Use ac (alternating current) when welding aluminum and magnesium. Web one of the best choices for welding aluminum is a tig welder that runs on ac power, and you will get many of the most excellent prices. The primary gas used is argon and in some applications on thick aluminum when additional penetration. However, as the thickness of the base material is higher, the above rule is. It caters to different material types and thicknesses for effective welding.

Web see the chart below for recommended flow rates. Web when tig welding aluminum, making some adjustments to your weld settings, like balance and frequency, can make a big difference in the final weld. However, as the thickness of the base material is higher, the above rule is. Any trace of oil can cause porosity and may inhibit the flow of molten metal. The gas flow rate is crucial to ensure the joint's durability, integrity, and quality.

Many operators, especially those new to aluminum welding, may not. Tig welding, or tungsten inert gas welding, demands precision and control over various settings for optimal results. Tig welding aluminum requires that everything be squeaky clean, and this is particularly important with aluminum. I recommend getting in the habit of using a degreaser, since even the invisible oil from your hands can cause. The primary gas used is argon and in some applications on thick aluminum when additional penetration.

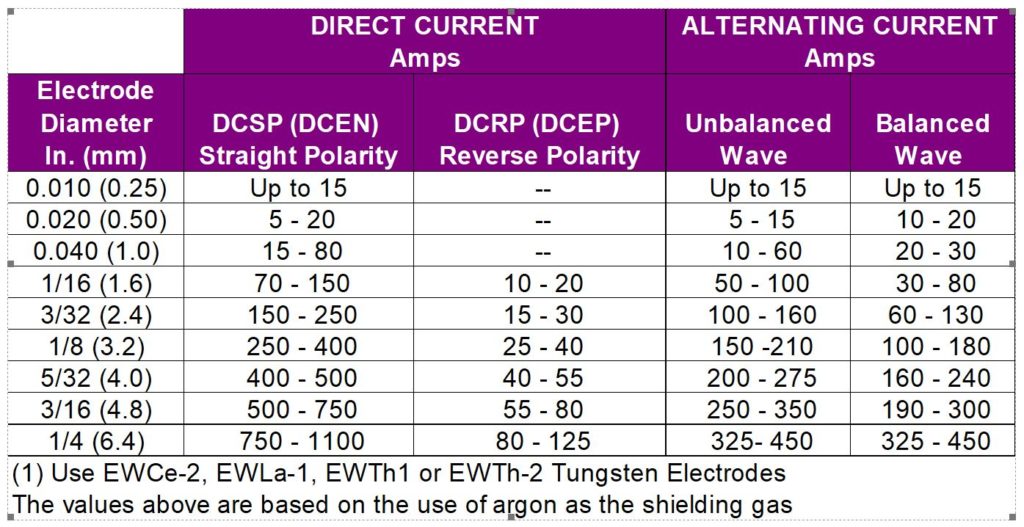

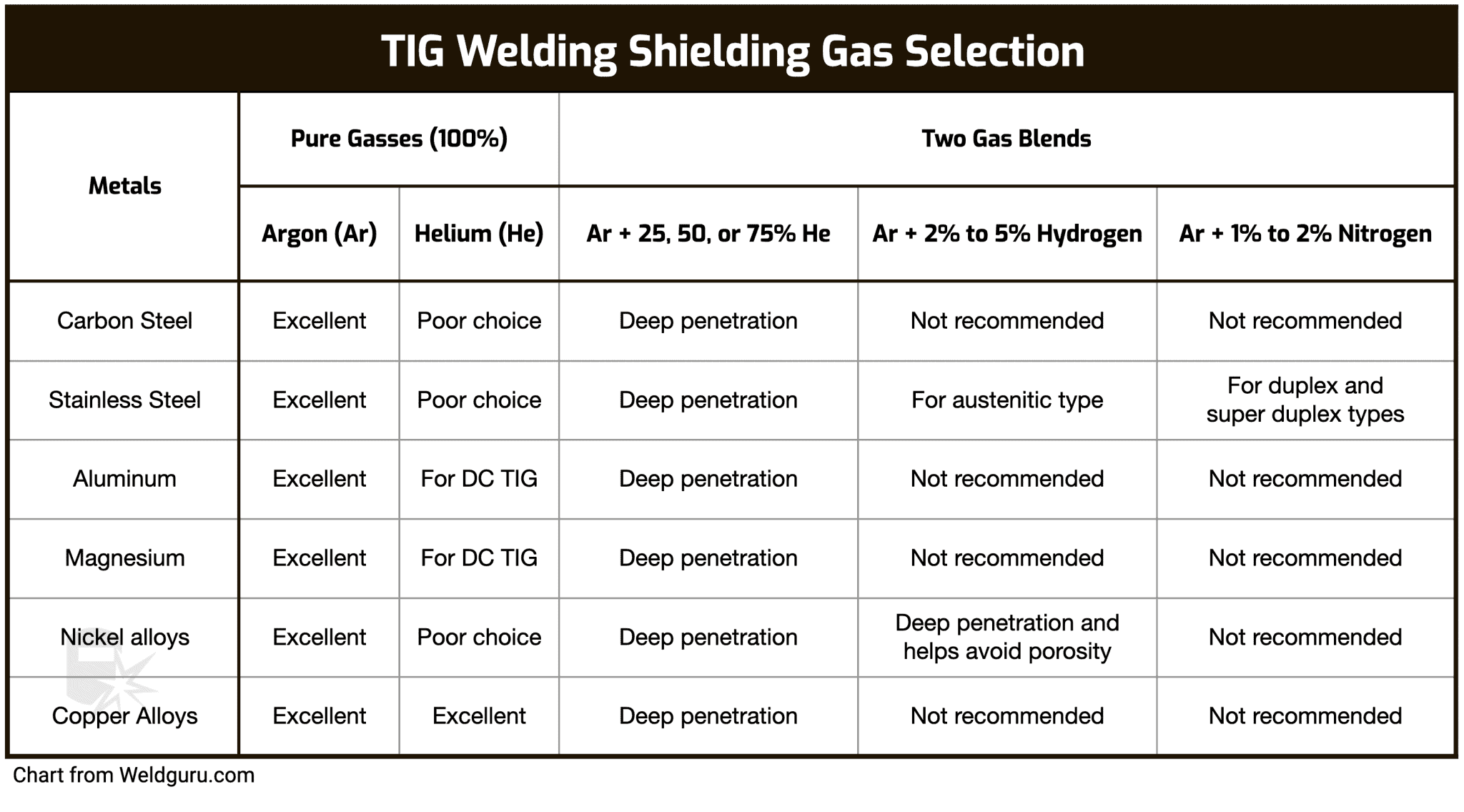

The chart usually includes the current range, polarity, filler metal type, shielding gas type, and tungsten electrode size. It caters to different material types and thicknesses for effective welding. Turn on the machine and the rear panel; The exact settings will depend on the thickness of the material, the nature of the weld, and the nature of the joint you are welding. An led green light will ensure you have the chosen option; However, as the thickness of the base material is higher, the above rule is. Web what settings do i use to tig weld aluminum? Web a tig welding settings chart provides essential parameters like amperage, voltage, and gas flow. According to these charts, mild steel requires the most amperage (not aluminum), and also the fastest travel speed. Before getting started, there are a few important settings you need to understand and adjust, including the current, gas flow rate and amperage. Web one important rule for choosing proper amperage for tig welding aluminum is to use 1 ampere for every thousandth (1/1000) of the aluminum thickness. The aluminum settings require you to use pure tungsten or thoriated tungsten with a green, red and yellow band. Web tig welding aluminum doesn’t need to be intimidating. Any trace of oil can cause porosity and may inhibit the flow of molten metal. With a little practice — and some basic best practices to help beginning welders — you can produce the results you want.

It Outlines The Optimal Settings Based On Material Thickness And Joint Type.

Many operators, especially those new to aluminum welding, may not. Do you tig weld aluminum on ac or dc? Tap the bottom row buttons; Use ac (alternating current) when welding aluminum and magnesium.

For Example, To Tig Weld An Aluminum Piece That Is 1/8 Inch In Thickness Would Require 125 Amperes.

Web download the app version of the weld setting calculator for easy reference! The primary gas used is argon and in some applications on thick aluminum when additional penetration. Web for the best appearance, highest quality and leak free welds on aluminum, ac tig welding is the process of choice. Tig welding aluminum requires that everything be squeaky clean, and this is particularly important with aluminum.

I Recommend Getting In The Habit Of Using A Degreaser, Since Even The Invisible Oil From Your Hands Can Cause.

However, as the thickness of the base material is higher, the above rule is. Web a tig welding chart visually represents the welding parameters needed to achieve a specific weld. Some of the options need. Web in addition to properly controlling heat, consider these seven tips to optimize results when welding aluminum with gtaw.

Web What Settings Do I Use To Tig Weld Aluminum?

Any trace of oil can cause porosity and may inhibit the flow of molten metal. Web settings for tig welding aluminum. Gas flow rates for tig welding. The chart usually includes the current range, polarity, filler metal type, shielding gas type, and tungsten electrode size.