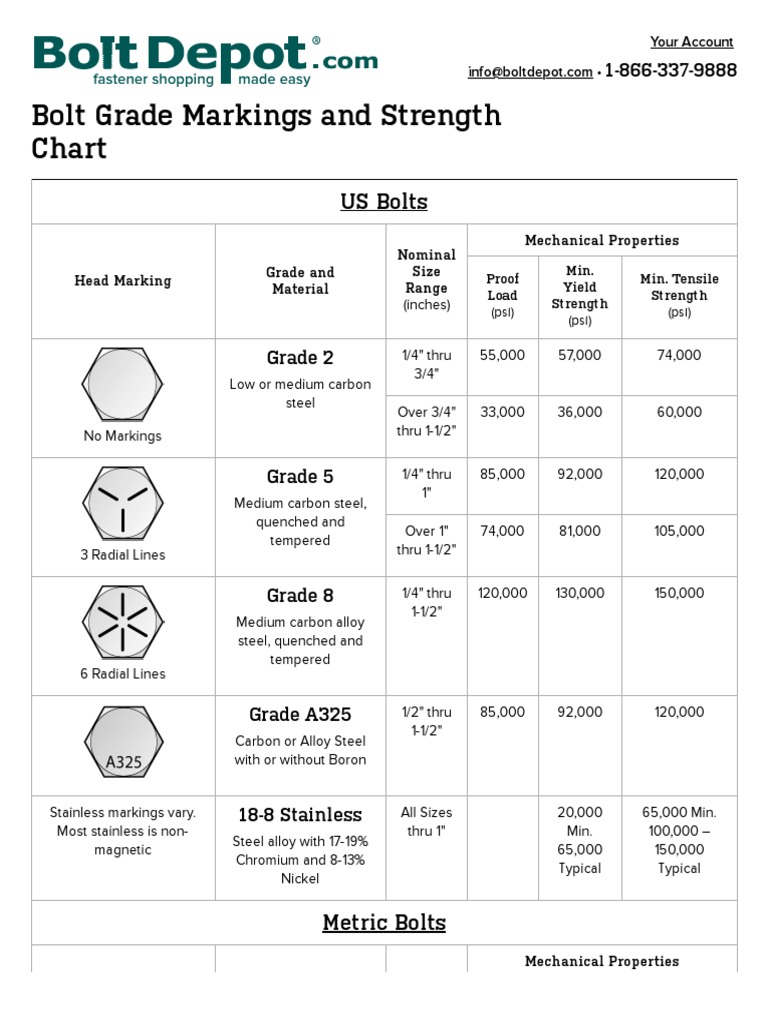

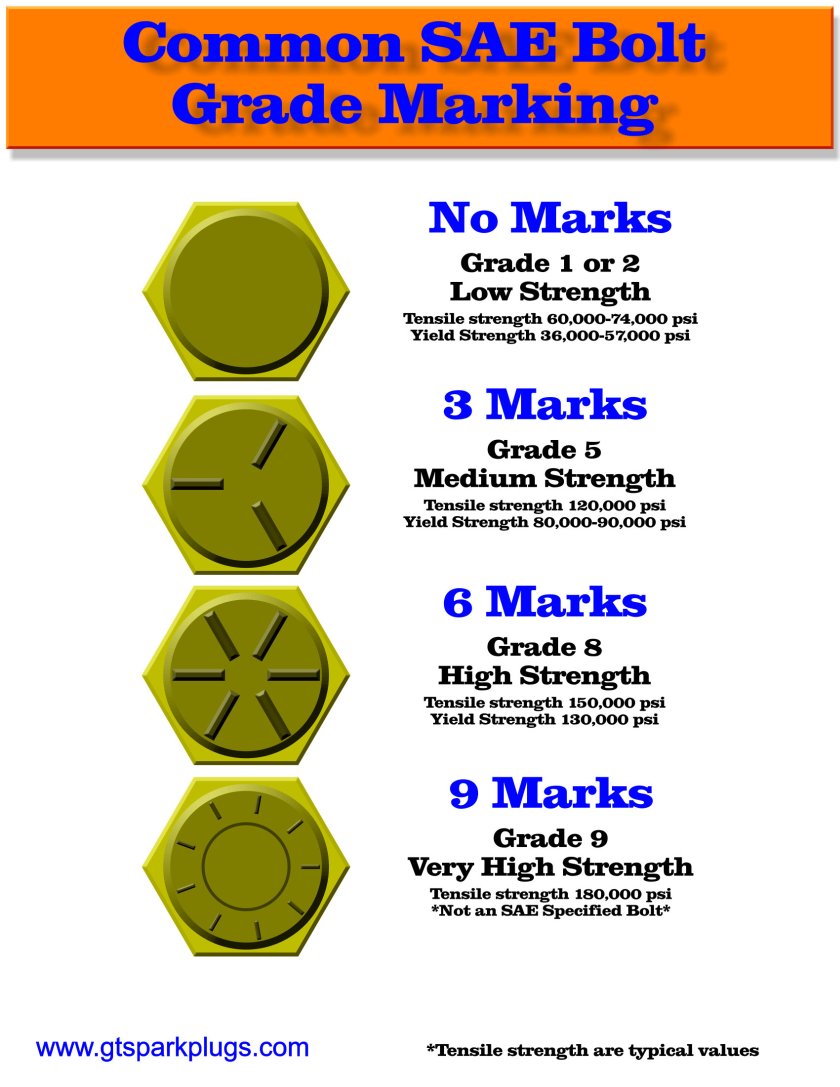

A guide to selecting the perfect bolt for your project. Web choosing the right grade. Which bolt grades are commonly used in construction, manufacturing, and. Web grade 2, 5, and 8 are the most common grades of fasteners according to the society of automotive engineers standard. Web 24 rows find the grades of bolts using the identification marks on the bolt's head and.

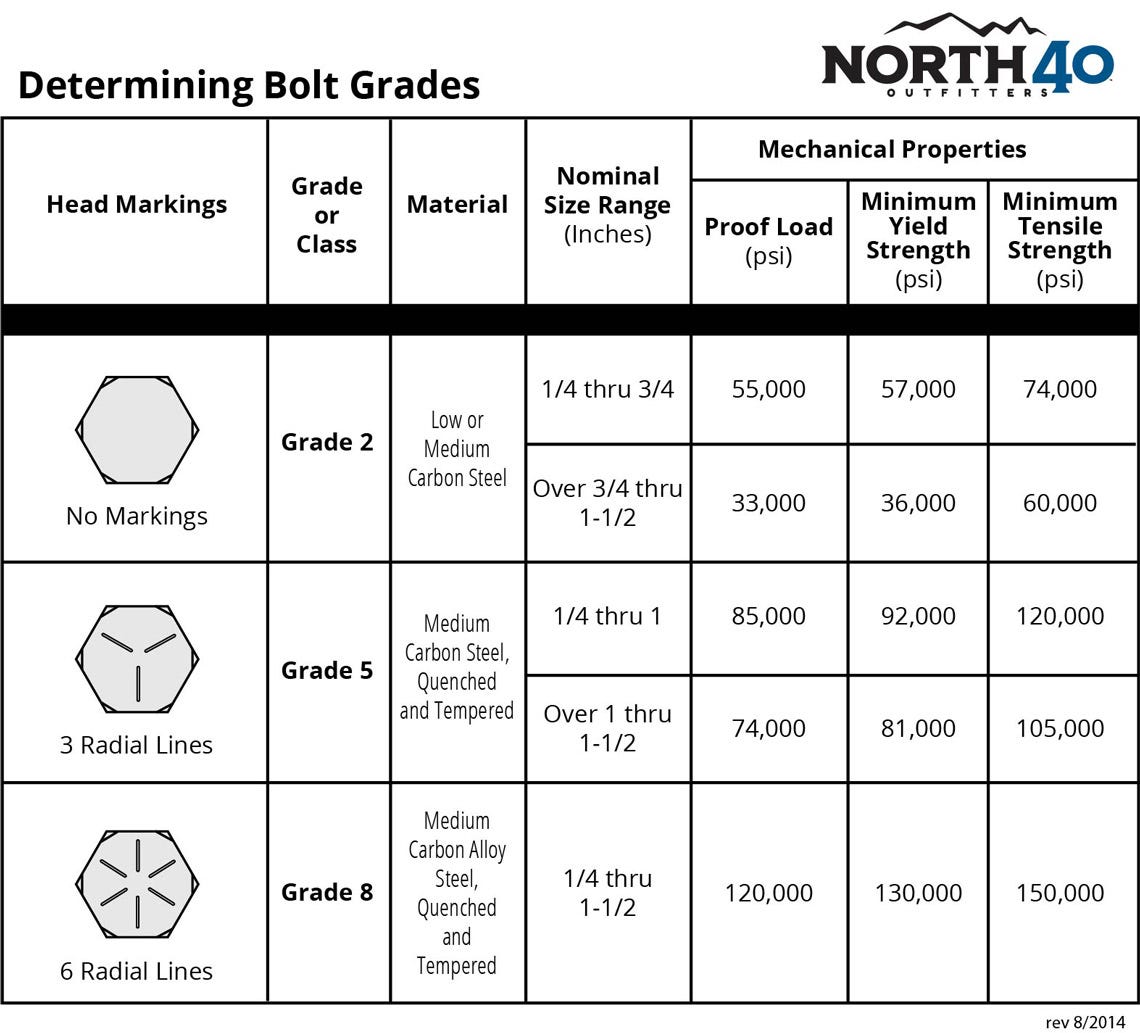

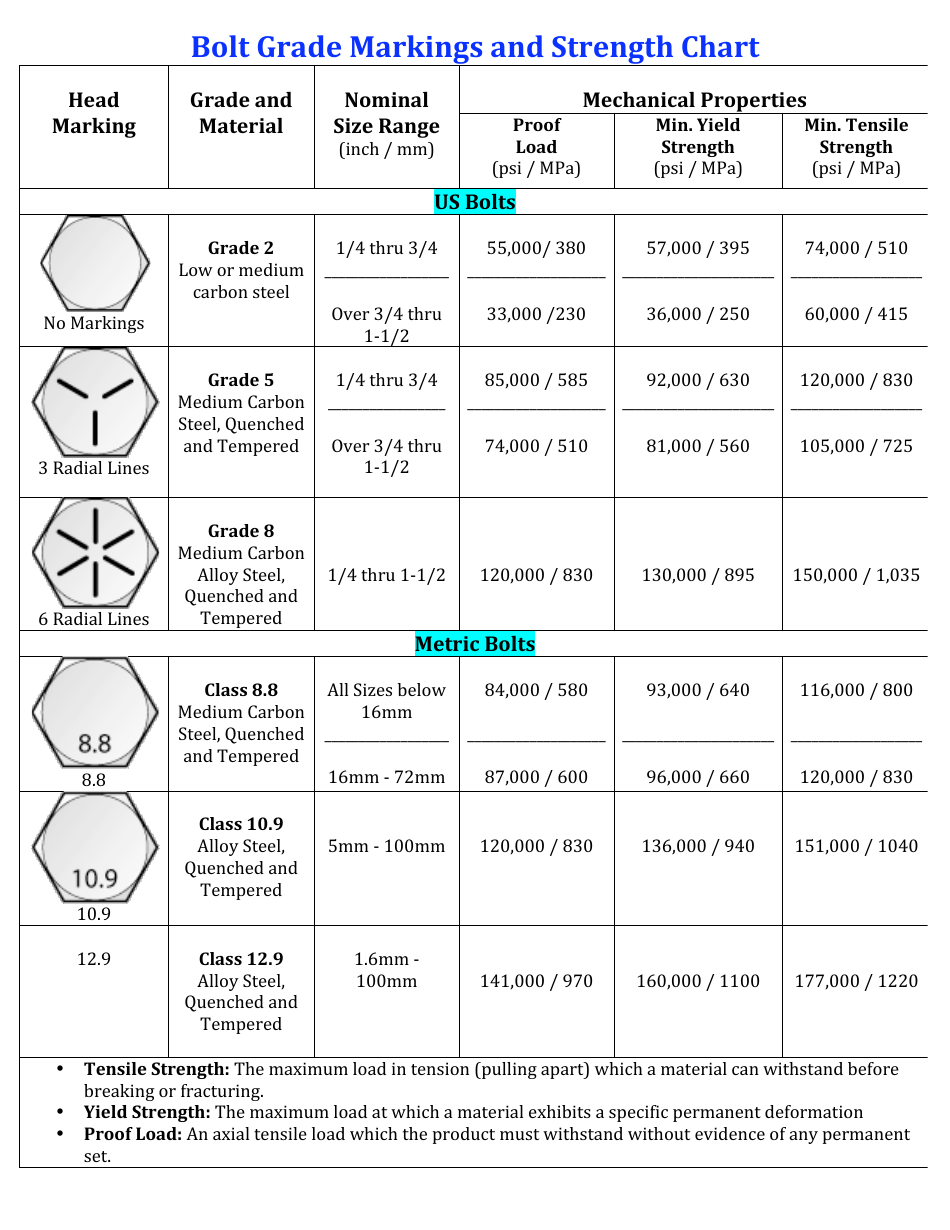

Web us bolts i grade and material grade 2 low or medium carbon steel grade 5 medium carbon steel, quenched and tempered grade 8 medium carbon alloy steel, quenched. The maximum load in tension (pulling apart) which a material can withstand before breaking or fracturing. Read this guide to choosing bolts and hardware that fit securely. Web grade 2, 5, and 8 are the most common grades of fasteners according to the society of automotive engineers standard. Web metric graded bolts are identified by the head markings on the top of the bolts, and the number will be marked.

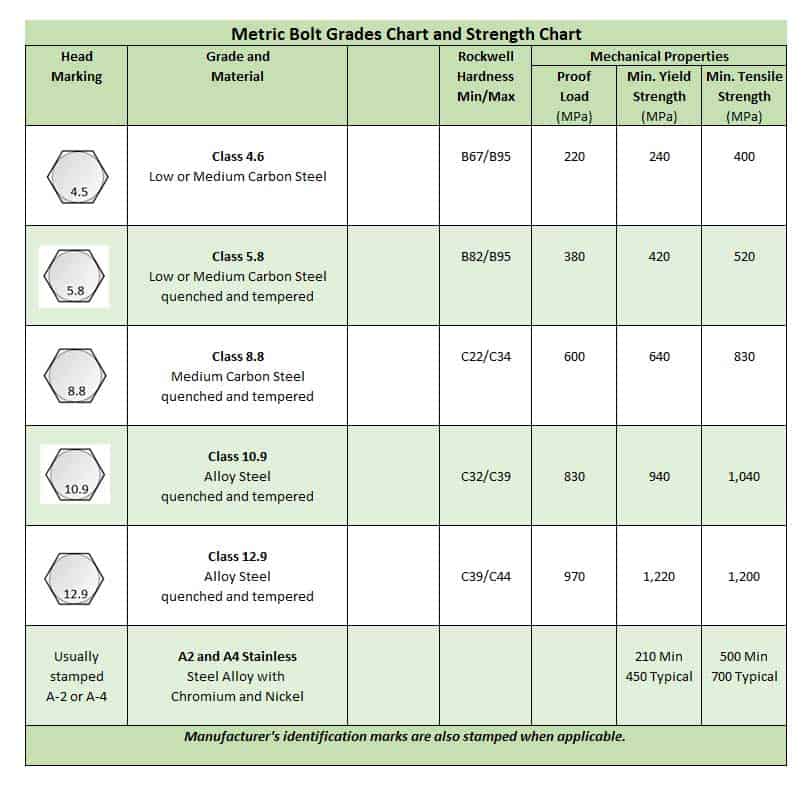

They are marked by their grade number, for instance, 8.8 or 10.9. 1 psi (lb/in2) = 6895 pa (n/m2) 1 inch = 25.4 mm. Web metric grades range from 3.6 to 12.9. Web 24 rows find the grades of bolts using the identification marks on the bolt's head and. The nut manufacturer, at his option, may add other markings to.

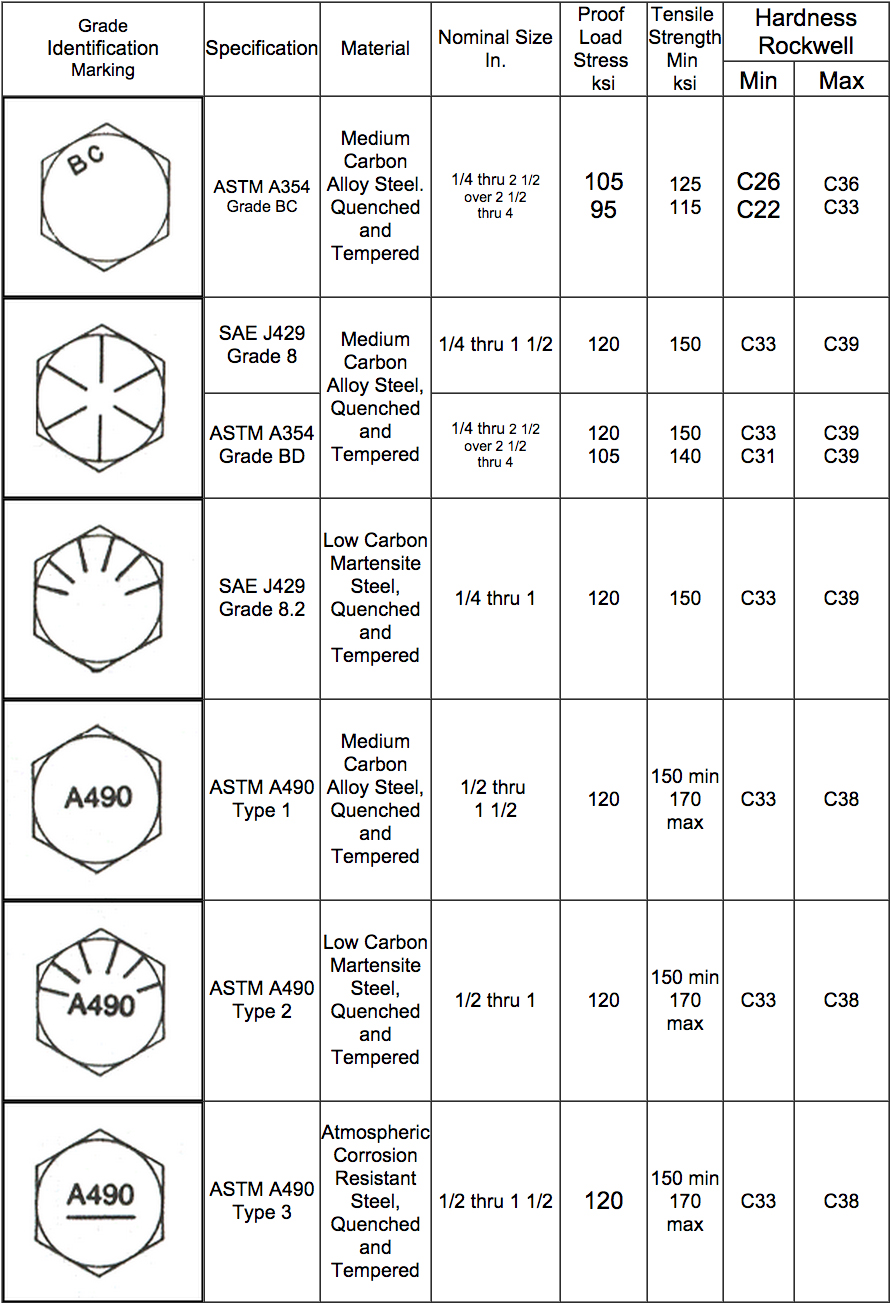

Web properties shown are those of coarse 8‐thread heavy hex nuts. Satisfaction guaranteedfast order turnaroundtalk to bolt experts Which bolt grades are commonly used in construction, manufacturing, and. The higher the grade is, the stronger the. Web this guide is designed to help you understand different bolt grades and head types. Web the bolt grades and strength chart outlines the physical and mechanical properties of various grades of bolts. It includes information on the grade of the bolt, the tensile. Web we will outline the structure of the bolt grades chart, which typically includes columns for grade numbers, properties (such as tensile strength and yield strength), and common. 1 psi (lb/in2) = 6895 pa (n/m2) 1 inch = 25.4 mm. A class 8.8 would have an 8.8 mark, a class 10.9. Web to help you choose the right bolt strength, here is a chart illustrating specifications for different bolt strengths based on their grade or classification: For metric bolts strength is according iso 898 mechanical properties of fasteners made of carbon steel and alloy. Web choosing the right grade. Hardnesses are brinell hardness numbers. They are marked by their grade number, for instance, 8.8 or 10.9.

The Maximum Load In Tension (Pulling Apart) Which A Material Can Withstand Before Breaking Or Fracturing.

Web astm & sae grade markings for steel bolts and screws. Web grade 2, 5, and 8 are the most common grades of fasteners according to the society of automotive engineers standard. It includes information on the grade of the bolt, the tensile. Web we will outline the structure of the bolt grades chart, which typically includes columns for grade numbers, properties (such as tensile strength and yield strength), and common.

Web Printable Chart For Easy Comparison Between Metric Bolt Classes And Us Grades Equivalents.

Web us bolts i grade and material grade 2 low or medium carbon steel grade 5 medium carbon steel, quenched and tempered grade 8 medium carbon alloy steel, quenched. Popular internal searches in the engineering toolbox. For metric bolts strength is according iso 898 mechanical properties of fasteners made of carbon steel and alloy. An axial tensile load which the product must withstand.

Read This Guide To Choosing Bolts And Hardware That Fit Securely.

Higher numbers represent stronger bolts. A guide to selecting the perfect bolt for your project. Web metric grades range from 3.6 to 12.9. Web the bolt grades and strength chart outlines the physical and mechanical properties of various grades of bolts.

Web Choosing The Right Grade.

Web 38 rows hex bolt identification, markings and strength chart. Web 24 rows find the grades of bolts using the identification marks on the bolt's head and. Web bolt grade markings & strength. Bolt & screw size, inches.

![Bolt Grades Chart and Strengths [ Quick Reference + PDF ] CNCCookbook](https://www.cnccookbook.com/wp-content/uploads/2022/09/img_631f76b82ca58.png)