Both dynamic and static load ratings indicating the maximum load capacity. The main factors to be considered when selecting the correct type are: Axial (thrust) (parallel to the shaft) loads: Web the bearing size chart helps identify the dimensions and specifications of bearings, making it a crucial tool for selection. By providing detailed information on inner diameter, outer diameter, and width, it assists in matching bearings to specific applications.

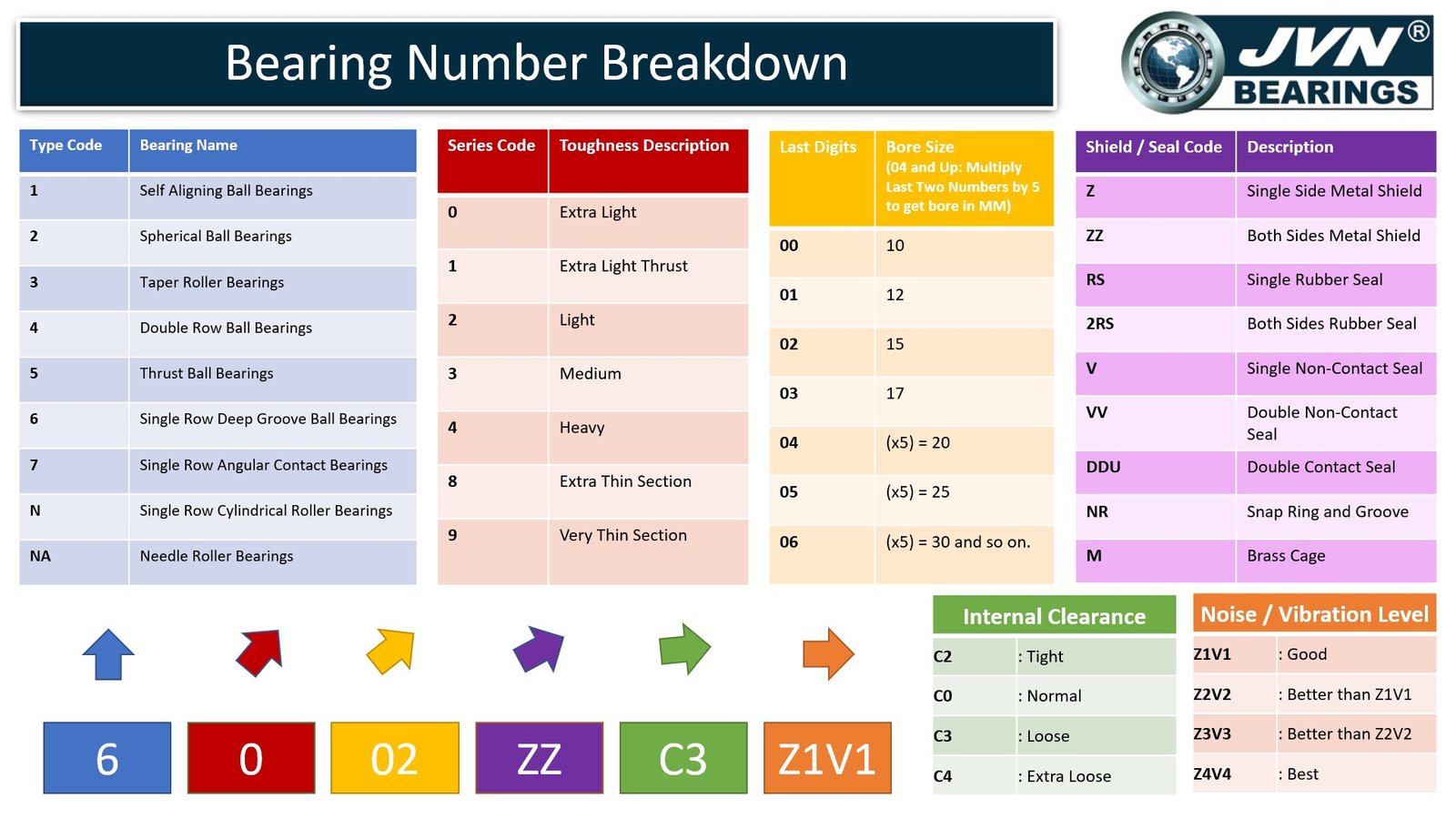

By the end, you’ll understand the essential codes that keep machines running efficiently. Web there are many types of bearings, and manufacturing processes with many fine points of difference according to the type of bearing. Combined radial and axial loads. These bearings are often chosen for applications with high dynamic misalignment. Detailed measurements including id, od, and width.

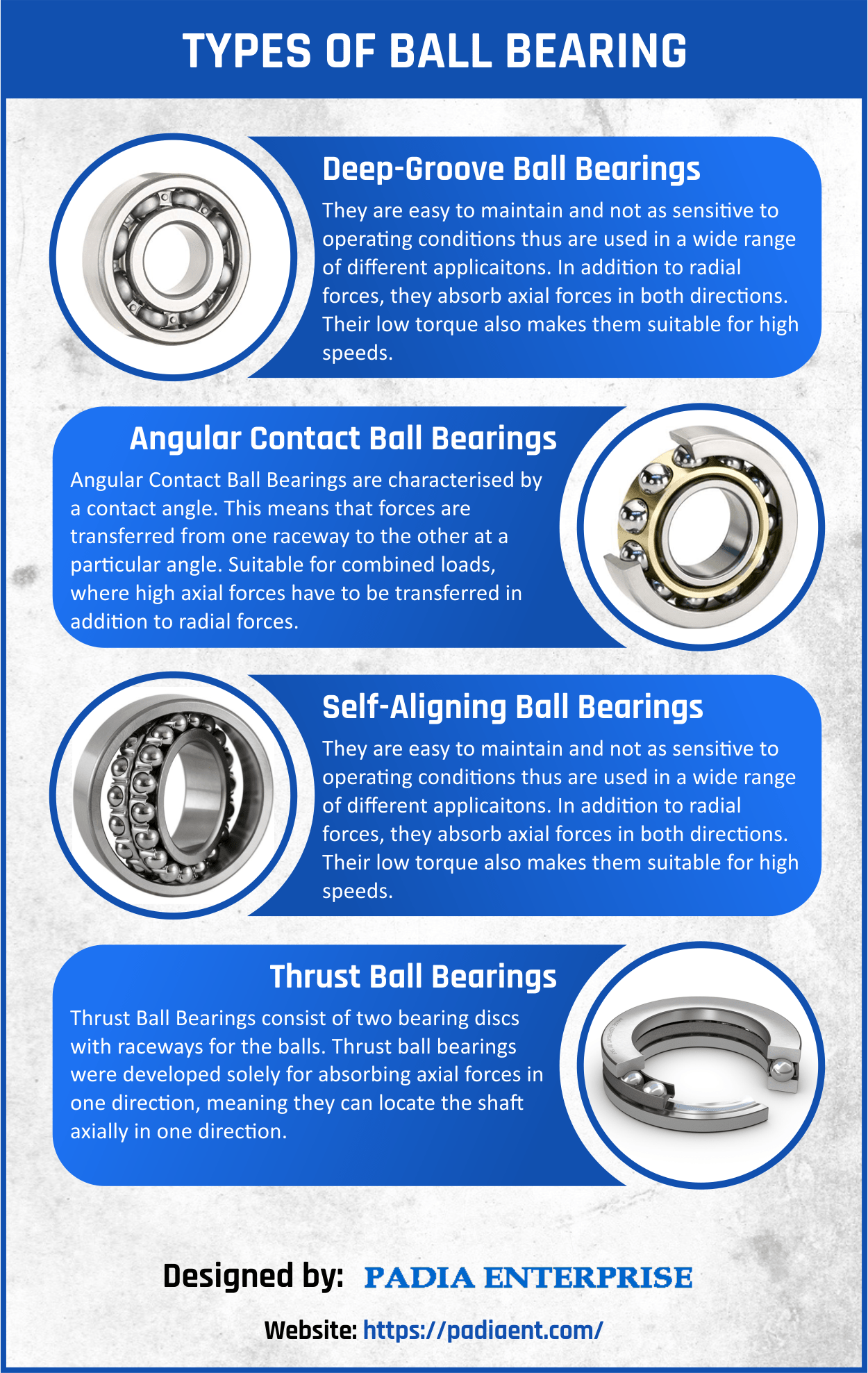

Understanding these distinctions is crucial for selecting the right bearing for specific machinery and equipment needs, ensuring optimal performance and durability. Web radial (perpendicular to the shaft) and light loads: Web the designations of most skf rolling bearings follow a designation system. There are many different types of bearings, each with its own unique set of benefits and applications. Web the bearing size chart helps identify the dimensions and specifications of bearings, making it a crucial tool for selection.

Bearings typically allow for low friction movement and can be found in a variety of applications. Web have you ever wondered how engineers ensure the smooth operation of machinery? It’s important to note that there are many variations and specialized designs within each bearing type to suit specific performance requirements and. Detailed measurements including id, od, and width. The direction of load is a primary factor in bearing type selection. They facilitate smooth operations in. By the end, you’ll understand the essential codes that keep machines running efficiently. Identifies the type of bearing (e.g., deep groove ball bearing, spherical roller bearing). Generally speaking, bearing manufacturing consists of the processes of forging, turning, heat treatment, grinding, and assembly. Bearings play a crucial role. By providing detailed information on inner diameter, outer diameter, and width, it assists in matching bearings to specific applications. Web the most common bearing application is the ball bearing. Generally, all types of machinery are provided with supports for rotating shafts. Web this chart provides a basic overview of some common bearing types, their features, and typical applications. Radial bearings are some of the most common types of bearings on the market.

Web Bearing Types, Including Spherical Roller Bearings, Spherical Roller Thrust Bearings, And The Carb™ Toroidal Roller Bearings.

Web have you ever wondered how engineers ensure the smooth operation of machinery? Web there are many types of bearings, and manufacturing processes with many fine points of difference according to the type of bearing. Axial (thrust) (parallel to the shaft) loads: Web matrix 1 provides an overview of the suitability of various bearing types for different bearing arrangements.

An Example Of Dynamic Misalignment Would Be A Vibrating Screen With Rotating Imbalance And Therefore Rotating Deflection Of The Shaft.

Detailed measurements including id, od, and width. They facilitate smooth operations in. Web each bearing type has characteristic properties that make it more or less suitable for use in a given application. This guide will dive into different types of bearings and their uses, along with the definition, function, and classification of bearings.

Web Before Determining The Best Bearing For Your Application, It Is Necessary To Identify The Bearing Type And Characteristics.

The manufacturing process for deep groove ball bearings is shown below. It’s important to note that there are many variations and specialized designs within each bearing type to suit specific performance requirements and. Web these help narrow down the bearing selecting process. Bearings typically allow for low friction movement and can be found in a variety of applications.

Choose An Angular Contact Bearing.

By providing detailed information on inner diameter, outer diameter, and width, it assists in matching bearings to specific applications. Web the bearing size chart helps identify the dimensions and specifications of bearings, making it a crucial tool for selection. Shaft and housing fits for electric motor bearings. This movement is either rotary (shaft rotating within a mount) or linear (one surface moving along another).

![15 Types of Bearings and Their Applications [Pictures & PDF]](https://www.theengineerspost.com/wp-content/uploads/2018/09/Types-of-Bearings.jpg)